Test: Mechanical Properties of Materials - 3 - Mechanical Engineering MCQ

30 Questions MCQ Test - Test: Mechanical Properties of Materials - 3

A material capable of absorbing large amount of energy before fracture is known as

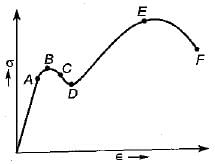

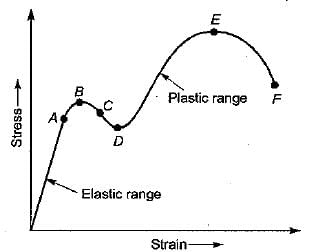

The following figure shows the stress-strain curve for tensile test on a mild steel specimen.

Q. The upper yield point is represented by the point

Select the proper sequence

1. Proportional limit

2. Elastic limit

3. Yielding

4. Failure

The stress-strain curve for glass during tensile test would exhibit

The impact strength of a material is an index of its

What are the materials which show direction dependent properties?

A material has identical properties in all directions, it is said to be

The material in which large deformation is possible before the absolute failure or rupture is termed as

What is the phenomenon of progressive extension of the material i.e. strain increasing with the time at a constant load, called?

The stress level, below which a material has a high probability of not failing under reversal of stress, is known as

The energy absorbed in a body, when it is strained within the elastic limits, is known as

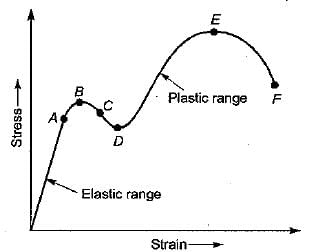

Toughness for mild steel under uniaxial tensile loading is given by the shaded portion of the stress-strain diagram as shown in

Which one of the following pairs is NOT correctly matched?

The linear relation between the stress and strain of a material is valid until

Limit of proportionality depends upon

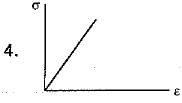

The stress-strain curve for an ideally plastic materia! is

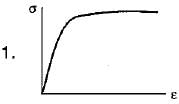

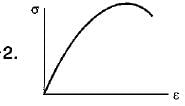

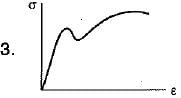

Match List-I (Materials) with List-II (Stress-Strain curves) and select the correct answer using the codes given below the lists:

List-I

A. Mild steel

B. Pure copper

C. Cast iron

D. Pure aluminium

List-II

Codes:

A B C D

(a) 3 1 4 1

(b) 3 2 4 2

(c) 2 4 3 1

(d) 3 2 4 1

Match list - I with list - II and select the correct answer using the codes below:

List - I

A. Ductility

B. Brittleness

C. Tenacity

D. Toughness

List - II

1. Failure without warning

2. Drawn permanently over great changes of shape without rupture.

3. Absorption of energy at high stress without rupture.

4. High tensile strength

Which one of the following properties cannot be evaluated by static tension test?

The percentage elongation of a material as obtained from static tension test depends upon the

Modular ratio of two materials is the ratio of

Proof resilience per unit volume of a material is known as .

An axial residual compressive stress due to a manufacturing process is present on the outer surface of a rotating shaft subjected to bending. Under a given bending load, the fatigue life of the shaft in the presence of the residual compressive stress is