Machine Design - 1 - Mechanical Engineering MCQ

20 Questions MCQ Test SSC JE Mechanical Mock Test Series 2025 - Machine Design - 1

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

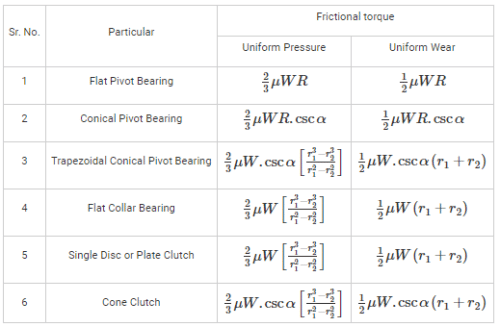

The frictional torque transmitted by a disc or plate clutch is same as that of ________ bearing.

A lead screw with half nuts in a lathe, free to rotate in both directions has

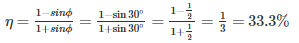

The maximum efficiency of a screw jack having square threads and friction angle of 30° will be:

The most suitable bearing for carrying very heavy loads with slow speed is _____.

The valve rod in a steam engine is connected to an eccentric rod by

Two shafts show axes are not in the same straight line and are not parallel but intersect each other. Which of the following couplings can be used for this type of shafts?

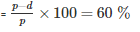

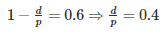

If the tearing efficiency of a riveted joint is 60%, then ratio of rivet hole diameter to the pitch of rivets is _____.

What is the stress to which a metal is subjected indefinitely to the stress reversal without rupture called?

In a multiple V belt drive, when a single belt is damaged, it is preferable to change the complete set to _____.

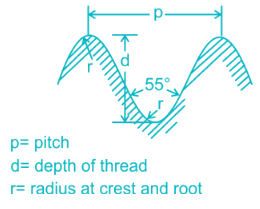

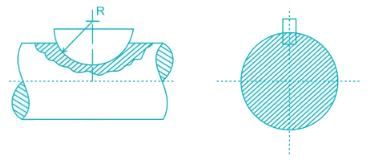

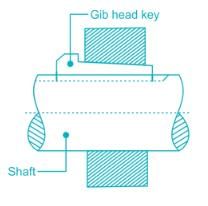

A key made from a cylindrical disc having segmental cross-section, is known as

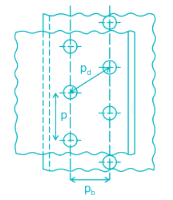

The pressure distribution in the uniform wear theory is ________.

|

3 videos|1 docs|55 tests

|

|

3 videos|1 docs|55 tests

|