Past Year Questions: Cutting Tool Geometry And Tool Life - Mechanical Engineering MCQ

30 Questions MCQ Test - Past Year Questions: Cutting Tool Geometry And Tool Life

Cutting tools are provided with large positive rake angle mainly for

[ME 1987]

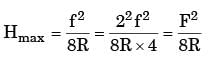

In turning operation the feed rate could be doubled to increase the metal removal rate. To keep the same level of surface finish, the nose radius of the tool has to be

[ME 1989]

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

The effect of rake angle on the mean friction angle in machining can be explained by

[ME 1992]

The rake angle in drill

[ME 1996]

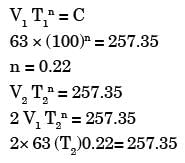

Tool life of a 10 hours is obtained when cutting with a single point tool at 63 m/min. If Taylor's constant C = 257.35, tool life on doubling the velocity will be

[ME 1996]

Helix angle of fast helix drill is normally

[ME 1997]

For turning NiCr alloy steel at cutting speeds of 64 m/min and 100 m/min, the respective tool lives are 15 min-and 12 min. The tool life for a cutting speed of 144 m/min is

[ME 2001]

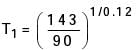

Tool life testing on a lathe under dry cutting conditions gauge n and C of Taylor tool life equation as 0.12 and 130 m/min. respectively. When a coolant was used, C increased by 10%.The increased tool life with the use of coolant at a cutting speed of 90 m/min is

[ME 2001]

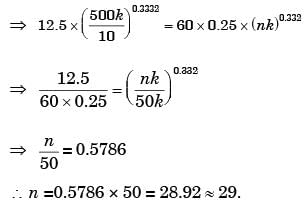

A batch of 10 cutting tools could produce 500 components while working at 50 rpm with a tool feed of 0.25 mm/rev and depth of cut of 1 mm. A similar batch of 10 tools of the same specification could produce 122 components while working at 80 rpm with a feed of 0.25 mm/rev and 1 mm depth of cut. How many components can be produced with one cutting tool at 60 rpm?

[ME 2003]

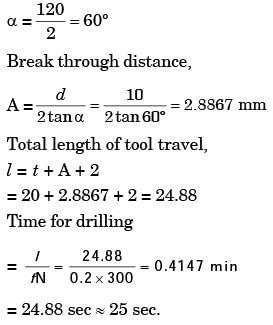

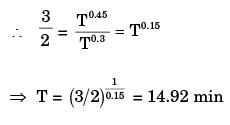

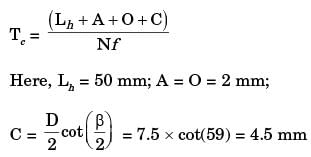

Through holes of 10 mm diameter are to be drilled in a steel plate of 20 mm thickness. Drill spindle speed is 300 rpm, feed 0.2 mm/rev and drill point angle is 120°. Assuming drill over travel of 2 mm, the time for producing a hole will be

[ME 2004]

In a machining operation, doubling the cutting speed reduces the tool life to 1/8th of the original value. The exponent n in Taylor's tool life equation VTn = C. is

[ME 2004]

A 600 mm x 30 mm flat surface of a plate is to be finish machined on a shaper. The plate has been fixed with the 600 mm side along the tool travel direction. If the tool over-travel at each end of the plate is 20 mm, average cutting speed is 8 m/min, feed rate is 0.3 mm/stroke and the ratio of return time to cutting time of the tool is 1 : 2, the time required for machining will be

[ME 2005]

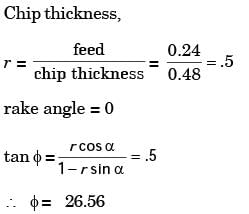

In orthogonal turning of a low carbon steel bar of diameter 150 mm with uncoated carbide tool, the cutting velocity is 90 m/min. The feed is 0.24 mm/rev and the depth of cut is 2 mm. The chip thickness obtained is 0.48 mm. If the orthogonal rake angle is zero and the principal cutting edge angle is 90°, the shear angle in degree is

[ME 2007]

In orthogonal turning of medium carbon steel, the specific machining energy is 2.0 J/mm3. The cutting velocity, feed and depth of cut are 120 m/min, 0.2 mm/rev and 2 mm respectively.The main cutting force in N is

[ME 2007]

In orthogonal turning of low carbon steel pipe with principal cutting edge angle of 90°, the main cutting force is 1000 N and the feed force is 800 N. The shear angle is 25° and orthogonal rake angle is zero. Employing Merchants theory, the ratio of friction force to normal force acting on the cutting tool is

[ME 2007]

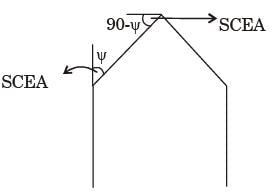

In a single point turning tool, the side rake angle and orthogonal rake angle are equal. ϕ is the principal cutting edge angle and its range is 0° ≤ f ≤ 90°. The chip flows in the orthogonal plane. The value of ϕ is closest to

[ME 2008]

Friction at the tool-chip interface can be reduced by

[ME 2009]

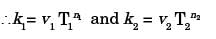

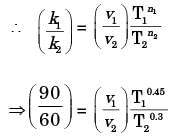

For tool A, Taylor's tool life exponent (n) is 0.45 and constant (K) is 90. Similarly for tool B, n = 0.3 and K = 60. The cutting speed (in 'm/ min) above which tool A will have a higher tool life than tool B is

[ME 2010]

A single-point cutting tool with 12° rake angle is used to machine a steel work-piece. The depth of cut, i.e. uncut thickness is 0.81 mm. The chip thickness under orthogonal machining condition is 1.8 mm. The shear angle is approximately

[ME 2011]

In a single pass drilling operation, a through hole of 15 mm diameter is to be drilled in a steel plate of 50 mm thickness. Drill spindle speed is 500 rpm, feed is 0.2 mm/rev and drill point angle is 118°, Assuming 2 mm clearance at approach and exit, the total drill time (in seconds) is

[ME 2012]

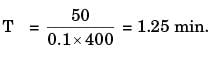

A hole of 20 mm diameter is to be drilled in a steel block of 40 mm thickness. The drilling is performed at rotational speed of 400 rpm and feed rate of 0.1 mm/rev. The required approach and over run of the drill together, is equal to the radius of drill. The drilling time (in minute) is

[ME 2014,Set-2]

The preferred option for holding an odd-shaped workpiece in a centre lathe is

[ME 2018,Set-2]

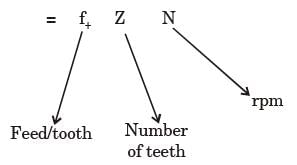

Feed rate in slab milling operation is equal to

[ME 2018,Set-2]

lf the number of double strokes per minute in a shaper is calculated by (0.643 × Cutting speed in mm/min)/length of the stroke in m. Then the return speed is faster than the cutting speed by

[PI 1989]

A single point cutting tool with 12° rake angle is used for orthogonal machining of a ductile material. The shear plane angle for the theoretically minimum possible shear strain to occur

[PI 1990]

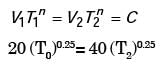

In a cutting test with 0.3 mm flank wear as tool failure criterion, a tool life of 10 min was obtained at a cutting velocity of 20 m/min. Taking tool life exponent as 0.25, the tool life in minutes at 40 m/min of cutting velocity will be

[PI 1993]

A workpiece of 2000 mm length and 300 mm width was machined by a planning operation with the feed set at 0.3 mm/stroke. If the machine tool executes 10 double strokes/min, the planning time for a single pass will be

[PI 1993]

In a single pass turning operation the cutting speed is the only variable based on the cutting time cost and the cutting edge cost. The tool life for minimum cost given that cost of 1 cutting edge is Rs. 5, operator wages including the machine tool cost is Rs. 75/hour and tool life equation is VT0.1 is 100

[PI 1995]

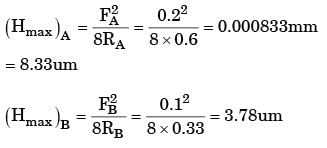

Two different tools A and B having nose radius of 0.6 mm and 0.33 mm respectively are used to machine C-45 steel employing feed rate of 0.2 mm/rev and 0.1 mm/rev respectively. The tool that gives better finish and the value of ideal surface roughness are

[PI 2002]

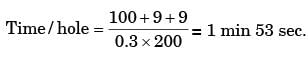

A 31.8 MM HSS drill is used to drill a hole in cast iron block 100 mm thick at cutting speed of 20 m/min and feed 0.3 mm/rev. If the over travel of drill is 4 mm and approach 9 mm, the time required to drill the hole is

[PI 2002]