Past Year Questions: Finishing Process - Mechanical Engineering MCQ

30 Questions MCQ Test - Past Year Questions: Finishing Process

Gear hobbing produces more accurate gears than milling because in hobbing

[ME 1989]

Teeth of internal spur gears can be accurately cut in a

[ME 1989]

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Minimum dimensional and form accuracy can be obtained in the cylinder bores of automobile engines if the bores are finished by

[ME 1989]

In small lot production for machining T-slots on machine tables, it is expected to use

[ME 1990]

Strong screw threads are produced by

[ME 2003]

Internal gear cutting operation can be performed by

[ME 2008]

Which pair of following statements is correct for orthogonal cutting using a single-point cutting tool?

P. Reduction in friction angle increases cutting force

Q. Reduction in friction angle decreases cutting force

R. Reduction in friction angle increases chip thickness

S. Reduction in friction angle decreases chip thickness

[ME 2014,Set-3]

In a machining operation, if the generatrix and directrix both are straight lines, the surface obtained is

[ME 2015,Set-3]

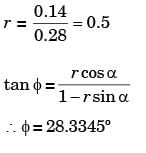

Orthogonal turning of a mild steel tube with a tool of rake angle 10° carried out at a feed of 0.14 mm/rev. If the thickness of the chip produced is 0.28 mm, the values of shear angle and shear strain will be respectively

[ME 2015,Set-3]

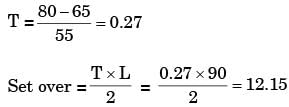

A shaft of length 90 mm has a tapered portion of length 55 mm. The diameter of the taper is 80 mm at one end and 65 mm at the other. If the taper is made by tailstock set over method, the taper angle and the set over respectively are

[ME 2015,Set-3]

The tool life equation for HSS tool is VT0.14f0.7d0.4 = Constant. The tool life (T) of 30 min is obtained using the following cutting conditions: V = 45 m/min, f = 0.35 mm, d = 2.0mm. If speed (V), feed (f) and depth of cut (d) are increased individually by 25%, the tool life (in min) is

[ME 2016,Set-1]

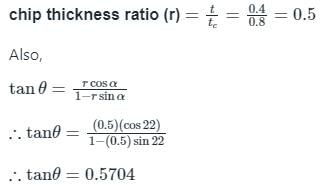

For an orthogonal cutting operation, tool material is HSS, rake angle is 22°, chip thickness is 0.8 mm, speed is 48 m/min and feed is 0.4 mm/rev. The shear plane angle (in degrees) is

[ME 2016,Set-3]

During the turning of a 20 mm diameter steel bar at a spindle speed of 400 rpm, a tool life of 20 minute is obtained. When the same bar is turned at 200 rpm, the tool life becomes 60 minute. Assume that Taylor's tool life equation is valid. When the bar is turned at 300 rpm, the tool life (in minute) is approximately ____ .

[ME 2017,Set-2]

Using the Taylor's tool life equation with exponent n = 0.5, if the cutting speed is reduced by 50%, the ratio of new tool life to original tool life is

[ME 2018,Set-1]

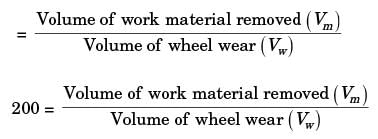

A grinding ratio of 200 implies that the

[ME 2018,Set-1]

In turning operation the surface finish can be improved by decreasing

[PI 1989]

Reamer is designed to have even number of flutes to

[PI 1990]

The teeth of both external and internal spur gears can be cut of

[PI 1991]

A blind hole is better tapped with a tap having

[PI 1992]

In metal cutting with a carbide tool, at the maximum recommended speed, the largest % of heat generated goes to be

[PI 1992]

Assertion (A): Grinding needs higher specific cutting energy than milling.

Reason (R): Milling cutter material is harder than abrasive grains.

[PI 1993]

In whitworth quick return mechanism (used in shapers) the velocity of the ram is maximum at

[PI 2001]

Which one of the following is not a synthetic abrasive material?

[PI 2003]

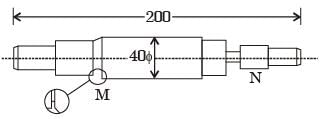

The drawing shows a machined shaft. The purpose of providing rounded grooves at M and N is to

[PI 2003]

The flanks of teeth of rack-type gear cutter used for cutting involute gear profiles are

The purpose of helical grooves in a twist drill is to

1. Improve the stiffness

2. Save a tool material

3. Provide space for chip removal

4. Provide rake angle for the cutting edge

Select the correct answer suing the codes given below:

[PI 2003]

The cutting portion of a drill is to be welded to its shank. The process best suited for this is

[PI 2004]

Consider the following statements with respect to the relief angle of cutting tool:

1. This affects the direction of chip flow.

2. This reduces excessive friction between the tool and workpiece

3. This affects tool life

4. This allows better access of coolant at the tool workpiece interface

Which of the statements given above are correct?

[PI 2004]

so less force is required for cutting.

so less force is required for cutting.