Past Year Questions: Metal Casting - Mechanical Engineering MCQ

30 Questions MCQ Test - Past Year Questions: Metal Casting

The contraction allowance provided on the pattern and core boxes compensates for the following type of contraction

[ME 1988]

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Two cubical castings of the same metal and size of 2 cm side and 4 cm side are moulded in green sand. If the smaller casting solidifies in 2 mins, the expected time of solidifications of large casting will be

[ME 1989]

The pressure at the in-gate will be maximum with the gating system

[ME 1990]

When there is no room temperature change, the total shrinkage allowance on a pattern is independent of

[ME 1991]

Converging passage is used for feeding the liquid molten metal into the mould to

[ME 1991]

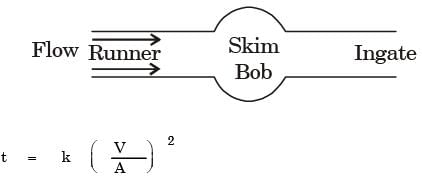

Light impurities in the molten metal are prevented from reaching the mould cavity by providing

[ME 1996]

Hardness of green sand mould increases with

[ME 2003]

With a solidification factor of 0.97 × 106 s/m2, the solidification time (in seconds) for a spherical casting of 200 mm diameter is

[ME 2003]

Gray cast iron blocks 200 x 100 x 10 mm are to be cast in sand moulds, Shrinkage allowance for pattern making is 1%. The ratio of the volume of pattern to that of the casting will be

[ME 2004]

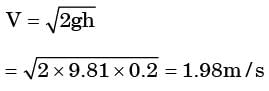

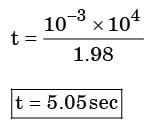

A mould has downsprue whose length is 20 cm and the cross sectional area at the base of the downsprue is 1 cm2. The downsprue feeds a horizontal runner leading into the mould cavity of volume 1000 cm3. The time required to fill the mould cavity will be

[ME 2006]

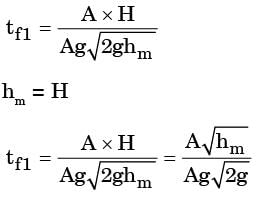

In a sand casting operation, the total liquid head is maintained constant such that it is equal to the mould height. The time taken to fill the mould with a top gate is tA. If the same mould is filled with a bottom gate, then the time taken is tB. Ignore the time required to fill the runner and frictional effects, Assume Atmospheric pressure at the top molten metal surfaces. The relation between tA and tB is

[ME 2006]

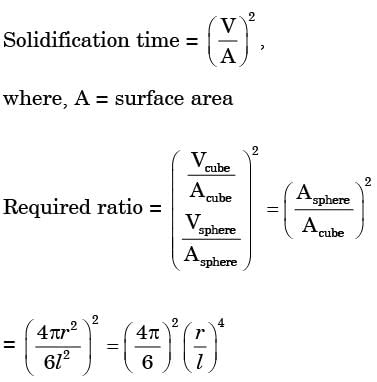

Volume of a cube of side l and volume of a sphere of radius r are equal. Both the cube and the sphere are solid and of same material. They are being east. The ratio of the solidification time of the cube to the same of sphere is

[ME 2007]

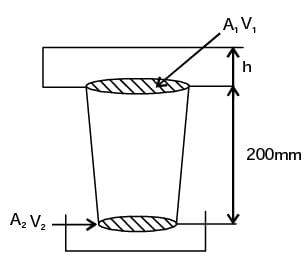

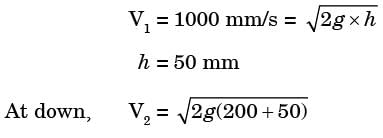

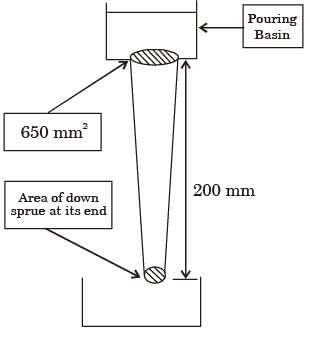

A 200 mm long down sprue has an area of crosssection of 650 mm2 where the pouring basin meets the down sprue (i.e. at the beginning of the down sprue). A constant head of molten metal is maintained by the pouring basin. The molten metal flow rate is 6.5 × 105 mm3/s. Considering the end of down sprue to be open to atmosphere and acceleration due to gravity of 104 mm/s2, the area of the down sprue in mm2 at its end (avoiding aspiration effect) should be

[ME 2007]

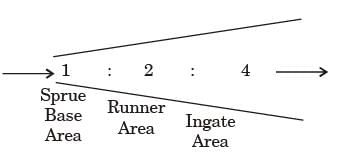

In a gating system, the ratio 1:2:4 represents

[ME 2010]

A cubic casting of 50 mm side under goes volumetric solidification shrinkage and volumetric solid contraction of 4% and 6% respectively. No riser is used. Assume uniform cooling in all directions. The side of the cube after solidification and contraction is

[ME 2011]

A cube shaped casting solidifies in 5 min. The solidification time in min for a cube of the same material, which is 8 times heavier than the original casting, will be

[ME 2013]

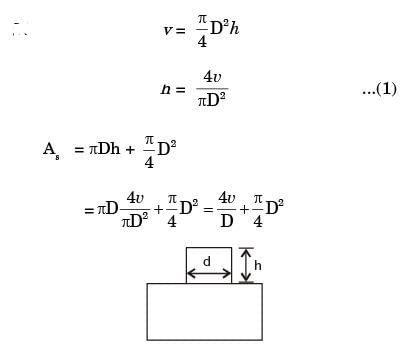

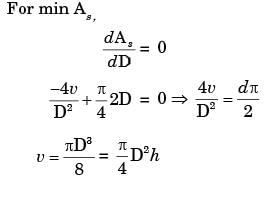

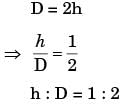

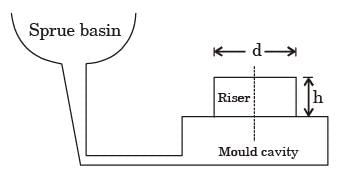

A cylindrical blind riser with diameter d and height h, is placed on the top of the mold cavity of a closed type sand mould as shown in the figure. If the riser is of constant volume, then the rate of solidification in the riser is the least when the ratio h : d is

[ME 2014,Set-3]

The solidification time of a casting is proportional to  where V is the volume of the casting and A is the total casting surface area losing heat. Two cubes of same material and size are cast using sand casting process. The top face of one of the cubes is completely insulated. The ratio of the solidification time for the cube with top face insulated to that of the other cube is

where V is the volume of the casting and A is the total casting surface area losing heat. Two cubes of same material and size are cast using sand casting process. The top face of one of the cubes is completely insulated. The ratio of the solidification time for the cube with top face insulated to that of the other cube is

[ME 2015,Set-1]

The part of a gating system which regulates the rate of pouring of molten metal is

[ME 2016,Set-1]

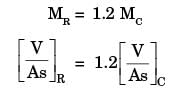

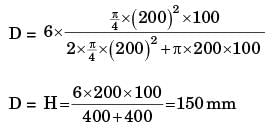

A cylindrical job with diameter of 200 mm and height of 100 mm is to be cast using modulus method of riser design. Assume that the bottom surface of cylindrical riser does not contribute as cooling surface. If the diameter of the riser is equal to its height, then the height of the riser (in mm) is

[ME 2016,Sat-1]

Equal amounts of a liquid metal at the same temperature are poured into three moulds made of steel, copper and aluminum. The shape of the cavity is a cylinder with 15 mm diameter. The size of the moulds are such that the outside temperature of the moulds do not increase appreciably beyond the atmospheric temperature during solidification. The sequence of solidification in the mould from the fastest to slowest is (Thermal conductivities of steel, copper and aluminum are 60.5, 401 and 237 W/mK, respectively. Specific heats of steel, copper and aluminum are 434, 385 and 903 J/ kgK, respectively. Densities of steel, copper and aluminum are 7854, 8933 and 2700 kg/m3, respectively.)

[ME 2016,Set-3]

The optimum pouring time for a casting depends on several factors. One important factor among them is

[PI 1991]

The primary function of a riser is to

[PI 1992]

Chaplets are placed between mould in order to

[PI 1992]

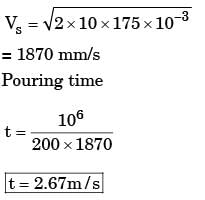

The height of the down sprue is 175 mm and its CS are at the base is 200 mm2. The CS area of the horizontal runner is also 200 mm2.Assuming no losses, indicate the correct choice for-the time (second) required to fill a mould cavity of volume 106mm3. (Use g = 10 m/s2)

[PI 2002]

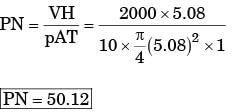

The permeability of moulding sand was determined using a standard AFS sample by passing 2000 cc of air at a gauge pressure of 10 g/cm2. If the time taken for the air to escape was 1 min, the permeability number is

[PI 2002]

Proper gating design in metal casting

P. Influences the freezing range of the melt

Q. Compensates the loss of fluidity of the melt

R. Facilitates top feeding of the melt S. Avoids misrun

[PI 2002]

A 10 mm thick steel bar is to be horizontally cast with two correctly top risers of adequate feeding capacity. Assuming end effect without chill, what should be the theoretical length of the bar?

[PI 2002]