Past Year Questions: Nonconventional Machining (ECM, EDM, ASM, USM) (Part - 2) - Mechanical Engineering MCQ

17 Questions MCQ Test - Past Year Questions: Nonconventional Machining (ECM, EDM, ASM, USM) (Part - 2)

In ECM, the metal removal rate is directly proportional to

[1991]

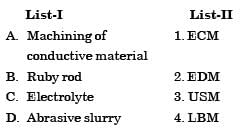

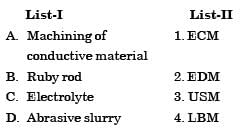

Match List-I (Material) with List-II (Machining) and select the correct answer using the code given below the lists;

A B C D

[2004]

A B C D

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

As sertion (A): In electr on beam weld ing process, vacuum is an essential process parameter.Reason (R): Vacuum provides a highly efficient shield on weld zone.

[2005]

Mechanism of material removal process R Abrasive grain throwing and hammering Q.Erosion due to vaporization R. Chipping and erosion S. Melting and partial vaporization T.Electrolysis

1. ECM

2. USM

3. PAM

4. EDM

5. AJM

P Q R S T

[2005]

Match Li st- I ( Machining processes) w i th List-II (Operating Media) and select the correct answer using the codes given below the lists:

List-I

A. Abrasive jet machining

B. Electron beam machining

C. Electrochemical machining

D. Electro-discharge machining

List-II

1. Dielectric

2. Electrolyte

3. Abrasive slurry

4. Vacuum

5. Air

A B C D

[2005]

Match the following

Group-I

P. Permaloy

Q. Dielectric

R. Accumulator

S. Anodic erosion

Group-II

1. EDM

2. USM

3. De-ionized water

4. Water jet machining

P Q R S

[2006]

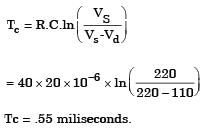

The time for one cycle, in milliseconds, is

[2006]

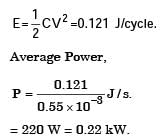

Average power input (in kW) is

[2006]

Which one of the following process conditions leads to higher MRR in ECM?

[2007]

In an AJM process, if Q = flow rate of abrasives and d = mean diameter of the abrasives, then MRR is proportional to

[2007]

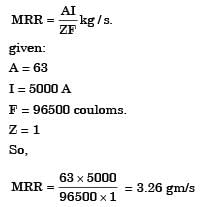

In a electrochemical machining ( E C M ) operation, a square hole of dimensions 5 mm × mm is drilled in a block of copper. The current used is 5000 A. Atomic weight of copper is 63 and valence of dissolution is 1. Faradays constant is 96500 coulomb. The material removal rate (g/s) is

[2008]

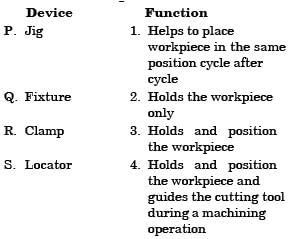

Match the following:

[2009]

A titanium sheet of 5.0 mm thickness is cut by wire cut EDM process using a wire of 1.0 mm diameter. A uniform spark gap of 0.5 mm on both sides of the wire is maintained during cutting operation. If the feed rate of the wire into the sheet is 20 mm/min, the material removal rate (in mm3/min) will be

[2009]

Ultrasonic machines used in material removal process, requires ultrasonic transducers. The transducers work on different working principles.One of the working principles of such ultrasonic transducers is based on

[1010]

Keeping all other parameters unchanged, the tool wear in electrical discharge machining (EDM) would be less if the tool material has

[2010]

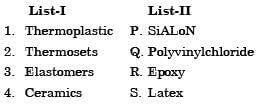

Match List-I (Type of material) with List-II (Name of material) and select the correct answer using the codes given below the lists;

P Q R S

[2011]

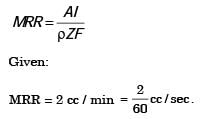

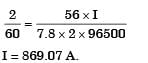

While removing material from iron (atomic weight = 56, valency = 2 and density = 7.8 g/cc by electrochemical machining, a metal removal rate of 2 cc/min is desired. The current (in A) required for achieving this material removal rate is

[2011]