Past Year Questions: Nonconventional Machining (ECM, EDM, ASM, USM) - Mechanical Engineering MCQ

30 Questions MCQ Test - Past Year Questions: Nonconventional Machining (ECM, EDM, ASM, USM)

In ECM, the material removal rate will be higher for metal with

[1989]

In USM the metal removal rate would ... with increasing mean grain diameter of the abrasive material

[1992]

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

The two main criteria for s electing the electrolyte in ECM is that the electrolyte should

[1992]

In ultrasonic machining process, the material removal rate will be higher for material with

[1993]

Selection of electrolyte for ECM is as follows

[1997]

Inter electrode gap in ECG is controlled by

[1997]

In EDM, the tool is made of

[1999]

Choose the correct statement

[ME 1999 : 1 Mark]

Deep hole drilling of small diameter, say 0.2 mm is done with EDM by selecting the tool material as

[2000]

In ECM the MRR is due to

[2001]

As tool and work are not in contact in EDM process

[2003]

The mechanism of material removal in EDM process is

[2004]

Typical machining ope ration s are to be performed on hard-to-machine materials by using the processes listed below. Choose the best set of Operation- Process combinations

Operation

P. Deburring (internal surface)

Q. Die sinking

R. Fine hole drilling in thin sheets

S. Tool sharpening Process

1. Plasma Arc Machining

2. Abrasive Flow Machining

3. Electric Discharge Machining

4. Ultrasonic Machining

5. Laser beam Machining

6. Electrochemical Grinding

[2004]

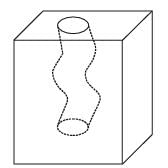

A zigzag cavity in a block of high strength alloy is to be finish machined. This can be carried out by using

[2005]

Arrange the processes in the increasing order of their maximum material removal rate.Electrochemical Machining (ECM) Ultrasonic Machining (USM) Electron Beam Machining (EBM) Laser Beam Machining (LBM) Electric Discharge Machining (EDM)

[2006]

In Electrodischarge Machining (EDM), if the thermal conductivity of tools is high and the specific heat of work piece is low, then the tool wear rate and material removal rate are expected to be respectively

[2007]

Match the most suitable manufacturing processes for the following parts, Parts P. Computer chip Q. Metal forming dies and moulds R. Turbine blade S. Glass Manufacturing Processes

1. Electrochemical Machining

2. Ultrasonic Machining

3. Electrodischarge Machining

4. Photochemical Machining

[2007]

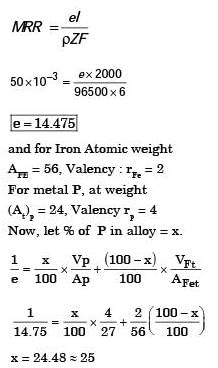

Are searcher conducts electrochemical machining (ECM) on a binary alloy (density 6000 kg/m3) of iron (atomic weight 56, valency 2) and metal P (atomic weight 24, valency 4). Faraday's constant = 96500 coulomb/mole. Volumetric material removal rate of the alloy is 50 mm3/s at a current of 2000 A. The percentage of the metal P in the alloy is closest to

[2008]

Electrochemical machining is performed to remove material from an iron surface of 20 mm × 20 mm under the following conditions: Inter electrode gap = 0.2 mm Supply voltage (DC) = 12 V Specific resistance of electrolyte = 2 ohm- cm Atomic weight of iron = 55.85 Valency of Iron = 2 Faraday's constant = 96540 Coulombs The material removal rate (in g/s) is

[2009]

In abrasive jet machining, as the distance between the nozzle tip and the work surface increases, the material removal rate

[2012]

Match the following non-traditional machining processes with the corresponding material removal mechanisms: Machining process P. Chemical machining Q. Electro-chemical machining R. Electro-discharge machining S. Ultrasonic machining Mechanism of material removal

1. Erosion

2. Corrosive reaction

3. lon displacement

4. Fusion and vaporization

[2011]

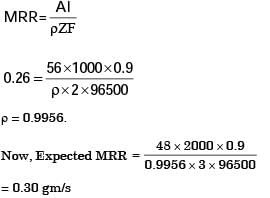

During the electrochemical machining (ECM) of iron (atomic weight = 56, valency = 2) at current of 1000 A with 90% current efficiency, the material removal rate was observed to be 0.26 cc/s. If Titanium (atomic weight = 48, valency = 3) is machined by the ECM process at the current of 2000 A with 90% current efficiency, the expected material removal rate in gm/s will be

[2013]

The following four unconventional machining processes are available in a shop floor. The most appropriate one to drill a hole of square cross section of 6 mm × 6 mm and 25 mm deep is

[2014]

The process utilizing mainly thermal energy for removing material is

[2014]

The principle of material removal in Electrochemical machining is

[2014]

The primary mechanism of material removal in electrochemical machining (ECM) is

[2015]

A resistance-capacitance relaxation circuit is used in an electrical discharge machining process. The discharge voltage is 100 V. At a spark cycle time of 25 ms, the average power input required is 1 kW. The capacitance (in mF) in the circuit is

[2015]

In a wire -cut EDM pr ocess the necessary conditions that have to be met for making a successful cut are that

[2016]

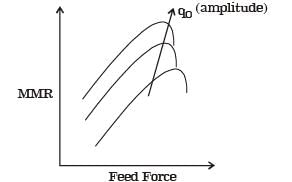

In an ultrasonic machining (USM) process, the material removal rate (MRR) is plotted as a function of the feed force of the USM tool. With increasing feed force, the MRR exhibits the following behavior:

[2016]

The non-traditional machining process that essentially requires vacuum is

[2016]

A.W.M.)

A.W.M.) Thermal conductivity of tool

Thermal conductivity of tool  material removal rate

material removal rate