Mechanical Engineering Exam > Mechanical Engineering Tests > SSC JE Mechanical Mock Test Series 2025 > Power Engineering - 2 - Mechanical Engineering MCQ

Power Engineering - 2 - Mechanical Engineering MCQ

Test Description

20 Questions MCQ Test SSC JE Mechanical Mock Test Series 2025 - Power Engineering - 2

Power Engineering - 2 for Mechanical Engineering 2024 is part of SSC JE Mechanical Mock Test Series 2025 preparation. The Power Engineering - 2 questions and answers have been

prepared according to the Mechanical Engineering exam syllabus.The Power Engineering - 2 MCQs are made for Mechanical Engineering 2024 Exam. Find important

definitions, questions, notes, meanings, examples, exercises, MCQs and online tests for Power Engineering - 2 below.

Solutions of Power Engineering - 2 questions in English are available as part of our SSC JE Mechanical Mock Test Series 2025 for Mechanical Engineering & Power Engineering - 2 solutions in

Hindi for SSC JE Mechanical Mock Test Series 2025 course. Download more important topics, notes, lectures and mock

test series for Mechanical Engineering Exam by signing up for free. Attempt Power Engineering - 2 | 20 questions in 12 minutes | Mock test for Mechanical Engineering preparation | Free important questions MCQ to study SSC JE Mechanical Mock Test Series 2025 for Mechanical Engineering Exam | Download free PDF with solutions

Detailed Solution for Power Engineering - 2 - Question 1

Power Engineering - 2 - Question 2

When inspection doors on the walls of boilers are opened, flame does not leap out because

Detailed Solution for Power Engineering - 2 - Question 2

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Detailed Solution for Power Engineering - 2 - Question 3

Detailed Solution for Power Engineering - 2 - Question 4

Detailed Solution for Power Engineering - 2 - Question 5

Detailed Solution for Power Engineering - 2 - Question 6

Detailed Solution for Power Engineering - 2 - Question 7

Detailed Solution for Power Engineering - 2 - Question 8

Detailed Solution for Power Engineering - 2 - Question 9

Power Engineering - 2 - Question 10

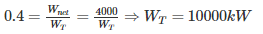

A gas turbine plant working on Joule cycle produces 4000 kW of power. If its work ratio is 40%, what is the power consumed by the compressor in (kW

Detailed Solution for Power Engineering - 2 - Question 10

Detailed Solution for Power Engineering - 2 - Question 11

Detailed Solution for Power Engineering - 2 - Question 12

Detailed Solution for Power Engineering - 2 - Question 13

Detailed Solution for Power Engineering - 2 - Question 14

Power Engineering - 2 - Question 15

Which of the following is the non-positive displacement compressor?

Detailed Solution for Power Engineering - 2 - Question 15

Detailed Solution for Power Engineering - 2 - Question 16

Detailed Solution for Power Engineering - 2 - Question 17

Detailed Solution for Power Engineering - 2 - Question 18

Detailed Solution for Power Engineering - 2 - Question 19

Power Engineering - 2 - Question 20

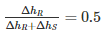

For minimum work input in a two-stage compression process the intermediate pressure is the

Detailed Solution for Power Engineering - 2 - Question 20

|

3 videos|1 docs|55 tests

|

Information about Power Engineering - 2 Page

In this test you can find the Exam questions for Power Engineering - 2 solved & explained in the simplest way possible.

Besides giving Questions and answers for Power Engineering - 2, EduRev gives you an ample number of Online tests for practice

|

3 videos|1 docs|55 tests

|

Download as PDF