Production Engineering - 3 - Mechanical Engineering MCQ

20 Questions MCQ Test SSC JE Mechanical Mock Test Series 2025 - Production Engineering - 3

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Cutting and forming operation can be performed in a single operation in a _______ die.

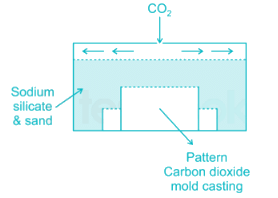

In carbon dioxide moulding process, the binder used is:

Enlarging an existing circular hole with a rotating single point tool is called:

In gas tungsten are welding process, the material coated on pure tungsten electron to enhance its current carrying capacity is

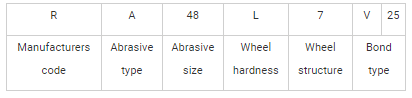

In a grinding wheel marked with R – A – 48 – L – 7 – V – 25, L & 7 refers to:

Which of the following has least percentage of carbon:

Which of the following processes come under the indirect compression technique?

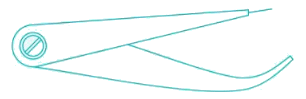

Which of the following can be used to scribe lines parallel to the edges of a part

The preferred option for holding an odd-shaped workpiece in a center lathe is

Which of the following is used as a dielectric medium in EDM?

‘Block’ used in AutoCAD (TB), holds an important role in productivity, Block is a(an)

|

3 videos|1 docs|55 tests

|

|

3 videos|1 docs|55 tests

|