Test: Casting Processes - 1 - Mechanical Engineering MCQ

10 Questions MCQ Test - Test: Casting Processes - 1

Consider the following materials:

1. Sand

2. Plaster and Ceramic

3. Metal

A mould can be made of

1. Sand

2. Plaster and Ceramic

3. Metal

A mould can be made of

The success of a casting process depends mainly on the following properties of the moulding sand:

1. Permeability

2. Strength.

3. Deformation

4. Flowability

5. Refractoriness

Which of the these are valid?

1. Permeability

2. Strength.

3. Deformation

4. Flowability

5. Refractoriness

Which of the these are valid?

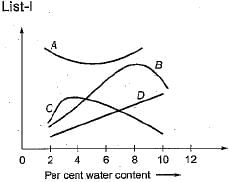

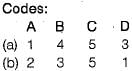

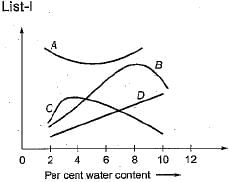

Match the List-I with List-ll:

List-ll

1. Deformation

2. Flowability

3. Permeability

4. Refractioness

5. Strength

List-ll

1. Deformation

2. Flowability

3. Permeability

4. Refractioness

5. Strength

The relative ability of the liquid metal to fill in the mould at a given temperature is knowns as

Which of the following gating ratio represents pressurised gating systems?

Which of the following methods increases turbulence in liquid metal flow in mould?

If metal is freezing against a flat mould wall and heat flow is normal to mould surface, then how the thickness (x) of solid metal deposited related with time (t)?

Three pieces being cast have the same volume but different shapes. One is sphere, one a cube, and the other a cylinder with a height equal to its diameter. Which piece will solidify the fastest?

Expendable moulds are destroyed to remove the casting when the process of solidification is over. Select the expendable moulds from the following lists:

1. Metal moulds

2. Sand moulds

3. Plaster moulds

Which of the following pattern-materials is used in precision casting?

1. Plaster of paris

2. Plastics

3. Anodized aluminium alloy

4. Frozen mercury