Test: Design Of Gears (Level - 2) - Mechanical Engineering MCQ

20 Questions MCQ Test - Test: Design Of Gears (Level - 2)

When two spur gears having involute profiles on their teeth engage, the line of action is tangential to the

Consider the following statements:

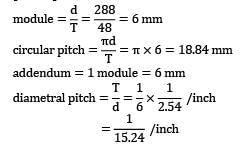

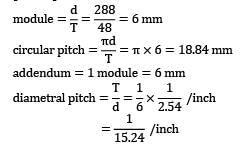

A pinion of  pressure angle and 48 involute teeth has a pitch circle diameter of 28.8 cm. It has

pressure angle and 48 involute teeth has a pitch circle diameter of 28.8 cm. It has

1. module of 6 mm

2. circular pitch of 18 mm

3. addendum of 6 mm

4. diametra! pitch of 11/113

Which of these statements are correct?

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

A spur gear transmits 10 kW at a pitch line velocity of 10m/s; driving gear has a diameter of 1.0 m. Find the tangential force between the driver and the follower, and the transmitted torque respectively.

Consider the following statements pertaining to the basic Lewis equation for the strength design of spur gear teeth

1. single pair of teeth participates in power transmission at any instant

2. the tooth is considered as a cantilever beam of uniform strength

3. loading on the teeth is static in nature

4. lewis equation takes into account the inaccuracies of the tooth profile

5. meshing teeth come in contact suddenly

Which of the statements given above are correct?

The dynamic load on a gear is due to

1). inaccuracies of tooth spacing

2). irregularities in tooth profile

3). deflection of the teeth under load

4). type of service (i.e. intermittent, one shift per day, continuous per day).

Which of the above statements are correct?

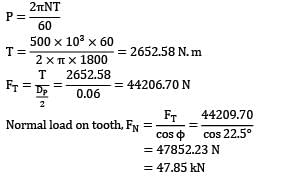

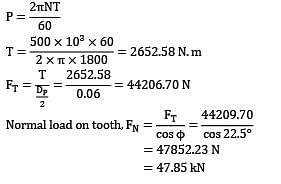

A pinion has 15 teeth and module of 8 mm. The gear ratio is 10 : 1 and the pressure angle is 22.5o. The pinion transmits 500 kW at 1800 rpm then normal load on the tooth will be __________ kN.

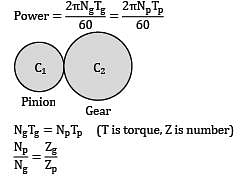

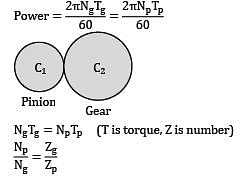

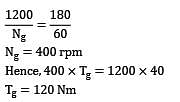

Two mating spur gear have 60 and 180 teeth respectively. The pinion rotates at 1200 rpm and transmits a torque of 40 Nm. The torque transmitted by gear is __________ Nm.

(A) 120

(B) 120

A spur gear has module of 3 mm, number of teeth 16, a face width of 36 mm and a pressure angle of 20o. It is transmitting a power of 3 kW at 20 rev/s. Taking a velocity factor of 1.5 and a form factor of 0.3, the stress in the gear tooth is __________ MPa.

A spur gear has a module of 4 mm, number of teeth 21, a face width 25 mm and a pressure angle of 20o. It is transmitting a power of 4 kW at 25 rev/s. Taking a velocity factor of 1.5 and a form factor of 0.3, the stress in the gear tooth is about

A spur gear has a module 3 mm, number of teeth 15 and a pressure angle 20o. It is transmitting torque of 30 Nm at 25 rev/s. The stress on gear tooth is 50 MPa. Taking a velocity factor of 1.4 and a form factor of 0.3. The face width of gear tooth is about

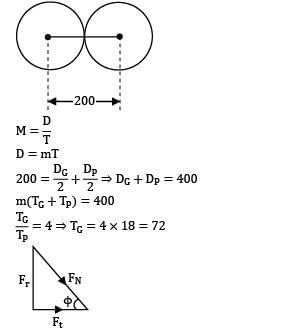

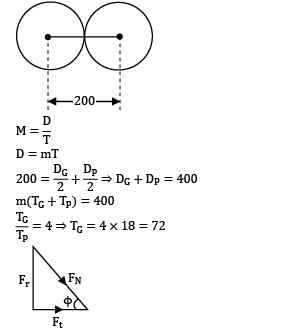

The following particulars refer to a spur gear drive, center distance = 200 mm; Ratio of number of teeth on gear to number of teeth on pinion![]() = 4 Power transmitted = 50 W; number of teeth on pinion = 18. Pinion speed (Np ) = 1440 rpm. Pressure angle (Φ) = 20o Permissible normal (total) Load = 160 N/mm of face width. The face width in mm is

= 4 Power transmitted = 50 W; number of teeth on pinion = 18. Pinion speed (Np ) = 1440 rpm. Pressure angle (Φ) = 20o Permissible normal (total) Load = 160 N/mm of face width. The face width in mm is

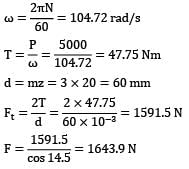

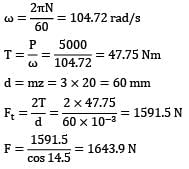

A spur pinion with module 3 mm and total number of teeth 20 transmits 5 kW of power. The gear rotates at 1000 rpm. The pressure angle of gear tooth is ![]() .

.

Assuming that only one pair of teeth is in contact, the total force (in Newton) exerted by a tooth of pinion on the tooth of a mating gear is __________.

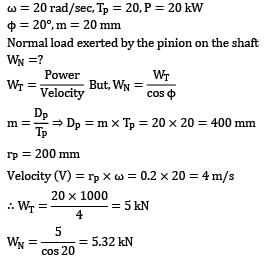

A spur pinion rotating at 20 rad/sec and having 20 teeth transmits 20 kW to a gear wheel. The pressure angle is 20o and module is 20 mm. The reaction exerted by the pinion at the center of the shaft is

A pair of spur pinion and gear made of cast steel (Sut = 110 MPa) and cast iron (Sut = 55 MPa) respectively. The pinion transmits 3274 N at 1250 rpm. The gear ratio is 3 : 1 and the teeth are full involute. Form factor y = ![]() .Width is 12 times module. The no. of teeth on pinion is 16, the module is

.Width is 12 times module. The no. of teeth on pinion is 16, the module is

A pinion has 15 teeth and module of 8 mm. The gear ratio is 10 : 1 and pressure angle is 22.5o. The pinion transmits the power 500 kW at 1800 rpm. What will be distance between the centers of gear and pinion and normal load on the tooth?

A simple gear train is designed with a pinion of 20 teeth and a gear wheel of 60 teeth. They have a pressure angle of 20o and a module of 2 mm. Both the pinion and gear have full depth involute tooth. Due to assembly constraints the center distance was made equal to 80.8 mm what will be the effective pressure angle?

A pair of straight teeth spur gears, having 20o involute full depth teeth is to transmit 12 kW at 300 rpm of the pinion. The speed ratio is 3 : 1. The allowable static stresses for gear of cast iron and pinion of steel are 60 MPa and 105 MPa respectively. Assume the following number of teeth of pinion = 16

Face width = 14 times module

Velocity factor = ![]()

Where V = pitch line velocity in m/s

![]() .

.

Tooth form factor y = 丌y

The module of the gear is __________

Assertion (A): The Lewis equation for design of gear tooth predicts the static load capacity of a cantilever beam of uniform strength.

Reason (R): According to law of gears interchangeability is possible only when gears have same pressure angle and same module.

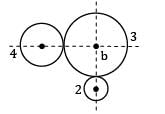

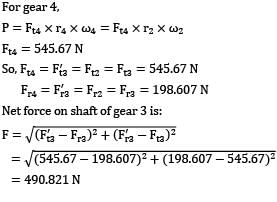

Pinion 2 in given figure has angular velocity 183.26 rad/s and transmit 2.5 kW to idle gear 3. The teeth cut on 20o the full depth system and their radius are R2 = 25 mm, R3 = 62.5 mm,R4 = 37.5 mm. What is the resultant reaction of gear 3 on its shaft?

(Where T stands for teeth)

A spur gear has module of mm, number of teeth 16, a face width of 36 mm and a pressure angle of 20o. It is transmitting power of 3kW at 20 rev/s. Taking velocity factor of 1.5 and a form factor of 0.3, the stress in the gear tooth in MPa is about

bybm)

bybm) b = 46.05 N/mm2

b = 46.05 N/mm2

mm

mm

R’ = 60.6 mm

R’ = 60.6 mm

2

2

n

n