Test: Refrigerant Compressors - Mechanical Engineering MCQ

10 Questions MCQ Test Thermodynamics - Test: Refrigerant Compressors

The purpose of refrigerant compressor is to

1. raise the pressure of the refrigerant.

2. raise the temperature of the refrigerant.

3. circulate the refrigerant through the refrigerating system.

4. improve the condenser performance.

Q. Which of the above are correct?

1. raise the pressure of the refrigerant.

2. raise the temperature of the refrigerant.

3. circulate the refrigerant through the refrigerating system.

4. improve the condenser performance.

The reciprocating refrigerant compressors are very much suitable for

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

The centrifugal compressors are generally used for refrigerants that require

The clearance volume in reciprocating refrigerant compressors the work done and the power required for compressing the refrigerant

The compressor of a domestic refrigerator has been noted to run for comparatively large durations. That indicates

The-pressure gauge on the discharge side of a refrigerant compressor reads too high. This could be due to

1. lack of cooling water

2. water temperature being high

3. dirty condenser surface

4. refrigerant temperature being too high

Q. Which of the above statements are valid?

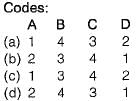

Match the List-I (Refrigeration equipment) with List-ll (Characteristic) the following:

List-I

A. Hermetically sealed compressor

B. Semi-hermetically sealed

C. Open type compressor

D. Expansion device

List-Il

1. Capillary tube

2. Both compressor and-motor enclosed in a shell or casing

3. Both compressor and motor enclosed in a shell or casing with a removable cover

4. Driving motor not enclosed in a shell or casing and connected to the shaft driving the compressor

The best capacity control method suitable for domestic refrigerant compressor is

The method of improving the volumetric efficiency include the following:

1. Providing clearance as large as possible.

2. Maintaining low pressure ratio.

3. Cooling during compression.

4. Reducing pressure drops at the valves by designing a light-weight valve mechanism, minimising valve overlaps and choosing suitable lubricating oils.

Q. Which of above statements are valid?

Consider the following capacity control method of centrifugal compressors:

1. Control of volume flow rate through a speed reduction gear

2. Variable inlet whirl vanes

3. Slide valve

Q. Which of the above is/are valid?

|

29 videos|65 docs|36 tests

|

|

29 videos|65 docs|36 tests

|