Power Engineering - 1 - Mechanical Engineering MCQ

20 Questions MCQ Test SSC JE Mechanical Mock Test Series 2025 - Power Engineering - 1

In a thermal power station, coal is used for the generation of electricity. How energy changes from one form to another before it is transformed into electrical energy?

For the same diameter and thickness of tube, a water tube boiler compared to a fire tube boiler has:

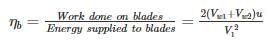

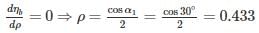

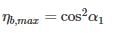

In a simple impulse turbine, the nozzle angle at the entrance is 30°. What will be the blade-speed ratio for maximum diagram efficiency?

The discharge through a converging - diverging nozzle reaches its maximum value when the flow becomes

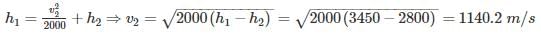

If the enthalpies at the entry and exit of a nozzle at 3450 kJ/kg and 2800 kJ/kg and the initial velocity is negligible, then the velocity at the exit is

Ratio of enthalpy drop in moving blades to the total enthalpy drop in the fixed and moving blades is called

Which one of the following groups of devices are used for part recovery of heat from the flue gases leaving the tube banks in a water tube boiler?

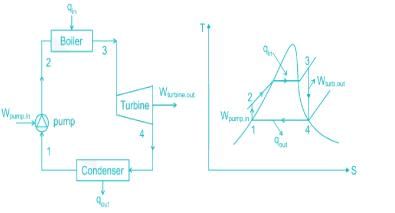

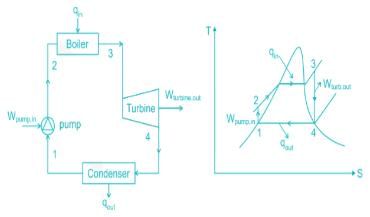

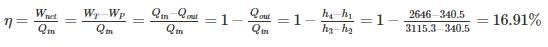

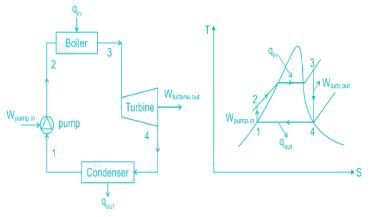

A simple Rankine cycle operates the Boiler at 3 MPa with an outlet temperature and enthalpy of 350°C and 3115.3 kJ/kg respectively and the condenser at 50 kPa. Assuming ideal operation and processes, what is the thermal efficiency of this cycle? Neglect the pump work. Assume exhaust from the turbine is dry saturated steam.

At 0.5 bar: hf = 340.5 kJ/kg, hg = 2646 kJ/kg

At 30 bar: hf = 1008 kJ/kg, hg = 2804 kJ/kg

In Rankine cycle, the work output from the turbine is given by

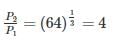

A three-stage reciprocating compressor has suction pressure of 1 bar delivery pressure of 64 bar. For minimum work of compression, the delivery pressure of first-stage is

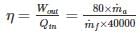

An open cycle constant pressure gas turbine uses a fuel of calorific value 40,000 kJ/kg, with the air-fuel ratio of 80 : 1 and develops a net output of 80 kJ/kg of air. The thermal efficiency of the cycle is

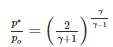

The mass flow through a convergent – divergent nozzle is maximum when the pressure at:

|

3 videos|1 docs|55 tests

|