Test: Building Materials- 3 - Civil Engineering (CE) MCQ

20 Questions MCQ Test Mock test series of SSC JE Civil Engineering 2025 - Test: Building Materials- 3

Which IS code is used for classification of timber for seasoning purposes?

Which one of the following is an ODD one as regards “requirements of good brick-earth”?

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

If aggregate size of 40-50 mm is to be tested for determining the proportion of elongated aggregates, the slot length of the gauge should be:

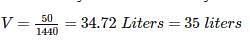

One bag of Portland cement, 50 kg in weight, would normally have a bulk volume of

The ratio of effective height to thickness of masonry walls should not be more than:

The average compressive strength of a burnt clay brick is less than 12.5 N/mm2. The allowable rating of efflorescence is:

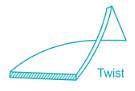

Shear strength of timber depends on which one of the following:

The peculiar curved swellings found on the body of a tree, are called:

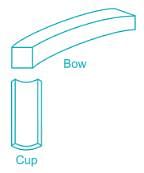

Consider the following statements with respect to defects of timber and identify the correct one:

As a construction material, plywood is preferred to thin planks of timber because of:

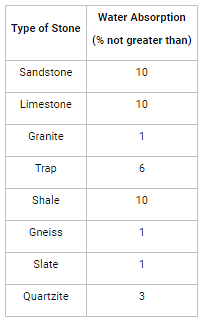

Which of the following stone has maximum % water absorption by volume?

Of the following, one which is not a type of Portland cement is

Various operations in the manufacturing of bricks are given below, of which one is not correct. The incorrect one is:

The process of taking out stones of various sizes from natural rocks is known as

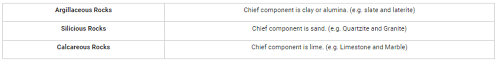

Rocks having lime as their major constituent are called:

The temperature at which the bricks are burnt in kiln varies from:

|

1 videos|1 docs|64 tests

|

|

1 videos|1 docs|64 tests

|

m

m