Test: Gears - 1 - Mechanical Engineering MCQ

10 Questions MCQ Test Design of Machine Elements - Test: Gears - 1

The gears are termed as medium velocity gears, if their peripheral velocity is

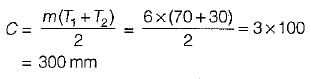

Two mating spur gears have 70 and 30 teeth respectively. Corresponding to module pitch 6 mm, the center to center distance between gears will be

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Which aspect is not true for a stub tooth when compared to full depth system?

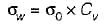

Allowable tooth stress for gear-tooth design depends upon the following parameters:

1. Type of gear material

2. Pitch line velocity

3. Beam strength of gear teeth

Which of the above is/are valid?

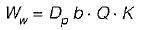

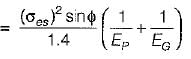

The tooth profiles must not have excessive contact stress as determined by the wear load to insure durability of a gear pair. This wear load is obtained using

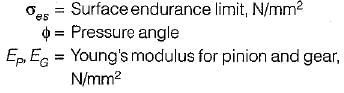

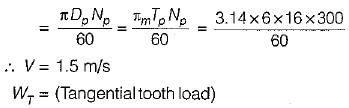

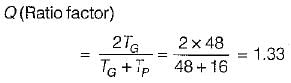

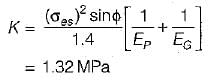

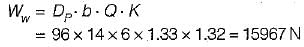

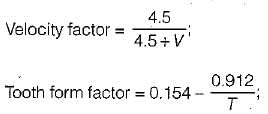

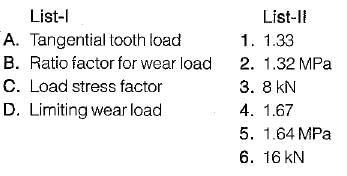

A pair of straight teeth spur gears with 6 mm module, having 20° involute full depth teeth is to transmit 12 kW at 300 rpm of the pinion. The speed ratio is 3:1. The allowable static stresses for gear of cast irion and pinion of steel are 60 MPa and 105 MPa respectively.

Assume the following:

Number of teeth on pinion = 16;

Face width = 14 m;

σes - 600 MPa; Ep = 200 GPa; EG = 100 GPa; Service factor, Cs = 1; sin20° = 0.342.

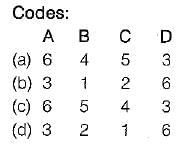

Based on these design data, match the followings:

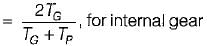

Cycloidal tooth profile of a cycloidal gear tooth is a combination of

|

49 videos|70 docs|77 tests

|

|

49 videos|70 docs|77 tests

|