Test: Joining Processes - 1 - Mechanical Engineering MCQ

10 Questions MCQ Test - Test: Joining Processes - 1

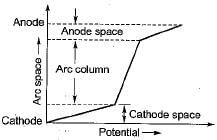

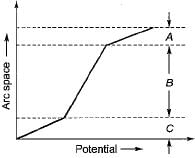

For given spacing, current and electrode material, the voltage drop across an arc is schematically shown in following figure

The region of arc column is represented by

The region of arc column is represented by

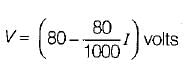

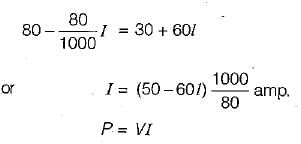

The voltage length characteristic of a direct current arc is given by

V= (30 + 60l) volts,

where l is the length of the arc in cm. The power source characteristic is approximated by a straight line with an open circuit voltage = 80 V and a short circuit current = 1000 amp. What is the optimum arc length?

V= (30 + 60l) volts,

where l is the length of the arc in cm. The power source characteristic is approximated by a straight line with an open circuit voltage = 80 V and a short circuit current = 1000 amp. What is the optimum arc length?

Consider the following statements pertaining to arc welding:

1. AC arc welding electrodes are coated with sodium silicate binders.

2. DC arc welding electrodes are coated with potassium silicate binders.

3. Potassium has a lower ionization potential as compared with sodium.

4. Reignition requires a voltage higher than the normal arc voltage.

Which of the above statements are valid?

1. AC arc welding electrodes are coated with sodium silicate binders.

2. DC arc welding electrodes are coated with potassium silicate binders.

3. Potassium has a lower ionization potential as compared with sodium.

4. Reignition requires a voltage higher than the normal arc voltage.

Which of the above statements are valid?

Adiabatic temperature in thermit welding is of the order of

The soldering process is carried out in the temperature range

The process of joining metal sheet by means of a fusible alloy or metal applied in the molten state is called

An alloy of copper, zinc and silver often used in fabrication work is called

The process of joining metallic pieces by introducing non-ferrous alloys in the liquid state between the metallic piece and allowing to solidify is known as