Mechanical Engineering Exam > Mechanical Engineering Tests > Topicwise Question Bank for Mechanical Engineering > Test: Toothed Gearing - 1 - Mechanical Engineering MCQ

Test: Toothed Gearing - 1 - Mechanical Engineering MCQ

Test Description

10 Questions MCQ Test Topicwise Question Bank for Mechanical Engineering - Test: Toothed Gearing - 1

Test: Toothed Gearing - 1 for Mechanical Engineering 2024 is part of Topicwise Question Bank for Mechanical Engineering preparation. The Test: Toothed Gearing - 1 questions and answers have been

prepared according to the Mechanical Engineering exam syllabus.The Test: Toothed Gearing - 1 MCQs are made for Mechanical Engineering 2024 Exam. Find important

definitions, questions, notes, meanings, examples, exercises, MCQs and online tests for Test: Toothed Gearing - 1 below.

Solutions of Test: Toothed Gearing - 1 questions in English are available as part of our Topicwise Question Bank for Mechanical Engineering for Mechanical Engineering & Test: Toothed Gearing - 1 solutions in

Hindi for Topicwise Question Bank for Mechanical Engineering course. Download more important topics, notes, lectures and mock

test series for Mechanical Engineering Exam by signing up for free. Attempt Test: Toothed Gearing - 1 | 10 questions in 30 minutes | Mock test for Mechanical Engineering preparation | Free important questions MCQ to study Topicwise Question Bank for Mechanical Engineering for Mechanical Engineering Exam | Download free PDF with solutions

Test: Toothed Gearing - 1 - Question 1

For an involute gear, the ratio, pitch circle radius/ base circle radius is (φ is the pressure angle)

Detailed Solution for Test: Toothed Gearing - 1 - Question 1

Test: Toothed Gearing - 1 - Question 2

Th e tooth profile most commonly used in gear drive for power transmission is

Detailed Solution for Test: Toothed Gearing - 1 - Question 2

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Detailed Solution for Test: Toothed Gearing - 1 - Question 3

Detailed Solution for Test: Toothed Gearing - 1 - Question 4

Test: Toothed Gearing - 1 - Question 5

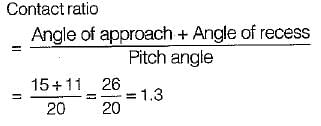

If angle of approach, pitch angle and angle of recess is given by 11°, 20° and 15° respectively, what is the contact ratio of gear?

Detailed Solution for Test: Toothed Gearing - 1 - Question 5

Detailed Solution for Test: Toothed Gearing - 1 - Question 6

Test: Toothed Gearing - 1 - Question 7

If a reduction ratio of about 50 is required in a gear drive then the most appropriate gearing would be

Detailed Solution for Test: Toothed Gearing - 1 - Question 7

Detailed Solution for Test: Toothed Gearing - 1 - Question 8

Detailed Solution for Test: Toothed Gearing - 1 - Question 9

Test: Toothed Gearing - 1 - Question 10

The motion transmitted between the teeth of two spur gears is generally

Detailed Solution for Test: Toothed Gearing - 1 - Question 10

|

45 videos|314 tests

|

Information about Test: Toothed Gearing - 1 Page

In this test you can find the Exam questions for Test: Toothed Gearing - 1 solved & explained in the simplest way possible.

Besides giving Questions and answers for Test: Toothed Gearing - 1, EduRev gives you an ample number of Online tests for practice

|

45 videos|314 tests

|

Download as PDF