Test: Toothed Gearing - 2 - Mechanical Engineering MCQ

10 Questions MCQ Test Topicwise Question Bank for Mechanical Engineering - Test: Toothed Gearing - 2

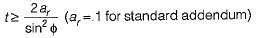

Minimum number of teeth for involute rack and pinion arrangement for pressure angle if 200 is

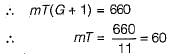

For a single reduction spur gear, the gear ratio is 10 to 1 and the center distance is 330 mm. The nearest standard module if no interference is to occur, will be

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

For helical gears, the helix angle generally ranges from

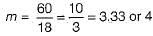

For helical gears, the circular pitch Pc, the normal pitch Pn and the helix angle a are related by the identity

Consider the following statements:

1. A stub both has working depth larger than that of a full depth tooth.

2. The path of contact for involute gears is an arc of a circle.

Which of these statements is/are correct?

The ends of gears are made slightly thinner (crowning). This is done

The maximum efficiency of worm and worm wheel system is

where φ is the friction angle

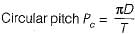

If D is pitch circle diameter and T is the number of teeth then its circular pitch is

|

45 videos|314 tests

|

|

45 videos|314 tests

|