Test: Metal Cutting & Tool Materials - 3 - Mechanical Engineering MCQ

30 Questions MCQ Test Topicwise Question Bank for Mechanical Engineering - Test: Metal Cutting & Tool Materials - 3

Which of the following forces are measured directly by strain gauges or force dynamometers during metal cutting?

1. Force exerted by the tool on the chip acting - normally to tool face.

2. Horizontal cutting force exerted by the tool on the workpiece.

3. Frictional resistance of the tool against the chip flow acting along the tool face.

4. Vertical force which helps in holding the tool in position.

1. Force exerted by the tool on the chip acting - normally to tool face.

2. Horizontal cutting force exerted by the tool on the workpiece.

3. Frictional resistance of the tool against the chip flow acting along the tool face.

4. Vertical force which helps in holding the tool in position.

The type of wear that occurs due to the cutting action of the particles in the cutting fluid is referred to as

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Consider the following tool materials:

1. High speed steel

2. High carbon steel

3. Cemented carbides

4. Ceramics

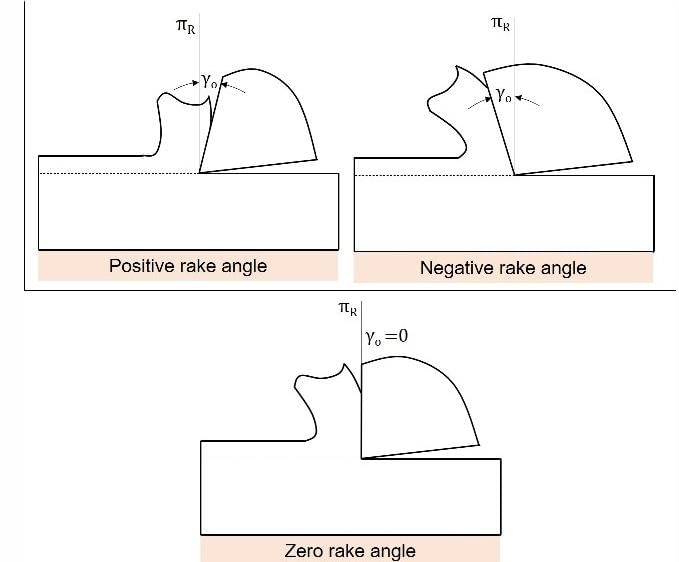

Q. Negative rake angle is provided for

1. High speed steel

2. High carbon steel

3. Cemented carbides

4. Ceramics

Q. Negative rake angle is provided for

The coefficient of friction in metal cutting varies between

The main source of heat generation in metal cutting is

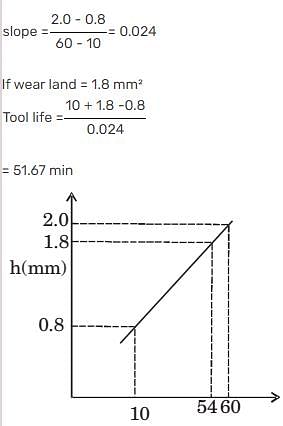

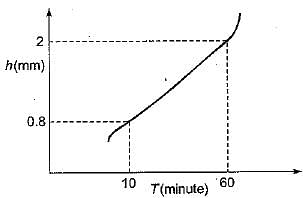

During machining, the wear land (h) has been plotted against machining time (T) as given in the following figure.

Q. For a critical wear land of 1.8 mm, the cutting tool life (in minute) is

Diamond cutting tools are not recommended for machining of ferrous metals due to

Inclination angle of a turning tool is measured on its

Inconel and Haste alloy require cutting tools that are

High tungsten content in a carbide tool will

Consider the following characteristics:

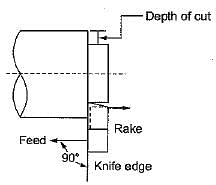

1. The cutting edge is normal to the cutting velocity.

2. The cutting forces occurs in two direction only.

3. The cutting edge is wider than the depth of cut.

The characteristics applicable to orthogonal cutting would include

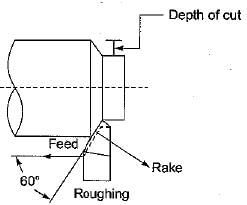

In oblique cutting of metals, the cutting edge of tool is

The portion of tool on which cutting edge is formed is known as

Tool signature in ASA system comprises of

Tool signature in ASA system, the nose radius is indicated in

Angle between the face and flank of the single point cutting tool is known as

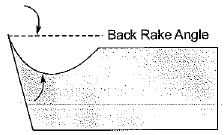

The angle between the face of the tool and the plane parallel to the base of the cutting tool is called

The angle on which the strength of the tool depends is

A blind hole is better tapped with a tap having

When machining a hard and brittle metal like cast iron, the type of chips produced is

Single point thread cutting tool should ideally have

The function of chip-breaker in a cutting tool is

In metal cutting operation, the approximate ratio of heat distributed among chip, tool and work in that order is

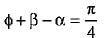

Which of the following is the correct relationship between the shear angle φ, friction angle β and cutting rake angle α given by Merchant analysis is

Which of the following relationship between shear angle φ, friction angle β and cutting rake angle α is known as lee and shatter analysis

|

45 videos|314 tests

|

|

45 videos|314 tests

|