Test: Casting Level - 1 - Mechanical Engineering MCQ

20 Questions MCQ Test Manufacturing Engineering - Test: Casting Level - 1

Small amount of carbonaceous material sprinkled on the inner surface of mould cavity is called:

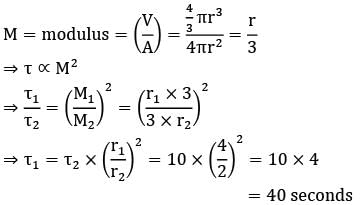

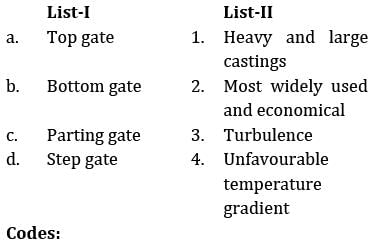

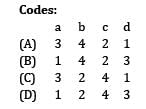

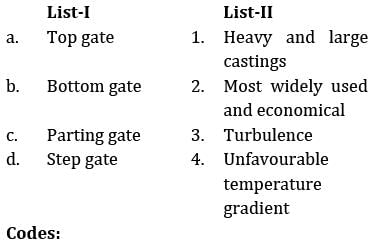

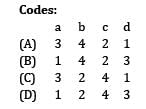

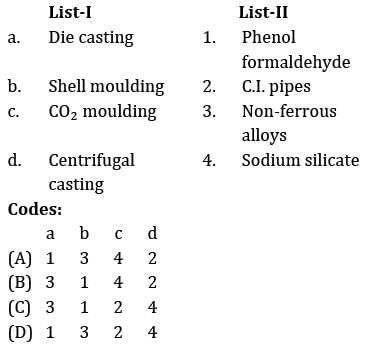

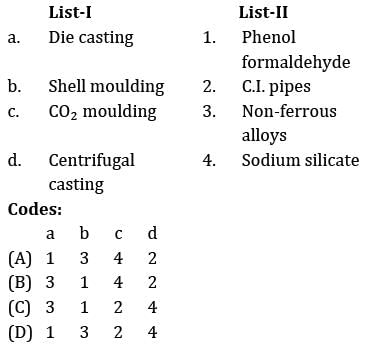

Match List-I with List-II and select the correct answer using the code given below the lists:

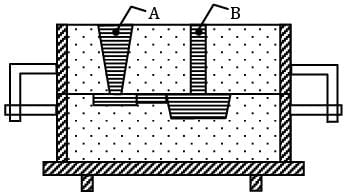

A sand casting mould assembly is shown in the above figure. The elements marked A and B are respectively

Which of the following are the requirements of an ideal gating system?

1. The molten metal should enter the mould cavity with as high velocity as possible.

2. It should facilitate complete filling of the mould cavity.

3. It should be able to prevent the absorption of air or gases from the surroundings in the molten metal while flowing through it.

Select the correct answer using the codes given below

The gating ratio for copper in gating system design refers to the ratio of areas of:

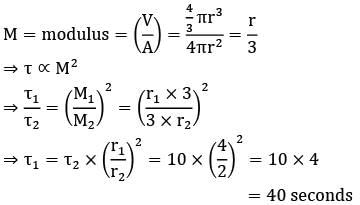

The relationship between total freezing time t, volume of the casting V and its surface area A, according to Chvorinov’s rule is:

Where ‘k’ is constant

A spherical drop of molten metal of radius 2 mm was found to solidify in 10 seconds. A similar drop of radius 4 mm would solidify in:

The ratio of surface area to volume for a unit volume of riser is minimum in case of:

When an alloy solidifies over a range of temperature, the resulting casting structure is:

Directional solidification in castings can be improved by using:

Consider the following advantages of shell mould casting:

1. Close dimensional tolerance

2. Good surface finish

3. Low cost

4. Easier

Which of these are correct?

Consider the following ingredients used in moulding:

1. Dry silica sand

2. Clay

3. Phenol formaldehyde

4. Sodium silicate Those used for shell mould casting include

Light and intricate parts with close dimensional tolerances of the order of  0.005 mm are produced by:

0.005 mm are produced by:

(A) investment casting

(B) die casting

(C) centrifugal casting

(D) shell mould casting

Which one of the following processes produces a casting when pressure forces the molten metal into the mould cavity?

Which of the following are the most likely characteristics in centrifugal casting?

Match List-I (Process) with List-II (Products/materials) and select the correct answer using the codes given below the lists:

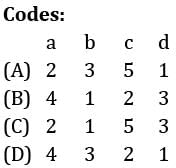

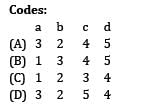

Match List-I (Name of the process) with List-II (Advantage) and select the correct answer using the codes given below the lists:

List-I

(Name of the process)

a. Sand casting

b. Ceramic mold casting

c. Die casting

d. Centrifugal casting

List-II

(Advantage)

1. Large cylindrical parts with good quality

2. Excellent dimensional accuracy and surface finish

3. Intricate shapes and close tolerance parts

4. Almost any metal can be casted and there is no limit to size, shape and weight

5. Good dimensional accuracy, finish and low porosity

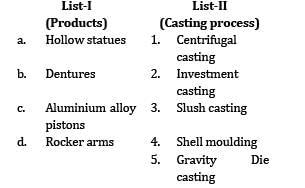

Match List-I (Products) with List-II (Casting process) and select the correct answer using the codes given below the lists:

|

56 videos|80 docs|29 tests

|

causes turbulence due to high head and velocity

causes turbulence due to high head and velocity unfavourable temperature gradient

unfavourable temperature gradient most widely used and economical

most widely used and economical multiple gates are used for heavy and large castings

multiple gates are used for heavy and large castings