Test: Forming Processes - 3 - Mechanical Engineering MCQ

30 Questions MCQ Test Topicwise Question Bank for Mechanical Engineering - Test: Forming Processes - 3

In wire drawing process, the bright shining surface on the wire is obtained if

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Tandem drawing of wires and tubes is necessary because

Match the List-l (Processes) with List-lI (Production of parts):

List-l

A. Rolling

B. Forging

C. Extrusion

D. Drawing

List-lI

1. Discrete parts

2. Rod and wire

3. Wide variety of shapes with thin walls

4. Flat plates and sheets

5. Solid and hollow parts

Codes:

A B C D

(a) 2 5 3 4

(b) 1 2 5 4

(c) 4 1 3 2

(d) 4 1 5 2

The reduction in sheet-metal drawing is defined as

where,

D = Blank diameter

d = Punch diameter

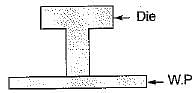

Match the List-I (Extrusion processes) with List-lI (Related description):

List-I

A. Direct extrusion

B. Indirect extrusion

C. Hydrostatic extrusion

D. Tube extrusion

List-Il

1. Mandrel

2. No friction

3. Stationary die

4. Moving die

Codes:

A B C D

(a) 4 2 3 1

(b) 3 2 4 1

(c) 3 4 2 1

(d) 3 4 1 2

Which one of the following is an advantage of forging

Which one of the following processes is adopted for manufacturing of steel balls for ball bearing?

Which one of the following metal forming processes in not a high energy forming processes?

A forging method for reducing the diameter of a bar and in the process making it longer is termed as

Which of the following manufacturing process will produce strongest component?

Which of the following metals is, best suitable for extrusion either hot or cold?

What does hydrostatic pressure in extrusion process improve?

In the metal extrusion process, when the.die angle increases, the required extrusion force

Which metal forming process is used for manufacturing of long steel wire?

Blanking and piercing operation can be performed simultaneously in

In piercing operation shear and clearance is provided on

A sheet of metal is being cut along its length in a straight line such a cutting operation is called

|

45 videos|314 tests

|

|

45 videos|314 tests

|