Test: APP & MRP Level - 2 - Mechanical Engineering MCQ

10 Questions MCQ Test Industrial Engineering - Test: APP & MRP Level - 2

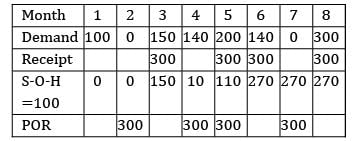

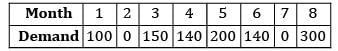

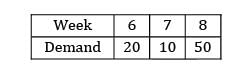

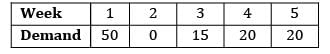

The master production schedule to manufacture a product is given below:

If the company follows Wilson’s model to place an order. The EOQ is given as 300, the stock-on-hand is 100, lead time is 1 month. Find the minimum number of orders required to fulfill the demand arise up to month-8

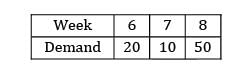

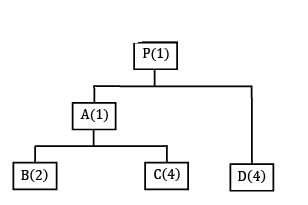

The product structure of product ‘P’ is shown in the figure below. The assembly of 2 units of ‘B’ and 4 units of ‘C’ to produce 1 unit of ‘A’ takes a week.

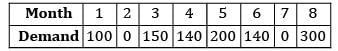

The ordering time of B, C and D are 2, 1 and 2 weeks. The master production schedule for product ‘P’ is as follows:-

The net requirement of ‘C’ if initial inventories of A, B, C and D are 10, 20, 15 and 40 is _____________

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

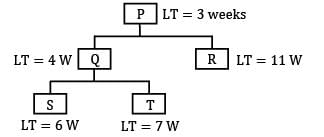

Item P is made from components Q and R. Item Q, in turn is made from S and T. The lead times for items P, Q, R, S and T are 3, 4, 11, 6 and 7 weeks respectively. The lead time(in weeks) needed to respond to a customer order for item P is

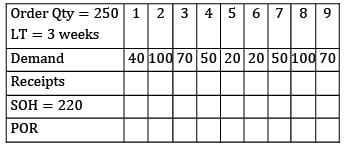

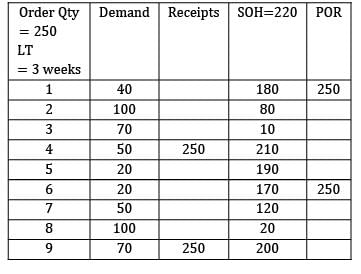

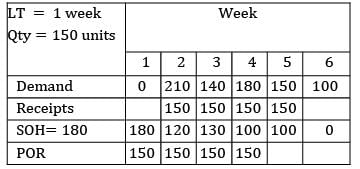

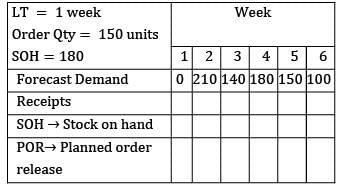

Consider the following MRP sheet

The inventory at the end of 5th week

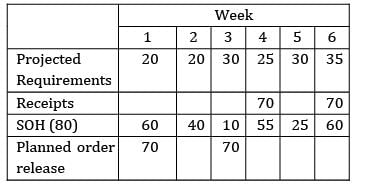

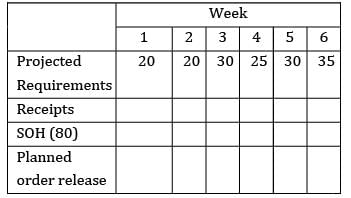

The material requirement planning for an item is shown in the table below: The ordering quantity is 80 units. The 2nd planned order release happens in the week of _______________

(Assume LT = 3 weeks)

A company contains two alternative methods for manufacturing a product. The estimated time and cost for both are given below

The number of units up to which milling is justified economically is

The plant has a capacity of producing 50,000 units per year. The annual fixed cost is Rs. 80,000. The variable cost per unit is Rs.18. The price of the product is Rs. 20 per unit. Then the breakeven point in terms of the capacity of the plant is

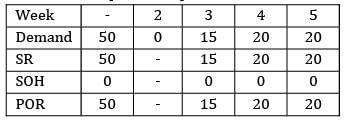

Find the total cost using Lot for Lot technique LT = 0, CO = Rs. 100/order, CC = Rs. 1/unit/week

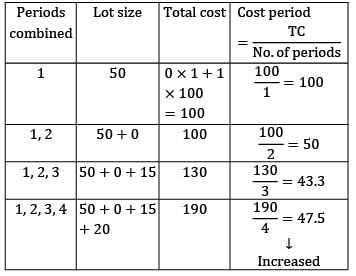

Find the total cost using minimum cost period technique.

LT = 0, CO = Rs. 100/order, CC = Rs. 1/unit/week

![]()

|

30 videos|40 docs|30 tests

|

|

30 videos|40 docs|30 tests

|