Production Engineering - 1 - Mechanical Engineering MCQ

20 Questions MCQ Test SSC JE Mechanical Mock Test Series 2025 - Production Engineering - 1

The main objective of ‘shot peening’ is to improve which property of metal parts

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Cold shut is a forging defect caused by which of the following reason?

For the same material, powder metallurgy process is superior to casting for

According to Indian standard specifications 50H7g6 means that:

1. Actual size is 50 mm

2. Tolerance grade for hole is 7

3. Tolerance grade for shaft is 6

Which of the statements are correct?

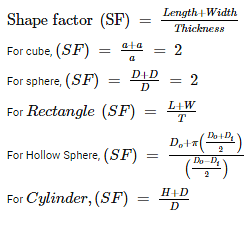

The shape factor for a spherical casting of diameter 20 cm is _________.

Assume that the two 2 mm thick steel sheets are being sport welded at a current of 5500 A and current - flow time t = 0.15s. Using electrodes 6 mm in diameter, estimate the amount of heat generated in resistance spot welding. (Take RC = 250 μΩ)

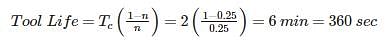

If the Taylor’s tool life exponent n is 0.25 and the tool changing time is 2 min, the tool life (in seconds) for maximum production rate is

A tool used in cutting an external thread is called a:

Which of the following surface hardening processes needs not quenching?

In a single pass rolling operation, if the coefficient of friction is doubled keeping other parameters same, the percentage change in draft will be _______ %

How many elements are present in tool signature of a single point cutting tool used for turning operation?

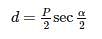

The best size wire (in mm) for measuring effective diameter of a metric thread (included angle is 60°) of 30 mm diameter and 3 mm pitch using two wire method is _______

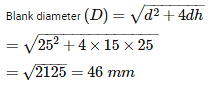

For obtaining a cup of diameter 25 mm and height 15 mm by drawing, the size of the round blank should be approximately

|

3 videos|1 docs|55 tests

|

|

3 videos|1 docs|55 tests

|