Bar Coding & RFID - Technology Structure, Logistics Management | Logistics Management - B Com PDF Download

Barcodes

A barcode is a visible series of bars (lines) or other shapes (1 or 2 dimensional) on paper that represent a set of data that, when scanned, is converted into a numeric code for further processing. A sensor and light is used to read barcode data.

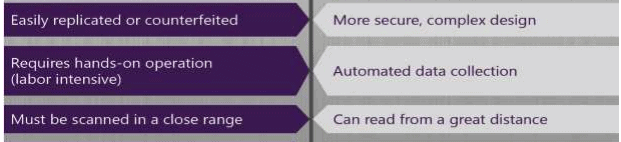

Because barcodes are printed on paper, they are smaller and lighter than RFID tags, but they are also more susceptible to counterfeiting, not to mention rips and other damage that may make them unreadable.

On the upside, barcodes tend to be less expensive and arguably have better accuracy. However, it is more labor intensive to use barcode technology – they require hands-on operation, the barcode must be in a scanner’s line of sight and only one tag can be read at a time.

RFID

A radio frequency identification technology (RFID) tag affixes to, identifies and tracks an item using radio waves. They have a more secure, complex design and have read/write capabilities, meaning large amounts of data can be programmed into the tag. They are used for automated data collection – tens, hundreds and even thousands can be read per second, and they can be read from a great distance and even when hidden (not in line of sight). Unlike paper barcodes, RFID tags are protected by a plastic cover, making them more durable and reusable.

RFID tags are vulnerable to reader or tag collision (i.e. a single tag tries to respond to two reader signals and is unable to respond to either or multiple tags in an area respond to a single reader simultaneously and therefore cannot process.) They are also more expensive.

RFID and barcodes both automate the data collection process and have advantages and disadvantages. Use our comparison infographic to weigh the differences and determine which technology better suits your application.

|

34 videos|29 docs|10 tests

|

FAQs on Bar Coding & RFID - Technology Structure, Logistics Management - Logistics Management - B Com

| 1. What is barcoding technology? |  |

| 2. How does barcoding technology work? |  |

| 3. What is RFID technology? |  |

| 4. How does RFID technology work? |  |

| 5. What are the advantages of using barcoding and RFID technologies in logistics management? |  |

|

Explore Courses for B Com exam

|

|