Ignition, Engine Friction, Lubrication & Cooling | Mechanical Engineering SSC JE (Technical) PDF Download

IGNITION, ENGINE FRICTION, LUBRICATION AND COOLING

The ignition should add sufficient energy for starting and sustaining burning of the fuel till combustion occurs.

TYPE OF IGNITION SYSTEM

Battery Ignition System

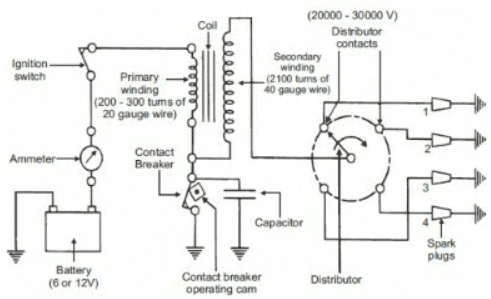

There are two circuits in this system. Primary circuit contains ignition switch, resistance unit, primary winding (100-200 turns), battery (6V - 12 V), secondary circuit includes secondary winding (2000 turns), distribution rotor, spark plug. After sudden opening of ignition switch in primary circuit, magnetic field across secondary winding collapse so generate high voltage which create spark in spark plug.

Magneto Ignition System

It is different from battery ignition system in the sense that current in the primary circuit is created by rotation of magnet by the engine. It has starting difficulty but is the best for high speed like in racing cars, aircraft engines.

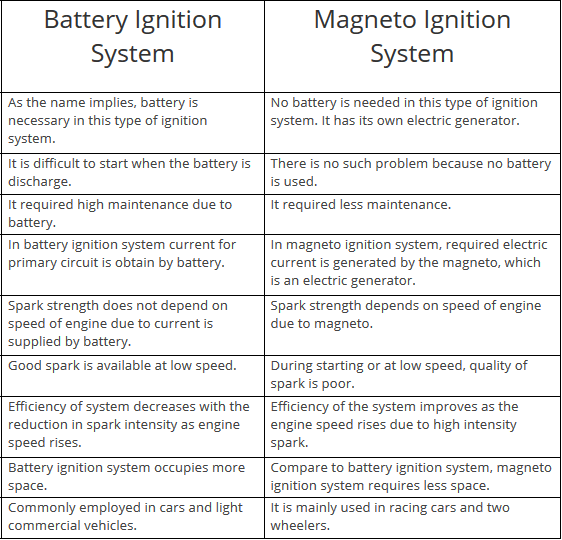

Comparison between Battery Ignition system and Magneto Ignition System

FIRING ORDER

It is used to reduce engine vibration, improves engine cooling and decrease in back pressure. For four cylinder engine Firing order : 1-3-4-2 For six Cylinder engines Firing order : 1-5-3-6-2-4

ENGINE FRICTION AND LUBRICATION

Friction power (f.p.) = i.p. – b.p. Methods to Determine Friction power from i.p. and b.p. measurement I.P. can be measured by indicator diagram and b.p by dynamometer so f.p = i.p. – b.p. It is very difficult to obtain accurate indicator diagram

Morse Test

In this method, individual cylinders are successively cut off and b.p. is determined. i.p of n cylinders and n–1 cylinders working (since f.p remains same for engine running with same speed). This method sis applicable only for multi cylinder engines.

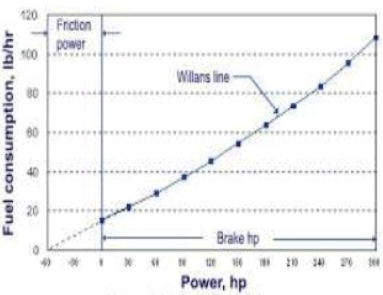

Willan's Line Method

When gross fuel consumption (or fuel flow rate) is plotted against b.p. (or torque) and the line so obtained is extended backwards to zero fuel consumption. The negative intercept on b.p. gives the value of f.p.

This method is applicable only for diesel (CI) engines.

Motoring Method

In this method, engine is driven with external motor without fining it. The power consumed by the motor is f.p. of the engine. By successive stripping off the engine, friction in each part of the engine can be calculated.

Functions of Lubrication:

-Lubrication

-Cooling the surface

-Cleaning of bearing and piston rings.

-Sealing between piston ring and cylinder wall.

-Noise reduction

Properties of Good Lubricating oil

Consistent viscosity over a range of temperature (high viscosity index) Very low cloud and pour point High flash and fire point Good oxidation stability Low acidity, high oiliness

LUBRICATING SYSTEM

Mist Lubricating System

It is used for 2 stroke engine where lubricant is mixed with fuel. Heavy exhaust emission, lack of lubrication when throttle is closed are the disadvantage. Low cost is advantage of this system. Wet Sump Lubrication In this, bottom part of crankcase (sump) contains lubricating oil, which with connection rod or fuel pump splashes the lubricating oil on engine parts.

ENGINE COOLING

To prevent overheating of engine parts. To prevent excessive thermal stress which causes cracking in engine parts. To improve volumetric efficiency and power output of the engine

Overcooling may cause difficulty in starting of engine and sulphur product may cause corrosion in engine.

Types of cooling

Air cooling: It is mainly used for small engines like motorcycle. scooters.

Water cooling: Antifreeze solution like Kerosene, Glycerine are used with water. This cooling is of different types depending on method of circulation of water. Following are the methods of water cooling.

Properties of Good Lubricating oil: In this water is circulated due to density difference of water at different temperatures. Water becomes light on heating goes up and replaced by cold having more density

The main disadvantage of this system is cooling does not increase with engine speed as they are independent and no cooling at low speeds.

Forced Pump System: In this system, thermostat (Sensitive to temperature) is used to stop coolant flow to avoid overcooling and so corrosion. The main advantage is that engine warms up quickly after starting Pressurized water cooling Here more pressure is applied to increase boiling point of water and so increasing its

Evaporative cooling: This method of cooling utilize the high latent heat of vapourized of water to go away with water vapour and thus cooling the water.

|

6 videos|104 docs|59 tests

|

FAQs on Ignition, Engine Friction, Lubrication & Cooling - Mechanical Engineering SSC JE (Technical)

| 1. What is ignition in the context of mechanical engineering? |  |

| 2. How does engine friction affect the performance of a mechanical system? |  |

| 3. Why is lubrication important in mechanical engineering? |  |

| 4. What are the different types of cooling systems used in mechanical engineering? |  |

| 5. How can the cooling system be optimized in mechanical engineering applications? |  |