Class 8 History Notes - Weavers, Iron Smelters and Factory Owners

During British rule, textiles and iron/steel industries thrived, making Britain an industrial leader. India's colonization led to trade shifts; British goods flooded Indian markets, impacting local crafts and industries, a focus in this chapter

Indian Textiles and the World Market

Patola weave, mid-19th century Textile Production in 1750:

Patola weave, mid-19th century Textile Production in 1750: Before the British took control of India, Indian textiles were highly regarded and traded globally. European traders bought these textiles and sold them in Europe. They were known for their quality and colorful designs. Words like "muslin" and "calico" originated from the Indian textile trade. Indian weavers were skilled at making these fabrics, which were loved by people all over the world, including wealthy individuals like the Queen of England.

Worlds Tell Us Histories-

- European traders encountered fine Indian cotton through Arab merchants in Mosul, leading them to use the term "muslin" for all finely woven textiles.

- Upon the Portuguese arrival in Calicut, India, textiles taken back along with spices were named "calico" (from Calicut), becoming a general term for cotton fabrics.

- Other words in Western markets also highlight the popularity of Indian textiles.

- An order book from the English East India Company in 1730, requesting 589,000 cloth pieces, showcased 98 varieties of cotton and silk textiles known as "piece goods" in European trade.

- The order book included printed cotton fabrics like chintz, cossaes (or khassa), and bandanna.

- The term "chintz" originates from the Hindi word "chhint," representing cloth with small, colorful floral designs.

- From the 1680s, there was a growing fascination in England and Europe for printed Indian cotton textiles due to their beautiful floral patterns, fine texture, and affordability.

- Even wealthy people in England, including the Queen, wore clothing made from Indian fabric.

- "Bandanna" now signifies any brightly colored printed scarf worn around the neck or head.

Bandana Style

Bandana StyleIndian textiles in European markets

- In the early 18th century, English wool and silk producers protested against the popularity of Indian cotton textiles.

- The British government enacted the Calico Act in 1720, prohibiting the use of printed Indian cotton textiles (chintz) in England.

- English textile industries, still in their early stages, struggled to compete with Indian textiles.

- The Calico Act protected the emerging calico printing industry in England, where Indian designs were imitated and printed on local cloth.

- This competition spurred technological innovation in England, leading to inventions like the spinning jenny by John Kaye in 1764 and the steam engine by Richard Arkwright in 1786, revolutionizing textile production.

- Despite these innovations, Indian textiles continued dominating world trade till the late 18th century, generating enormous profits for European trading companies.

- The English East India Company, after gaining political power in Bengal, used local revenues instead of importing silver to purchase Indian goods, altering their trade practices.

Who were the weavers?

- Weavers were skilled artisans, often from specific communities known for weaving expertise, passing down skills through generations like the tanti weavers of Bengal or the julahas in north India.

- Spinning, mainly done by women using tools like charkha and takli, preceded weaving; dyeing was handled by the rangrez, while block printing was the domain of chhipigars.

- Handloom weaving and associated occupations were vital for many Indians, providing livelihoods for millions.

- However, the rise of British cotton industries affected Indian textile producers significantly: Indian textiles had to compete in global markets, facing high duties in Britain, eventually losing traditional markets in Africa, America, and Europe by the early 19th century.

- This shift led to thousands of Indian weavers losing jobs, especially in Bengal, as English cloth flooded Indian markets by the 1830s, rendering spinners and weavers unemployed.

- Despite this, handloom weaving persisted for specific textiles in demand, not replicable by machines, favored by the rich and middle classes.

- During the national movement, Mahatma Gandhi advocated for khadi, hand-spun, and hand-woven cloth, making it a symbol of nationalism.

- Many weavers turned to agricultural labor, some migrated to cities or abroad, while others found work in emerging cotton mills in Bombay, Ahmedabad, Sholapur, Nagpur, and Kanpur.

The decline of Indian textiles

The rise of cotton industries in Britain had a big impact on textile makers in India. First, Indian textiles had to compete with British ones in global markets. Second, high duties made it hard to sell in England.

Impact on Indian Weavers

By the 1800s, British cloth replaced Indian goods in many markets, leaving thousands of Indian weavers unemployed, especially in Bengal. Companies stopped buying Indian goods, hurting the weavers' income. Many pleaded to the government for help. Later, British cloth flooded Indian markets, leaving even spinners without jobs.

Survival of Handloom Weaving

Handloom weaving survived for specific cloths with intricate designs that machines couldn’t replicate. Also, British manufacturers didn’t produce some coarse cloths used by India's poor.

Response and New Centers of Weaving

Towns like Sholapur and Madurai became important for weaving. During the national movement, Gandhi urged people to boycott imported textiles, promoting hand-spun Khadi as a symbol of nationalism.

Impact on Weavers

Jobless weavers became laborers or migrated, some even going abroad. Some found work in new cotton mills in Indian cities like Mumbai, Ahmedabad, Sholapur, Nagpur, and Kanpur.

Cotton Mills Come Up

- Early Cotton Mills in India

- The first cotton mill, a spinning mill, was established in Bombay in 1854.

- Bombay became a significant port for exporting raw cotton due to its proximity to the western Indian region where cotton was grown.

- The availability of raw materials made it convenient for the cotton textile mills to operate.

- Expansion and Ownership

- By 1900, more than 84 mills were functioning in Bombay.

- Parsi and Gujarati businessmen, involved in trade with China, were behind the establishment of several mills.

- Other cities like Ahmedabad and Kanpur also saw the emergence of mills during this time.

- Impact and Labor Demand

- The growth of cotton mills attracted labor from rural areas, drawing in thousands of peasants, artisans, and agricultural laborers to work in these mills.

- This migration led to an increased workforce in the cities.

- Challenges Faced

- In its early years, the Indian textile industry encountered difficulties competing with the inexpensive textiles imported from Britain.

- While many countries protected their industries by imposing heavy import duties, the colonial Indian government didn't extend such support to local industries.

- Boost During World War I

- The development of cotton factory production in India saw a significant rise during World War I.

- As textile imports from Britain reduced during the war, Indian factories were relied upon to produce cloth for military supplies.

The Sword of Tipu Sultan and Wootz steel

Tipu Sultan and Wootz Steel

- Tipu Sultan, a ruler in Mysore until 1799, had legendary swords made of a special steel called Wootz.

- These swords were known for their hard, sharp edge that could easily penetrate armor due to the unique high carbon steel.

- Wootz steel, prevalent in South India, produced swords with a distinct flowing water pattern from tiny carbon crystals in the iron.

- Wootz Steel Production

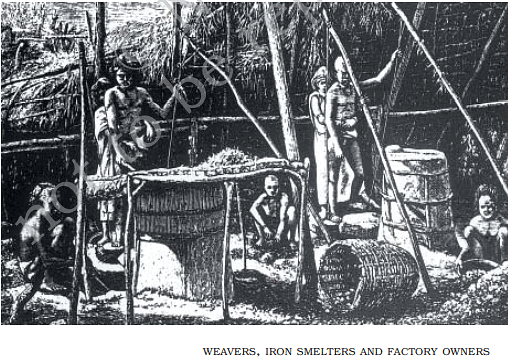

- Francis Buchanan observed the technique of making Wootz steel in Mysore using small clay pots filled with iron and charcoal in hundreds of smelting furnaces.

- These furnaces meticulously controlled temperatures to create steel ingots used not only in India but also in West and Central Asia for sword making.

- 'Wootz' comes from regional words meaning steel in Kannada, Telugu, Tamil, and Malayalam.

- European Interest and Decline

- European scientists like Michael Faraday were intrigued by Indian Wootz steel and studied its properties for years.

- However, by the mid-19th century, the knowledge of making Wootz steel in South India was lost.

- The decline was due to the British conquest of India, which led to the importation of iron and steel from England, displacing locally crafted iron and steel.

Abandoned Furnaces in Villages

By the late 19th century, the craft of iron smelting began declining. Villages saw a decrease in furnace use and iron production.

- Common Iron Smelting:

- Iron smelting was widespread in India till the late 19th century, especially in Bihar and Central India, where local ore was used to produce iron for tools and implements.

- Most smelters were made of clay and sun-dried bricks.

- Decline in Iron Smelting

- Reasons for decline

- New forest laws restricted access to wood for charcoal and iron ore, affecting smelters' ability to produce.

- Many resorted to illegal entry into forests but couldn't sustain this practice for long, leading some to abandon iron smelting.

- In areas with forest access, smelters faced high taxes for furnace use, reducing their income.

- The import of iron and steel from Britain lowered demand for locally produced iron, as Indian ironsmiths started using imported materials.

- Reasons for decline

- New Competition:

- By the early 20th century, Indian artisans producing iron and steel faced competition from new sources.

Iron and Steel Factories Come Up in India

- Search for Iron Ore:

- In 1904, American geologist Charles Weld and Dorabji Tata sought iron ore deposits in Chhattisgarh to establish a modern iron and steel plant in India.

- Jamsetji Tata planned to build a significant iron and steel industry but needed quality iron ore sources.

- They encountered the Agarias, who led them to Rajhara Hills, where they discovered fine-quality iron ore.

- Challenges and Discoveries:

- The Rajhara Hills lacked nearby water sources crucial for the factory, prompting further exploration.

- Later, the Agarias contributed to finding iron ore sources for the Bhilai Steel Plant.

- Ultimately, a suitable location with water near iron ore deposits was found along the Subarnarekha river, leading to the establishment of Jamshedpur and the Tata Iron and Steel Company (TISCO) in 1912.

- TISCO's Significance:

- During the late 19th century, India imported steel from Britain, particularly for railway expansion.

- Initially, British experts doubted India's capacity to produce quality steel.

- With the outbreak of World War I in 1914, British steel imports into India decreased as the demand for war supplies in Europe increased.

- TISCO supplied the Indian Railways with rails and produced war materials, gaining substantial government support.

- By 1919, the colonial government purchased 90% of TISCO's steel, making it the largest steel industry within the British empire.

- Impact on Industrial Expansion:

- Industrial growth in India occurred as British imports declined and the demand for Indian industrial goods rose, notably during and after World War I.

- The nationalist movement and the strengthening industrial class increased the demand for government protection, which the British government gradually conceded in the later stages of colonial rule.

|

69 videos|431 docs|46 tests

|

FAQs on Class 8 History Notes - Weavers, Iron Smelters and Factory Owners

| 1. What role did Indian textiles play in the world market during historical times? |  |

| 2. How did the Sword of Tipu Sultan reflect the craftsmanship of Indian metallurgy? |  |

| 3. What were the implications of abandoned furnaces in villages for the local economy? |  |

| 4. How did the establishment of iron and steel factories in India change the landscape of production? |  |

| 5. What was the relationship between weavers, iron smelters, and factory owners in the context of Indian industrialization? |  |