Mechanical Engineering Exam > Mechanical Engineering Notes > Solid Mechanics > Torsion of Circular Shafts

Torsion of Circular Shafts | Solid Mechanics - Mechanical Engineering PDF Download

Uniform Torsion

- Torsion of Shaft and Combined Stresses

Torsion means twisting a structural Member when it is loaded by a couple that Produces rotation about the longitudinal axis.

If τ be the intensity of shear stress, on any layer at a distance r from the centre of shaft, then

τl / r = T / J = Gθ / l

- Sign Convention

(i) Sign convention of torque can be explained by right hand thumb rule.

(ii) A positive torque is that in which there is tightening effect of nut on the bolt. From either side of the cross-section. If torque is applied in the direction of right hand fingers than right hand thumbs direction represents movement of the nut. TMD = Torsion moment diagram

TMD = Torsion moment diagram

T = Torque

Total angle of twist :

θ = Tl / GJ

Where, T = Torque,

J = Polar moment of inertia

G = Modulus of rigidity,

θ = Angle of twist

L = Length of shaft,

GJ = Torsional rigidity

GJ / l → Torsional stiffness;

l / GJ → Torsional flexibility

EA / l → Axial stiffness

l / EA → Axial flexibility - Moment of Inertia About polar Axis

(i) For solid circular shaft:

(ii) For hollow circular shaft:

- Power Transmitted in the Shaft

(i) Power transmitted by shaft:

P = (2πNT / 60000)kW

Where, N = Rotation per minute. - Compound Shaft

An improved type of compound coupling for connecting in series and parallel are given below

(i) Series connection: Series connection of compound shaft as shown in figure. Due to series connection the torque on shaft 1 will be equal to shaft 2 and the total angular deformation will be equal to the sum of deformation of 1st shaft and 2nd shaft. θ = θ1 + θ2

θ = θ1 + θ2

T = T1 + T2

Therefore,

θ = TL1 / G1J1 + TL2 / G2J2

Where,

θ1 = Angular deformation of 1st shaft

θ2 = Angular deformation of 2nd shaft

(ii) Parallel connection: Parallel connection of compound shaft as shown in figure. Due to parallel connection of compound shaft the total torque will be equal to the sum of torque of shaft 1 and torque of shaft 2 and the deflection will be same in both the shafts. θ1 = θ2

θ1 = θ2

T = T1 + T2

Therefore,

T1L / G1J1 = T2L / G2J2 - Strain energy (U) stored in shaft due to torsion

(i) G = Shear modulus

(ii) T = Torque

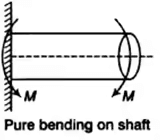

(iii) J = Moment of inertia about polar axis - Effect of Pure Bending on Shaft

The effect of pure bending on shaft can be defined by the relation for the shaft,

σ = 32M / πD3

Where, σ = Principal stress

D = Diameter of shaft

M = Bending moment - Effect of Pure Torsion on Shaft

It can be calculated by the formula, which are given below τmax = 16T/πD3

τmax = 16T/πD3

Where, τ = Torsion

D = Diameter of shaft - Combined effect of bending and torsion

(i) Principal stress

(i) Principal stress

(ii) Maximum shear stress

(iii) Equivalent bending moment

(iv) Equivalent torque

- Shear Stress Distribution

(i) Solid Circulation Section: (ii) Hollow Circulation Section

(ii) Hollow Circulation Section (iii) Composite Circular Section

(iii) Composite Circular Section (iv) Thin Tubular section: In view of small thickness-shear stress is assumed to be uniform.

(iv) Thin Tubular section: In view of small thickness-shear stress is assumed to be uniform.

The document Torsion of Circular Shafts | Solid Mechanics - Mechanical Engineering is a part of the Mechanical Engineering Course Solid Mechanics.

All you need of Mechanical Engineering at this link: Mechanical Engineering

|

33 videos|27 docs|29 tests

|

FAQs on Torsion of Circular Shafts - Solid Mechanics - Mechanical Engineering

| 1. What is torsion and how does it affect circular shafts? |  |

Ans. Torsion refers to the twisting of a circular shaft due to an applied torque or twisting moment. It causes shear stress to be distributed throughout the shaft, resulting in deformation and potential failure. Torsion can lead to fatigue, reduced strength, and ultimately, structural failure in circular shafts.

| 2. How can the torsional strength of a circular shaft be calculated? |  |

Ans. The torsional strength of a circular shaft can be calculated using the formula T = (π/16) × τ_max × d^3, where T represents the torsional strength, τ_max is the maximum shear stress, and d is the diameter of the shaft. This formula assumes that the shaft is solid and made of a homogeneous material.

| 3. What are some factors that influence the torsional strength of circular shafts? |  |

Ans. Several factors influence the torsional strength of circular shafts, including the material properties (such as yield strength and modulus of elasticity), shaft geometry (such as diameter and length), and the applied torque or twisting moment. Additionally, the presence of keyways, notches, or holes in the shaft can significantly affect its torsional strength.

| 4. What are the consequences of exceeding the torsional strength of a circular shaft? |  |

Ans. Exceeding the torsional strength of a circular shaft can lead to various consequences. These include permanent deformation, cracking, and eventual failure of the shaft. Additionally, excessive torsional stress can cause vibrations, noise, and reduced performance of the shaft and any connected components or machinery.

| 5. Can the torsional strength of a circular shaft be improved? |  |

Ans. Yes, the torsional strength of a circular shaft can be improved by using materials with higher strength properties, increasing the diameter of the shaft, and optimizing the shaft's geometry to minimize stress concentrations. Additionally, reinforcing the shaft with additional supports or using design techniques like filleting can enhance its torsional strength.

|

Explore Courses for Mechanical Engineering exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.

Related Searches

θ = θ1 + θ2

θ = θ1 + θ2 θ1 = θ2

θ1 = θ2

τmax = 16T/πD3

τmax = 16T/πD3 (i) Principal stress

(i) Principal stress

(ii) Hollow Circulation Section

(ii) Hollow Circulation Section