Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:In a surface broaching process, a broach having 5 mm pitch and cut per teeth 0.05 mm is used for reducing the thickness by 6 mm. If the length of the workpiece is 50 mm and the cutting speed is 0.5 m/s, the time required/pass in second is

[PI 2006]

Explanation

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:In deep drawing of sheet metal, spring loaded stripper clamps the work until:

[PI 2004]

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:The function of draw bead in the deep drawing operation is to

[PI 1994]

Explanation

Draw beads decreases circumferential stress or buckling in flange.

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:In a bending operation, if the modulus of elasticity E is increased keeping all other parameters unehanged, the spring back will

[PI 1994]

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:Wall thickness of drawn cup is controlled by

[PI 1992]

Explanation

It is clearance between punch & die in subsequent reduction in single stroke.

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:A cup of 10 cm height and 5 cm diameter is to be made from a sheet metal of 2 mm thickness.The number of deductions necessary will be

[PI 1991]

Explanation

first reduction 50%

Next reduction 30%

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:In progressive die (for sheet metal), spring loaded stripper plate is used to clamp the stock until

[PI 1991]

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:Consider a linear elastic rectangular thin sheet of metal, subjected to uniform uniaxial tensile stress of 100 MPa along the length direction. Assume plane stress condition in the plane normal to the thickness. The Young’s modulus E = 200 MPa and Poisson’s ratio μ = 0.3 are given. The principal strains in the plane of the sheet are

[ME 2019,Set-2]

Explanation

Given

E = 200 MPa

σx = 100 MPa

σy = 0

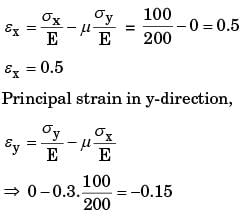

Principal strain in x-direction

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself: The value of true strain produced in compressing a cylinder to half its original length is

[ME 2016,Set-2]

Explanation

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:In the deep drawing of cups, blanks show a tendency to wrinkle up around the periphery (flange). The most likely cause and remedy of the phenomenon are, respectively.

[ME 2008]

Explanation

Due to circumferential compression buckling in circumference, by increasing blank holding force buckling decrease in lateral direction of load applied.

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:A shell of 100 mm diameter and 100 mm height with the corner radius of 0.4 mm is to be produced by cup drawing. The required blank diameter is

[ME 2003]

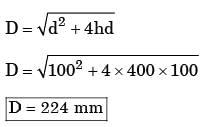

Explanation

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:Identify the stress strain in flange portion of a partially drawn cylindrical cup when deep drawing without a blank holder

[ME 1999]

Explanation

Tensile in Radial direction & compressive in circumferential direction.

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:In deep drawing of sheets, the values of limiting drawing ratio depends on

[ME 1994]

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:Wrinkling is a common defect found is

[ME 1991]

Explanation

Deep drawn components having defects of wrinkles due to less blank holding force.

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:Circular blanks of 10 mm diameter are punched from an aluminum sheet of 2 mm thickness.The shear strength of aluminum is 80 MPa.The minimum punching force required in kN is

[PI 2013]

Explanation

Punching force = πDtτ

= π × 10 × 2 × 80

= 5.023 KN

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:A disc of 200 mm diameter is blanked from a strip of an aluminum alloy of thickness 3.2 mm.The material shear strength to fracture is 150 MPa.The blanking force (in kN) is

[PI 2009]

Explanation

Banking force = πDtτ

= π × 200 × 3.2 × 150 = 301.59 KN

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:A blank of 50 mm diameter is to be sheared from a sheet of 2.5 mm thickness. The required radial clearance between the die and the punch is 6% of sheet thickness. The punch and die diameter (mm) for this blanking operation respectively are

[PI 2008]

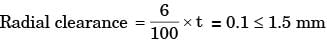

Explanation

Total clearance = 2 × 0.15 = 0.3

Die Dia will be exact = 50 mm

Clearance will be provided on punch

= 50–0.30 = 49.70 mm

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:Circular blanks of 35 mm dia are punched from a steel sheet of 2 mm thickness. If the clearance per side between the punch and die is to be kept as 40 microns. The sizes of punch and die should respectively be

[PI 2007]

Explanation

Dia of Die = 35 mm

Dia of Punch = 35 – 2 × 0.04 = 34.92mm

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself: It is required to punch a hole of diameter 10 mm on a sheet of thickness 3 mm. The shear strength of the work material is 420 MPa.The required punch force is

[PI 2006]

Explanation

Punching force = πDtτ

= π × 10 × 3 × 420 = 39.58 kN

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:It is require to punch a hole of diameter 10 mm on a sheet of thickness 3 mm. The shear strength of the work material is 420 MPa. The required punch force is

[PI 2006]

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:A ϕ 25 mm hole is pierced in a t = 2.5 mm thick steel sheet having shear strength τ = 350 MPa.If the diametral clearance is given by the expression c = 0.0064 √τ, the die diameter (in mm), punch diameter (in mm) and punch force in (kN) respectively are

[PI 2005]

Explanation

t = 2.5

τ = 350 MPa

dhole = 25 mm

Punch dia = 25 mm

Clearance = = 0.0064 x 2.5 x

= 0.3mm

Die Dia = Punch Dia + Clearance

= 25 + 0.3 = 25.3

Punching force = π Dt τ = π × 25 × 2.5 × 350

= 68.72 KN

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:Determine the load required to punch a 20 mm diameter hole in 2 mm thick sheet. The properties of the material of the sheet are: Tensile strength – 580 MPa

Yield strength in tension – 410

MPa Shear strength – 350 MPa

Yield strength in shear – 250 MPa

The load in kN is

[PI 2004]

Explanation

Punching force = πDtτ

= π × 20 × 2 × 350 = 43.98 KN

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:A hole of 40 mm diameter is pierced in a steel sheet of 4 mm thickness without shear on the tool. Shear strength of steel is 400 N/mm2 and penetration is 25%. What is the expected percentage load reduction if a shear of 1 mm is provided on the punch?

[PI 2004]

Explanation

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

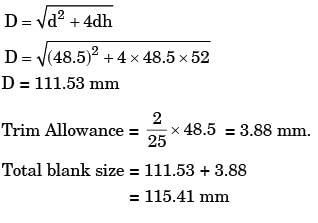

Try yourself:A cylindrical cup of 48.5 mm diameter and 52 mm height has a corner radius of 1.5 mm.Cold rolled steel sheet of thickness 1.5 mm is used to produce the cup. Assume trim allowance as 2 mm per 25 mm of cup diameter.What is the blank size in mm?

[PI 2004]

Explanation

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:Consider the following statements related piercing and blanking

1. Shear on the punch reduces the maximum cutting force

2. Shear increases the capacity of the press needed

3. Shear increases the life of the punch

4. Total energy needed to make the cut remains unaltered due to provision of shear.

Which of the above statements are correct?

[PI 2003]

Explanation

Over all Energy requirement Unaltered & Maximum Force decreased.

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:A hydraulic press is used to produce circular blanks of 10 mm diameter from a sheet of 2 mm thickness. If the shear strength of the sheet material is 400 N/mm2, the force required for producing a circular blank is

[PI 2003]

Explanation

Punching force = πDtτ

= π × 2 × 10 × 400 = 25.13 KN

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:Which one is not a method of reducing cutting forces to prevent the overloading of press?

[PI 2003]

Explanation

Shear decrease the maximum force but Energy Requirement remains the same.

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

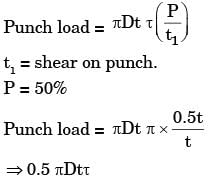

Try yourself:For 50% penetration of work material, a punch with single shear equal to thickness will

[PI 2001]

Explanation

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:In blanking operation, the best way to improve the smoothness and secureness of the edges is to

[PI 1994]

Question for GATE Past Year Questions: Sheet Metal Operations

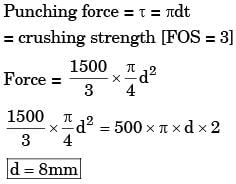

Try yourself:Calculate the smallest punch diameter that can be designed for piercing sheet metal strip with the following data. Crushing strength of the punch material is 1500 MPa. Thickness of the sheet is 2 mm, factor of safety is 3, shear strength of the sheet material 500 MPa is

[PI 1990]

Explanation

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:Internal gears are manufactured by

[ME 2014,Set-2]

Question for GATE Past Year Questions: Sheet Metal Operations

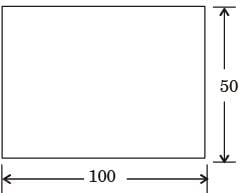

Try yourself:A rectangular hole of size 100 mm × 50 mm is to be made on a 5 mm thick sheet of steel having ultimate tensile strength and shear strength of 500 MPa and 300 MPa, respectively. The hole is made by punching process. Neglecting the effect of clearance, the punching force (in kN) is

[ME 2014,Set-2]

Explanation

Perimeter = (50 + 100) × 2 = 300

Thickness = 5

so shown Area = 300 × 5 = 1500 mm2.

Punching force = τ ×As.

= 300 × 1500 = 450 KN

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:Calculate the punch size in mm, for a circular blanking operation for which details are given below.

Size of the blank - 25 mm

Thickness of the sheet - 2 mm

Radial clearance between punch and die 0.06 mm Die allowance 0.05 mm

[ME 2012]

Explanation

Diameter of punch

= Diameter of Blank – 2 x radial clearance - die allowance

= 25 - 2 x 0.06 - 0.05 = 24.83 mm

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:The shear strength of a sheet metal is 300 MPa.The blanking force required to produce a blank of 100 mm diameter from a 1.5 mm thick sheet is close to

[ME 2011]

Explanation

Blanking force = τ x As

= 300 x πdt

= 300 x π x 100 x 1.5

= 141 kN

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:10 mm diameter holes are to be punched in a steel sheet of 3 mm thickness. Shear strength of the material is 400 N/mm2 and penetration is 40%. Shear provided on the punch is 2 mm.The blanking force during the operation will be

[ME 2004]

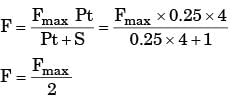

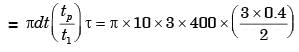

Explanation

Given, Shear strength,

τ = 400 N/mm2, Sheet thickness,

t = 3 mm

Diameter of hole,

d = 10 mm,

Shear on punch,

t1 = 2 mm

Penetration of punch on fraction,

2p = 0.4

Blanking force when shear is applied on the punch

= 22.61 kN

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

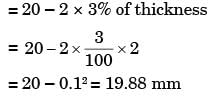

Try yourself:A metal disc of 20 mm diameter is to be punched from a sheet of 2 mm thickness. The punch and the dia clearance is 3%. The required punch diameter is

[ME 2003]

Explanation

Punch diameter

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:In blanking operation the clearance is provided on

[ME 2002]

Explanation

Blanking operation cleanness is provided on.

Punch Die will be exact.

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:The cutting force in punching and blanking operations mainly depends on

[ME 2001]

Explanation

Cutting force = t × A

t = Shear strength

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

Try yourself:A 50 mm diameter disc is to be punched out from a carbon steel sheet 1.0 mm thick. The diameter of the die should be (Take clearance as 3% of sheet thickness) _______.

[ME 1996]

Explanation

Clearness should be given on punch in Blanking operation. Die should be exact.

Report a problem

Question for GATE Past Year Questions: Sheet Metal Operations

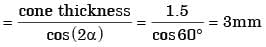

Try yourself:The thickness of the blank needed to produce, by power spinning a missile cone of thickness 1.5 mm and half cone angle 30°

[ME 1992]

Explanation

Thickness of blank

Report a problem