Q1: In an arc welding process, the vol tage and current are 30 V and 200A, respectively. The crosssectional area of the joint is 20mm2 and the welding speed is 5 mm/s. The heat required to melt the material is 20 J/s. The percentage of heat lost to the surrounding during the welding process is _______ (rounded off to 2 decimal places). (2024)

(a) 55.25

(b) 12.45

(c) 36.25

(d) 66.6

Ans: (d)

Sol:

Heat required to melt=20 J/sec= heat rate Heat required for melting

Q2: The most suitable electrode material used for joining low alloy steels using Gas Metal Arc Welding (GMAW) process is (2024)

(a) copper

(b) cadmium

(c) low alloy steel

(d) tungsten

Ans: (b)

Sol:

For general-purpose welding of low alloy steels electrode (e.g. E7018) issued for welding of low alloy steel through GMAW.

Electrode with specific alloy compositions are selected to match base metal's composition in order to achieved desired mechanical properties in the weld.

Q3: Two surfaces P and Q are to be joined together. In which of the given joining operation(s), there is no melting of the two surfaces P and Q for creating the joint? (2023)

(a) Arc welding

(b) Brazing

(c) Adhesive bonding

(d) Spot welding

Ans: (b,c)

Sol:

Soldering is define as a metal joining process wherein coalescence is produced by heating the surface to be joint to a suitable temperature and melting the filler metal which is a fusible alloy called solder (melting point usually less than 4270C). Principle underlying soldering is that when the surface to be jointed are cleaned off well from oxides they can be joined together using molten solder that may adhere easily with the workpiece. Brazing is also one of the type of welding process which is used for joining the two similar or dissimilar metal piece together by heating the surface and by using a non-ferrous filler metal having its melting point above 4270C) but below the melting point of metal to be brazed. The molten filler metal is distributed between the joint surface by the capillary action which on cooling results in a sound joint.

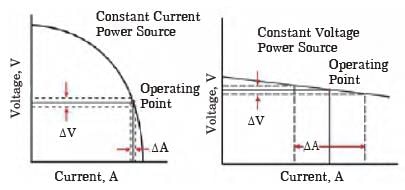

Q4: In a direct current arc welding process, the power source has an open circuit voltage of 100 V and short circuit current of 1000 A. Assume a linear relationship between voltage and current. The arc voltage (𝑉) varies with the arc length (𝑙) as(V)=10+5𝑙 where V is in volts and 𝑙 is in mm. The maximum available arc power during the process is _________ kVA (in integer). (2022Set2)

(a) 80

(b) 120

(c)180

(c) 25

Ans: (d)

Sol:

Given, OCV = 100 V and SCC = 1000 A

For stable arc

Hence, for Maximum arc power, arc length is 8 mm

Maximum Arc Power

Q5:An assignment problem is solved to minimize the total processing time of four jobs (1, 2, 3 and 4) on four different machines such that each job is processed exactly by one machine and each machine processes exactly one job. The minimum total processing time is found to be 500 minutes. Due to a change in design, the processing time of Job 4 o n each machine has increased by 20 minutes. The revised minimum total processing time will be _____________ minutes (in integer). (2022 Set1)

(a)500

(b) 460

(c) 320

(d) 520

Ans:(d)

Sol:

Minimum total processing time = 500 min

If the processing time of job 4 each machine is increased by 20 minutes then the revised minimum total processing time will be 520 minutes

Proof: Assume the following data

The assignments are

Minimum total processing time = 80+160+80+180 = 500 mins

If Job '4' times are increased by 20 mins then

The assignments are

Minimum total processing time = 80+160+80+200 = 520 mins

Q6: Two mild steel plates of similar thickness, in buttjoint configuration, are welded by gas tungsten arc welding process using the following welding parameters. (2022 Set1)

filler wire of the same mild steel material having 3 mm diameter is used in this welding process. The filler wire feed rate is selected such that the final weld bead is composed of 60% volume of filler and 40% volume of plate material. The heat required to melt the mild steel material is 10J/mm3 .The heat transfer factor is 0.7 and melting factor is 0.6. The feed rate of the filler wire is __________ mm/s (round off to one decimal place).

(a) 18.25

(b) 32.12

(c) 10.69

(d) 8.45

Ans :(c)

Sol:

Welding current = 150A

Welding voltage = 20V

Hence we can write

It means total 126 mm3 /s metal need to be deposited in the gap between Work Piece

It is given in the question that 60% of the total volume is to be filled by electrode.

Q7: A spot welding operation performed on two pieces of steel yielded a nugget with a diameter of 5 mm and a thickness of 1 mm. The welding time was 0.1 s. The melting energy for the steel is 20J/mm3 .Assuming the heat conversion efficiency as 10%, the power required for performing the spot welding operation is _________kW (round off to two decimal places). (2021 Set2)

(a) 30.5

(b)39.25

(c) 45.75

(d) 55.75

Ans:(b)

Sol:

Heat transfer efficiency =10%

Energy required to melt = 20J/mm3

Diameter of nugget =5mm

Thickness=1

Time =0.1 second

Q8: The resistance spot welding of two 1.55 mm thick metal sheets is performed using welding current of 10000 A for 0.25 s. The contact resistance at the interface of the metal sheets is 0.0001 Ω. The volume of weld nugget formed after welding is 70mm3 . Considering the heat required to melt unit volume of metal is 12 J/ mm3, the thermal efficiency of the welding process is ______% (round off to one decimal place). (2021 Set1)

(a) 33.6

(b) 14.2

(c) 36.2

(d) 48.6

Ans: (a)

Sol:

Melting efficiency = Thermal efficiency

Q9: Two plates, each of 6 mm thickness, are to be butt-welded. Consider the following processes and select the correct sequence in increasing order of size of the heat affected zone (2020 Set2)

(a) 1-4-2-3

(b) 3-4-2-1

(c) 4-3-2-1

(d) 3-2-4-1

Ans:(d)

Sol:

Processes with low rate of heat input (slow heating) tend to produce high total heat constant within the metal, slow cooling rates, and large heat-affected zones. high heat input process, have low total heats, fast cooling rates and small heat affected zones

Q10: A gas tungsten arc welding operation is performed using a current of 250A and an arc voltage of 20V at a welding speed of 5mm/s. Assuming that the arc efficiency is 70%, the net heat input per unit length of the weld will be ______kJ/mm(round off to one decimal place). (2019Set 2)

(a) 0.2

(b) 0.5

(c) 0.9

(d) 0.7

Ans: (d)

Sol:

Question for GATE Past Year Questions: Joining Processes

Try yourself:A 900 mm long steel plate is welded by manual metal arc welding process using welding current of 150 A, arc voltage of 20 V and welding speed of 300 mm/min. If the process efficiency of is 0.8 and surface resistance is 36 micro-ohm, the heat input in J/mm

[PI 2003]

Explanation

Heat Input to weld

= 480 J/mm.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:In resistance welding, heat is generated due to the resistance between

[PI 2003]

Explanation

Because of Air Resistance is very high.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:The type of weld represented by the shaded region in the figure is

[ME 2018,Set-1]

Explanation

Report a problem

Question for GATE Past Year Questions: Joining Processes

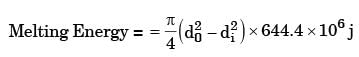

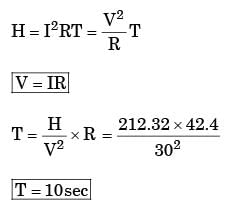

Try yourself:Two pipes of inner diameter 100 mm and outer diameter 110 mm each are joined by flash butt welding using 30 V power supply. At the interface, 1 mm of material melts from each pipe which has a resistance of 42.4 ohms. If the unit melt energy is 64.4 MJ/m3, then time required for welding (in s) is

[ME 2010]

Explanation

Energy Required for melting/volume

E= 64.4 MJ/m3

V= 30 volts

R = 42.4 Ω

di = 100 mm

do = 110 mm

= 212.32 Joules

Report a problem

Question for GATE Past Year Questions: Joining Processes

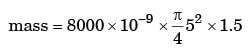

Try yourself:Spot welding of two 1 mm thick sheets of steel (density = 8000 kg/m3) is carried out successfully by passing a certain amount of current for 0.1 second through the electrodes. The resultant weld nugget formed is 5 mm in diameter and 1.5 mm thick. If the latent heat of fusion of steel is 1400 kJ/kg and the effective resistance in the welding operation is 200 μ-ohms, the current passing through the electrodes is approximately

[ME 2005]

Explanation

ρ = 8000 kJ/m3

t = 0.1 sec dn = 5 mm

hn = 1.5 mm

LH = 1400 kJ/kg R = 200 µ Ω

I = ?

= 2.356 × 10–4kg.

Heat = 1400 × 8000 × 2.356 × 10–4

= 329.8 Joules

Heat = I2 × 200 × 10–6 × 0.1

I = 4060 Amp.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:The strength of a brazed joint

[ME 2005]

Explanation

Strength increases up to some certain gap and beyond this strength decreases.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:Resistance spot welding is performed on two plates of 1.5 mm thickness with 6 mm diameter electrode, using 15000 A current for a time duration of 0.25 sec. Assuming the interface resistance to be 0.0001 ohms. The heat generated to form the weld is

[ME 2001]

Explanation

t = 1.5mm, d = 6mm,I = 15000A, t = 0.25 sec

R = 0.000 1 Ω

H = I2 Rt

= 15000 × 0.0001 × 0.25 = 5625 W-sec

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:For resistance spot welding of 1.5 mm thick steel sheets, the current required is of the order

[ME 1991]

Explanation

Air Resistance = 3300 ohm

Current required = 3300 × (– 1.5 + 1.5)

Current required = 9900 Amperes

= 10000 Amperes

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:Which of the following welding process results in the smallest heat affected zone?

[PI 2011]

Explanation

Laser beam welding will have smallest HAZ due to the fact that laser beam is very fine in nature.

Report a problem

Question for GATE Past Year Questions: Joining Processes

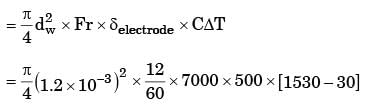

Try yourself:During a steady gas metal arc welding with direct current electrode positive polarity, the welding current, voltage and weld speed are 150 A, 30 V and 6 m/min respectively. A metallic wire electrode of diameter 1.2 mm is being fed at a constant rate of 12 m/min. The density, specific heat and melting temp of the wire electrode are 7000 kg/m3, 500 J/kg and 1530°C respectively.

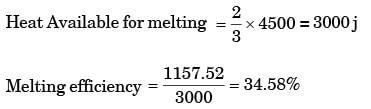

Assume the ambient temp to be 30°C and neglect the latent heat of melting. Further consider that 2/3rd of the total electrical power is available for melting of the wire electrode. The melting efficiency (in percentage) of the wire electrode is

[PI 2010]

Explanation

I = 150 A, V = 30 V

Speed V = 6m/min.

dw = 1.2 mm Fr = 12 m/min

ρelectrode = 7000 kg/m3

C = 500 kJ/kg

Tm = 1530°C TA = 30°C

Heat Required for welding

= 1187.52 Joules

Power developed = P = VI = 30 × 150 = 4500 J

Report a problem

Question for GATE Past Year Questions: Joining Processes

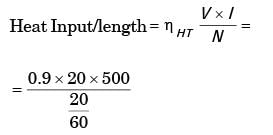

Try yourself:Autogeneous gas tungsten arc welding of a steel plate is carried out with welding current of 500 A. Voltage of 20 V and weld speed of 20 mm/ min. Consider the heat transfer efficiency from the arc to the weld pool as 90%. The heat input per unit length (in kJ/mm) is

[PI 2009]

Explanation

Current = 500 A

Voltage = 20 V

V = 20 mm/min

ηHT= 0.9

= 27 kJ/mm

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:The DC power source for arc welding has the characteristic 3V + I = 240, where V = Voltage and I = Current in amp. For maximum are power at the electrode, voltage should be set at

[PI 2007]

Explanation

Constant current characteristics:

3 V + I = 240

I = 240 – 3 V

Drooping characteristics:

P = V I = V × (240 - 3 V)

dP/dV = 0

V = 40 V

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:The current in Amperes used in resistance spot welding of plain carbon steel sheets (1 to 3 mm thick) lies within the range

[PI 2004]

Explanation

Very high current is used in air gap.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:Which of the following process can be used for welding of Aluminum alloys?

P. Submerged arc welding

Q. Gas metal arc welding

R. Electroslag welding

S. Gas tungsten arc welding

[PI 2003]

Explanation

To remove the ceramic layer of aluminium oxide, TIG is used.

Report a problem

Question for GATE Past Year Questions: Joining Processes

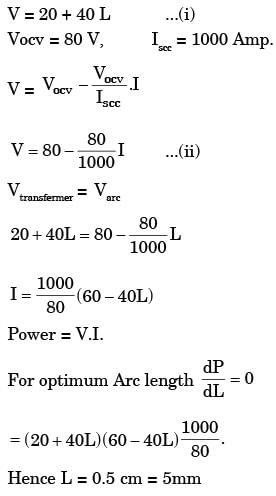

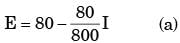

Try yourself:The voltage arc length characteristics of a DC arc is given by V = 20 + 40L, where L = arc length in cm. The power source characteristics can be approximated by a straight line. Open circuit is 80 V and short circuit current 1000 Amps. The optimum arc length in mm

[PI 1991]

Explanation

Constant voltage Characteristics

V = 20 + 40 L ...(i)

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:High alloy steel components are preheated before welding for reducing

[PI 1991]

Explanation

Due to preheating, thermal conductivity will decrease so less thermal stressese and hence less distortion will take place.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:The mode of metal transfer in CO2-MIG welding at low temperature is

[PI 1990]

Explanation

Droplet transfer because of higher surface tension force.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:In an arc welding process, welding speed is doubled. Assuming all other process parameters to be constant, the cross sectional area of the weld bead will

[ME 2017,Set-1]

Explanation

If welding speed is doubled then original cross sectional area would become half if volume remains constant. Therefore, area reduces by 50%.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:The welding process which uses a blanket of fusible granular flux is

[ME 2016,Set-2]

Explanation

In submerged arc welding, the arc is completely submerged inside the granular flux powder and thus forming as blanket.

Report a problem

Question for GATE Past Year Questions: Joining Processes

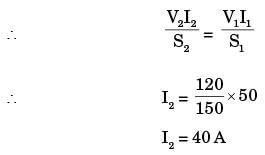

Try yourself:During a TIG welding process, the arc current and arc voltage were 50 A and 60 V, respectively, when the welding speed was 150 mm/min. In another process, the TIG welding is carried out at a welding speed of 120 mm/min at the same arc voltage and heat input to the material so that weld quality remains the same. The welding current (in A) for this process is ___________ .

[ME 2015,Set-2]

Explanation

Total heat in put = VIt

Time t is inversely proportional to weld speed (S)

Report a problem

Question for GATE Past Year Questions: Joining Processes

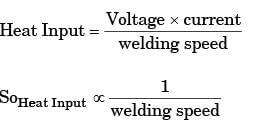

Try yourself:In a linear arc welding process, the heat input per unit length is inversely proportional to

[ME 2015,Set-1]

Explanation

Report a problem

Question for GATE Past Year Questions: Joining Processes

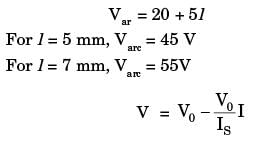

Try yourself:In a DC arc welding operation, the voltage-arc length characteristic was obtained as Varc = 20 + 5l where the arc length l was varied between 5 mm and 7 mm. Here Varc denotes the arc voltage in Volts. The arc current was varied from 400 A to 500 A. Assuming linear power source characteristic, the open circuit voltage and the short circuit current for the welding operation are

[ME 2012]

Explanation

where Vo is open circuit voltage and IS is short circuit current.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:Which one among the following welding processes uses non-consumable electrode?

[ME 2011]

Explanation

Tungsten Electrode is used to create arc only.

Reverse polarity is used to weld Aluminium metal.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:In arc welding of a butt joint, the welding speed is to be selected such that highest cooling rate is achieved. Melting efficiency and heat transfer efficiency are 0.5 and 0.7, respectively. The area of the weld cross section is 5 mm2 and the unit energy required to melt the metal is 10 J/mm3.If the welding power is 2 kW, the welding speed in mm/s is closest to

[ME 2008]

Explanation

Welding power applied = Heating power needed

⇒ P × ηm × ηH .T. = EU × (A) × f

⇒ 2 × 103 × 0.5 × 0.7 = 10 × 5 × f

⇒ f = 14 m m /sec

Report a problem

Question for GATE Past Year Questions: Joining Processes

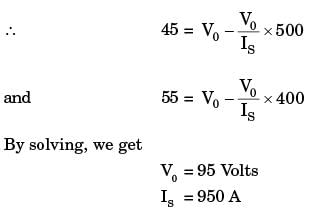

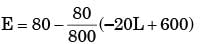

Try yourself: A direct current welding machine with a linear power source characteristic provides open circuit voltage of 80 V and short circuit current of 800 A. During welding with the machine, the measured arc current is 500 A corresponding to an arc length of 5.0 mm and the measured arc current is 460 A corresponding to an arc length of 7.0 mm.

The linear voltage (E) - arc length (L) characteristic of the welding arc can be given as (where E is in Voit and L is in mm)

[ME 2007]

Explanation

The power source characteristic can be written analytically as

The arc characteristic is given as

I = aL + b

where a and b are constant

Given,

When I = 500A

then L = 5.00 mm

∴ 500 = 5a + b ...(i)

when I = 460A

then L = 7.00 mm

∴ 460 = 7a + b ...(ii)

Solving Eqs. (i) and (ii, we get

a = –20

and b = 600

Then arc characteristic equation

I = –20L + 600

From equations (a) and (b)

= 80 – 0.1(–20L + 600)

= 80 + 2L – 60

= 20 + 2L

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:In an arc welding process, the voltage and current are 25 V and 300 A respectively. The arc heat transfer efficiency is 0.85 and welding speed is 8 mm/s. The net heat input (in J/mm) is

[ME 2006]

Explanation

V = 25 Volt, I = 300 A, η = 0.85

Weld speed = 8 mm/s.

Power Generated at arc = V.I

= 25 × 300 = 7500 J/S

Heat transferred = 0.85 × 7500

= 6375 J/S

So net Heat Input = 6375/8 = 797 J/mm.

Report a problem

Question for GATE Past Year Questions: Joining Processes

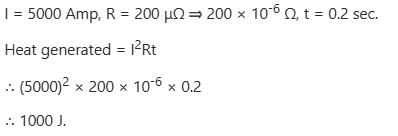

Try yourself:Two 1 mm thick steel sheets are to be spot welded at a current of 5000 A. Assuming effective resistance to be 200 micro-ohms and current flow time of 0.2 second, heat generated during the process will be

[ME 2004]

Explanation

Heat generated during the process = 12 RΔt

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:Which of the following arc welding processes does not use consumable electrode

[ME 2002]

Explanation

GTAW: Non consumable Tungsten Electrode is used & separate filler material is used.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:Two plates of the same metal having equal thickness are to be butt welded with electric arc.When the plate thickness changes, welding is achieved by

[ME 2002]

Explanation

Increasing the current setting increases the heat generation, so larger material Deposition takes place.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:Preheating before welding is done to

[ME 1996]

Explanation

Preheating is often employed when welding cast iron, high carbon steel, or alloy steel since preheating slows down the cooling rate of that area of parent metal close to the weld itself and thereby prevents the formation of martensite which accounts for hardness across the weld. The change of cracking in the heat-cooling is also minimized by preheating.

Preheating: Heating the job before welding operation is known as 'preheating'. The purpose of the preheating of the cast-iron job is to reduce cracking due to distortion. The rate of cooling, and gas consumption, etc. are also reduced.

Cast Iron is welded after performing preheating to a temperature of 200°C - 210°C. On completion of the first layer of welding, the same preheating is repeated to maintain the reinforcement of weld. Next, the whole job is evenly heated. This is called a post-heating.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:The electrodes used in arc welding are coated.This is not expected to

[ME 1994]

Explanation

Coating is provided for first three options not for prevention from external contaminates.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:In DC welding, the straight polarity (electrode negative) results in

[ME 1993]

Explanation

Lower penetration because of 2/3rd heat is generated at work piece so lower deposition rate of consumable electrode or filter material can be observed.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:At small variations of arc length at operating conditions, the manual metal arc welding transformer provides nearly

[ME 1990]

Explanation

Constant current type of transformer is used in Manual Arc welding otherwise weld bead of irregular shape and penetration

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:Penetration is increased by

[ME 1990]

Explanation

By increasing the current, large heat is generated and due to lesser speed heat is generated at particular area so that larger penetration can be carried out.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:Which of the following powders should be fed for effective oxy-fuel cutting of stainless steel.

[PI 2001]

Explanation

Powder of steel is used with oxygen such a flame.

This powder burns producing large amount of heat facilitating cutting.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:During gas welding of copper sheets a neutral flame was used consuming 8 litres of acetylene.But the weld was found to be defective. So it was rewelded using an oxidizing flame. The likely consumption of oxygen in litres will be

[PI 1993]

Question for GATE Past Year Questions: Joining Processes

Try yourself:In welding a mild steel sheet using an oxyacetylene flame, the total amount of acetylene consumed was 8.0 litres, the oxygen consumption from the cylinder is

[PI 1989]

Question for GATE Past Year Questions: Joining Processes

Try yourself:The temperature of a carburizing flame in gas welding that of a neutral or an oxidizing flame

[ME 2002]

Explanation

Due to insufficient acetylene, complete oxygen is not utilized that is why lower temperature than neutral or oxidising flame.

Carburising flame – 2900°C

Neutral flame – 3100°C

Oxidising flame – 3300°C

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:For butt welding 40 mm thick steel plates, when the expected quantity of such jobs is 5000 per month over a period of 10 years, choose the best suitable welding process out of the following available alternatives.

[ME 1999]

Explanation

No. of jobs is very high, therefore we need a welding process which is capable of welding in one pass. Therefore, SAW is chosen over others.

Report a problem

Question for GATE Past Year Questions: Joining Processes

Try yourself:For gas welding a particular job using a neutral oxyacetylene flame the acetylene consumption was 10 litres. The oxygen consumption from the cylinder in liters will be

[ME 1991]

Explanation

In neutral flame, volume of both oxygen and acetylene are equal.

Report a problem