Question for GATE Past Year Questions: Machining Processes

Try yourself:Grinding ratio is defined as Volume of wheel wear

Question for GATE Past Year Questions: Machining Processes

Try yourself:The binding material used in cemented carbide cutting tools is

[PI 2011]

Explanation

Cobalt used as a binding agent in cemented carbide tool. which increases the grain size transverse rapture strength increases & hot hardness decreases.

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:During turning of a low carbon steel bar with TiN coated carbide insert, one needs to improve surface finish without sacrificing material removal rate. The achieve improved surface finish one should

[PI 2010]

Explanation

By increasing nose radius, surface finish increases.

Report a problem

Question for GATE Past Year Questions: Machining Processes

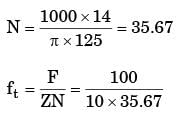

Try yourself:A side and face cutter 125 mm diameter has 10 teeth. If operates at a cutting speed of 14 m/ min with a table traverse 100 mm/min the feed per tooth of the cutter is

[PI 2002]

Explanation

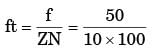

D = 125 mm Z = 10 teeth V = 14 m/min

F = 100 m/min

ft = 0.25 mm/tooth

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:A grinding wheel is said to be glazed if

[PI 1995]

Explanation

Glazing is when hard material is grounded by hard wheel.

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:If the index crank of a dividing head is turned through one complete revolution and 10 holes in a 30 hole Circle plate, the workpiece turns through (in degrees)

[PI 1992]

Explanation

By one complete revolution of indexing crank the work piece turned through = 360/40 = 9

and by 1/3 Rotation 9/3 = 9

total rotation or turn of workpiece = 9 + 3 = 12°

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:Find the speed range ratio for the drilling machine spindle if the minimum and maximum diameters of drills used are 5 mm and 25 mm respectively and if the machinability indices for the work materials are 120 (brass) and 40 (alloy steel)

[PI 1992]

Question for GATE Past Year Questions: Machining Processes

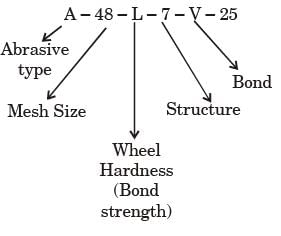

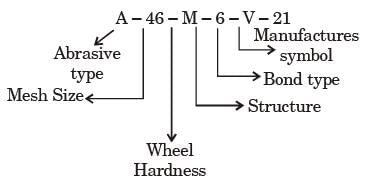

Try yourself:In a grinding wheel marked with AA-48-L-7-V25, L refers to

[PI 1992]

Explanation

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:A drilling machine has to be designed with 8 spindle speeds ranging approximately between 120 to 1200 rpm. The 5th spindle speed is

[PI 1991]

Explanation

Nmin = 120 Nmax = 1200

N = 8

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:Assertion (A): Single start threads are used for fastening purposes.

Reason (R): Single start threads are easier to produce in a lathe.

[PI 1990]

Explanation

Single start thread on be made by single point cutting tool.

Report a problem

Question for GATE Past Year Questions: Machining Processes

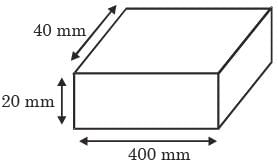

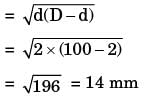

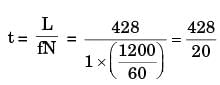

Try yourself:The length, width and thickness of a steel sample are 400 mm, 410 mm, 40 mm and 20 mm, respectively. Its thickness needs to be uniformly reduced by 2 mm in a single pass by using horizontal slab miling. The miling cutter (diameter : 100 mm, width ; 50 mm) has 20 teeth and rotates at 1200 rpm. The feed per tooth is 0.05 mm. The feed direction is along the length of the sample. If the over-travel distance is the same as the approach distance, the approach distance and time taken to complete the required machining task are :

[ME 2019,Set-1]

Explanation

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:Better surface finish is obtained with a large rake angle because

[ME 2014,Set-4]

Explanation

As rake angle increase shear plane decreases so smaller force one required so smooth machining operation

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:Cutting tool is much harder than the workpiece.Yet the tool wears out during the tool-work interaction, because

[ME 2014,Set-3]

Explanation

Metal cutting takes place in plastic deformation zone where work hardening takes place as chip get strained.

Report a problem

Question for GATE Past Year Questions: Machining Processes

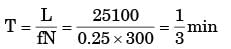

Try yourself:The time taken to drill a hole through a 25 mm thick plate with the drill rotating at 300 rpm and moving at a feed rate of 0.25 mm/rev is

[ME 2002]

Explanation

T = 20 sec

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:The hardness of a grinding wheel is determined by the

[ME 2002]

Explanation

Bond strength gives the hardness of wheel for soft material strong bond material is used for hard material soft bond material is used.

Report a problem

Question for GATE Past Year Questions: Machining Processes

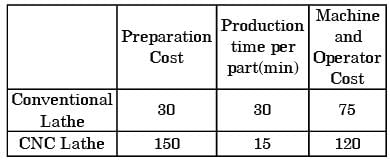

Try yourself:A conventional lathe and a CNC lathe are under consideration for machining a given part. The relevant data are shown below:

The machine preferred for producing 100 pieces is

[ME 2000]

Question for GATE Past Year Questions: Machining Processes

Try yourself:Abrasive material used in grinding wheel selected for grinding ferrous alloys is

[ME 2000]

Explanation

Less chance of wheel wear. Other wise all other to ferrous material.

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:Plain milling of mild steel plates produces

[ME 1995]

Question for GATE Past Year Questions: Machining Processes

Try yourself:Among the conventional machining processes, maximum specific energy is consumed in

[ME 1995]

Explanation

Grinding because of smaller chips, large cutting area.

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:Cutting power consumption in turning can be significantly reduced by

[ME 1995]

Explanation

By increasing the back rake angle the drag between chip & tool decreased hence cutting power consumption decreased.

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:A grinding wheel A 27 K 7 V is specified for finish grinding of a HSS cutting tool. What do you understand about the wheel from the above code.

Is this an appropriate choice?

[ME 1994]

Explanation

Grain size is given for rough cut.

27 → rough cut

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:A milling cutter having 8 teeth is rotating at 150 rpm. If the feed per tooth is 0.1 mm, the speed in mm per minute is

[ME 1993]

Explanation

F = ft ZN

= 0.1 × 8 × 150

F = 120mm/min

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:A milling cutter having 10 teeth is rotating at 100 rpm. The table feed is set at 50-mm per minute. The feed per tooth in mm is

[ME 1991]

Explanation

ft = 0.05 mm

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:For cutting double start screw threads of pitch 1.0 mm on a lathe, the thread cutting tool should have a feed rate of

[ME 1991]

Explanation

Pitch = 1mm

Start = Double Start

Feed rate = 2 × 1 = 2 mm/res.

Report a problem

Question for GATE Past Year Questions: Machining Processes

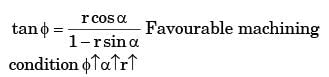

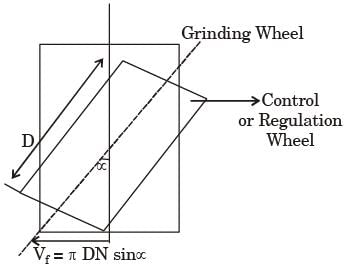

Try yourself:If the longitudinal feed in centreless grinding is expressed by Vf = πDN sinα, D stands for

[ME 1990]

Explanation

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:Pure metal pose machinability problem in turning operations. The reason is the

[ME 1988]

Explanation

Pure metals are ductile, produces long & continuous chip

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:Cutting speed in grinding is set to a high value to

[ME 1988]

Question for GATE Past Year Questions: Machining Processes

Try yourself:The ideal cutting fluid for low speed machining of metals should be one which

[ME 1988]

Explanation

Function of cutting fluid

(1) Cooling

(2) Lubrication

(3) Cleaning

(4) Save from external contamination.

Report a problem

Question for GATE Past Year Questions: Machining Processes

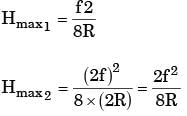

Try yourself:If in a turning operation both the feed rate and the nose radius are doubled the surface finish value will be

[ME 1987]

Explanation

High of surface roughness be doubled means surface finished hill be decreased by 50%

Report a problem

Question for GATE Past Year Questions: Machining Processes

Try yourself:The standard specification of a grinding wheel is A-46-M-6-V-21. It means a wheel of

[ME 1987]

Explanation

Report a problem