Question for GATE Past Year Questions: Bolted, Riveted & Welded Joint

Try yourself:A 60 mm long and 6 mm thick fillet weld carries a steady load of 15 kN along the weld. The shear strength of the weld material is equal to 200 MPa.

The factor of safety is

[2006]

Explanation

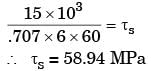

P = .707 t × Le × τS.

Given shear strength of material = 200 MPa

FOS = 200/58.94 = 3.4

Report a problem

Question for GATE Past Year Questions: Bolted, Riveted & Welded Joint

Try yourself:Weldments in fabricated steel be ams are designed for

[1987]

Question for GATE Past Year Questions: Bolted, Riveted & Welded Joint

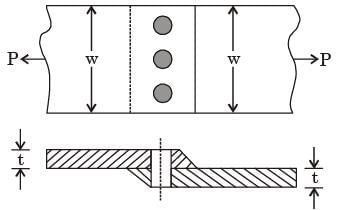

Try yourself:A single riveted lap Joint of two similar plates as shown in the figure below has the following geometrical and material details.

width of the plate ω = 200 mm, thickness of the plate t = 5 mm, number of rivets n = 3, diameter of the rivet dr = 10 mm, diameter of the rivet hole dr = 11 M mm, allowable tensile stress of the plate σp = 200 MPa, allowable shear stress of the rivet σs = 100 MPa and allowable bearing stress of the rivet σc = 150 MPa.

If the plates are to be designed to avoid tearing failure, the maximum permissible load P in kN is

[2013]

Explanation

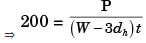

For plates, σ = P/A

P = 167kN

Report a problem

Question for GATE Past Year Questions: Bolted, Riveted & Welded Joint

Try yourself:A single riveted lap Joint of two similar plates as shown in the figure below has the following geometrical and material details.

width of the plate ω = 200 mm, thickness of the plate t = 5 mm, number of rivets n = 3, diameter of the rivet dr = 10 mm, diameter of the rivet hole dr = 11 M mm, allowable tensile stress of the plate σp = 200 MPa, allowable shear stress of the rivet σs = 100 MPa and allowable bearing stress of the rivet σc = 150 MPa.

If the rivets are to be designed to avoid crushing failure, the maximum permissible load P in kN is

[2013]

Explanation

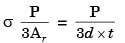

For rivet,

∴ Ps = 100 × d × t × 3 = 15 kN

and Pc = 150 × d × t × 3 = 22.5 kN

∴ p = max (15, 22.5) = 22.5 k N

Report a problem

Question for GATE Past Year Questions: Bolted, Riveted & Welded Joint

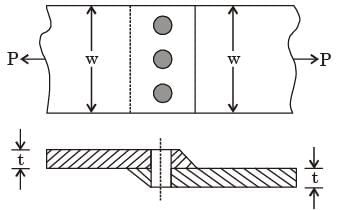

Try yourself:A bracket (shown in figure) is rigidly mounted on wall using four rivets. Each rivet is 6 mm in diameter and has an effective length of 12 mm.

Direct shear stress (in MPa) in the most heavily loaded rivet is

Explanation

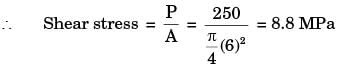

Given : Number of rivets = 4,

Diameter of each rivet , d = 6 × 10-3 m Direct load on the bracket = 1000 N since there is no eccentricity

∴ Load on each rivet = 1000/4 = 250 N

Report a problem

Question for GATE Past Year Questions: Bolted, Riveted & Welded Joint

Try yourself:If the ratio of the diameter of rivet hole to the pitch of rivets is 0.25, then the tearing efficiency of the Joint is

[1996]

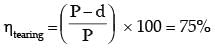

Explanation

d/P = 0.25

Report a problem

Question for GATE Past Year Questions: Bolted, Riveted & Welded Joint

Try yourself:Pre-tensioning of a bolted Joint is used to

[2018, Set-2]

Explanation

Pre-tensioning increases the stiffness of the bolt.

Report a problem

Question for GATE Past Year Questions: Bolted, Riveted & Welded Joint

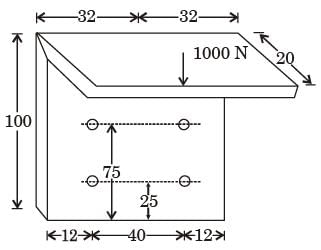

Try yourself:A steel plate, connected to a fixed Channel using three identical bolts A, B and C, carries a load of 6 kN as shown in the figure.

Considering the effect of direct load and moment, the magnitude of resultant shear force (in kN) on bolt C is

[2017, Set-2]

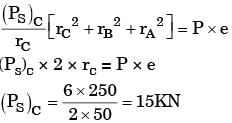

Explanation

PP = P/n = P/3 = 2kN

rA = rC = 50, (PS)A = (PS)C

rB = 0 ⇒ (PS)B = 0

QA = 180°, QC = 0°

Resultant shear force

(RC) = PP + (PS)C.

RC = 2 + 15 = 17 KN

Report a problem

Question for GATE Past Year Questions: Bolted, Riveted & Welded Joint

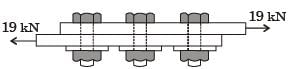

Try yourself:For the three bolt system shown in the figure, the bolt material has shear yield strength of 200 MPa. For a factor of safety of 2, the minimum metric specification required for the bolt is

[2014, Set-2]

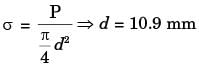

Explanation

σy = 200 MPa

P = 19 × 103 N

M10

Report a problem

Question for GATE Past Year Questions: Bolted, Riveted & Welded Joint

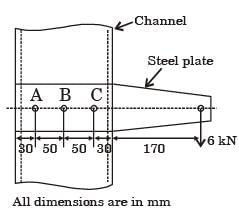

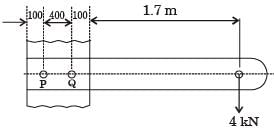

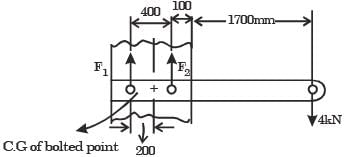

Try yourself:A steel bar of 10 × 50 mm is cantilevered with two M12 bolts (P and Q) to support a static load of 4 kN as shown in the figure.

The resultant shear stress on bolt P is closest to:

[2008]

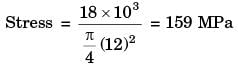

Explanation

Resultant load on P = Fsec – Fprim

= 20 – 2 = 18 kN

Report a problem

Question for GATE Past Year Questions: Bolted, Riveted & Welded Joint

Try yourself:A steel bar of 10 × 50 mm is cantilevered with two M12 bolts (P and Q) to support a static load of 4 kN as shown in the figure.

The primary and secondary shear loads on bolt P, respectively, are

Explanation

Let F1 and F2 resist the 4 kN eccentric oad. The primary shear load is due to a direct shear stress of 4kN, which is equally divided amongst the two bolts, i.e. 2 kN,

∴ Fprimary on P = 2 kN

The secondary load is to resist the moment produced by the eccentric load 4 kN about the C.

G. of the joint

Moment M = 4 k N × 2000 mm

= 8000

Nm Now this moment must be balanced by a moment produced by equal and opposite forces i.e. secondary loads on the bolts i .e. F × 400 = 800 N m

⇒ F = 20 k N

Report a problem

Question for GATE Past Year Questions: Bolted, Riveted & Welded Joint

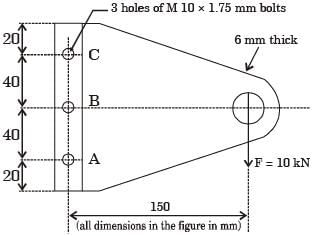

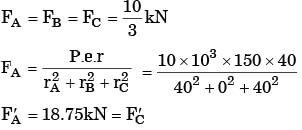

Try yourself:A bolted Joint is shown below. The maximum shear stress, in MPa, in the bolts at A and B, respectively are

[2007]

Explanation

Shear load at A and C

(τmax)A,C = 242.5MPa

(τmax)B = 42.44MPa

Report a problem

Question for GATE Past Year Questions: Bolted, Riveted & Welded Joint

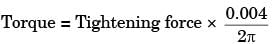

Try yourself:In a bolted Joint two smooth members are connected with an axial tightening force of 2200 N. If the bolt used has metric threads of 4 mm pitch, the torque required for achieving the tightening force is

[2004]

Explanation

Tightening force = 2200 N

Pitch = 4 mm = 0.004 m

= 1.4 N-m

Report a problem

Question for GATE Past Year Questions: Bolted, Riveted & Welded Joint

Try yourself:Bolts in the flanged end of pressure vessel are usually pre-tensioned. Indicate which of the following statements is true

[1998]

Question for GATE Past Year Questions: Bolted, Riveted & Welded Joint

Try yourself:The bolts in a rigid flanged coupling connecting two shafts transmitting power are subjected to

[1996]