Metal Forming | Manufacturing Engineering - Mechanical Engineering PDF Download

Introduction

Metal forming processes, also known as mechanical working processes, are primary shaping processes in which a mass of metal or alloy is subjected to mechanical forces. Under the action of such forces, the shape and size of metal piece undergo a change. By mechanical working processes, the given shape and size of a machine part can be achieved with great economy in material and time.

Hot and Cold Working

- Cold working may be defined as plastic deformation of metals and alloys at a temperature below the recrystallization temperature for that metal or alloy. In cold working process the strain hardening which occurs as a result of mechanical working, does not get relieved.

- Hot working may be explained as plastic deformation of metals and alloys at such a temperature above recrystallization temperature at which recovery and recrystallization take place simultaneously with the strain hardening.

Advantages & Disadvantages Cold and Hot Working Process

- As cold working is practically done at room temperature, no oxidation or tarnishing of surface takes place. No scale formation is there, hence there is no material loss where as in hot working, there is scale formation due to oxidation.

- Cold working results in better dimensional accuracy and a bright surface.

- In cold working heavy work hardening occurs which improves the strength and hardness of bars.

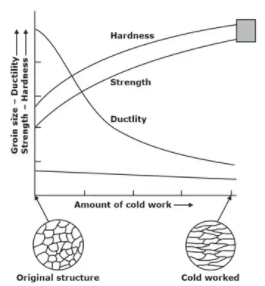

Variation of properties with cold working

Variation of properties with cold working

Due to limited ductility at room temperature, production of complex shapes is not possible by cold working processes.

Severe internal stresses are induced in the metal during cold working.

Flow Stress

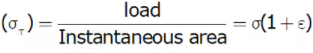

(i) True Stress

The true stress is defined as the ratio of the load to the cross-section area at any instant

where σ and ε is the engineering stress and engineering stress and engineering strain respectively.

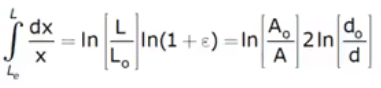

(ii) True Strain

(ετ) = Elongation/Instantaneous length =

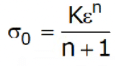

Mean Flow stress

Mean flow stress is the stress at which material begins to flow. When a material deforms plastically strain hardening occurs.

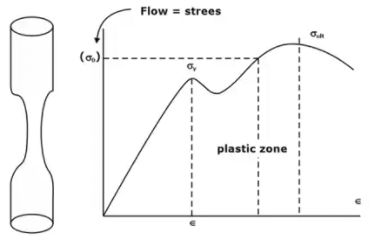

Stress-Strain curve with work hardening

Stress-Strain curve with work hardening

Here σo is flow stress.

Forging

Forging is a basic process in which the work piece is shaped by compressive forces applied through various dies and tooling.

Simple forging operations can be performed with a heavy hammer and an anvil, as has been done traditionally by blacksmiths. However, most forgings require a set of dies and such equipment as a press or a powered forging hammer.

Forging may be carried out at room temperature (cold forging) or at elevated temperatures (warm or hot forging) depending on the homologous temperature.

Cold forging requires higher forces (because of the higher strength of the work piece material, and the work piece material must possess sufficient ductility at room temperature to undergo the necessary deformation without cracking.

Based on the nature of material flow and constraint on flow by the die/punch, forging is classified as open die forging, impression die forging and flash less forging.

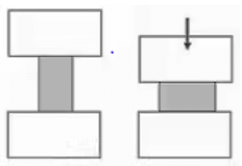

(i) Open Die Forging

In this, the work piece is compressed between two platens. There is no constraint to material flow in lateral direction.

Open-die forging

Open-die forging

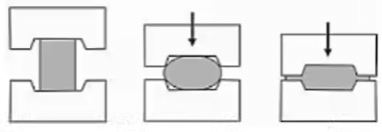

(ii) Closed Die Forging

In closed die forging a calculated amount of material is kept inside the die cavity and force is applied by the punch

Closed-die forging

Closed-die forging

(iii) Impression Die Forging

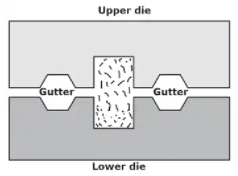

When the closed die forging is equipped with flash and gutter it is called impression die forging.

Impression die forging

Impression die forging

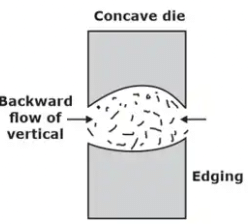

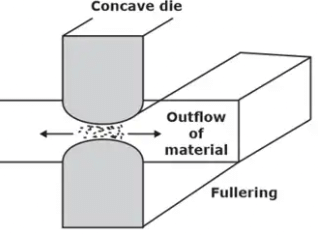

(iv) Edging and Fullering

In edging material flow towards centre of die, the objective is to reduce length. In fullering material flow away from centre of die, objective is to increase length and decrease cross sectional area.

(v) Upsetting

In many cases, only of portion of the job needs to be forged. A common example is the forging of the bolt head at one end of a rod. Such a localized forging operation is commonly known as upsetting.

(vi) Drop Forging

Drop forging utilizes a closed impression die to obtain the desired shape of the component. The shaping is done by the repeated hammering given to the material in the die cavity. The equipment used for delivering the blows are called drop hammers.

(vii) Press Forging

Press forging dies are similar to drop forging dies as also the process. In press forging the metal is shaped not by means of a series of blows as in drop forging, but by means of a single continuous squeezing action.

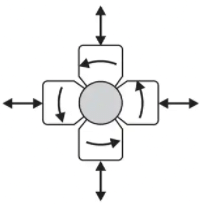

(viii) Swaging

Swaging is a special variation of impact forging where the repeated blows are obtained by a radial movement of shaped dies.

Principle of rotary Swaging

Principle of rotary Swaging

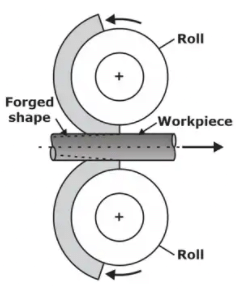

(a) Roll Forging

Roll forging is performed with two semicircular, grooved rolls held by two parallel shafts. The process is used for reducing the diameter of rods.

Principle of Roll Forging

Principle of Roll Forging

Forging Defects

Incomplete forging—either due to less material or inadequate or improper flow of material.

Mismatched forging due to improperly aligned die halves.

Scale pits—due to squeezing of scales into the metal surface during hammering action.

Internal cracks in the forging which are caused by use of heavy hammer blows and improperly heated and soaked material.

Fibre flow lines disruption due to very rapid plastic flow of metal.

When hot work comes in contact with the colder die, there will be decrease in temperature of surface coming in contact with dies and upon applying the load, since central portion has lower flow stresses it will move faster than material near the edge, this results in non cylindrical component and defect is known as Barreling defect.

Rolling

In this process, metals and alloys are plastically deformed into semi-finished or finished products by being pressed between two rolls which are rotating.

The material is subjected to high compressive force as it is squeezed (and pulled along) by the rolls. This is a process to deal with material in bulk in which the cross-section of material is reduced and its length increased.

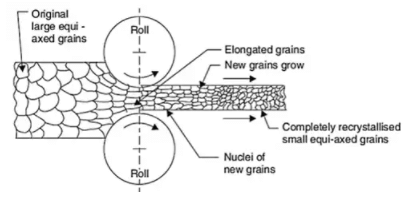

Grain refinement by rolling

Grain refinement by rolling

Different types of rolling mills are described below in brief:

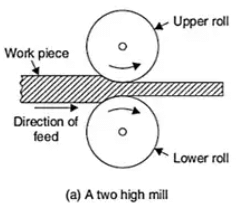

(i) Two High Mills

It comprises of two heavy rolls placed one over the other. The rolls rotate in opposite directions and are driven by powerful electrical motors. Usually the direction of rotation of rolls cannot be altered, thus the work has to be fed into rolls from one direction only.

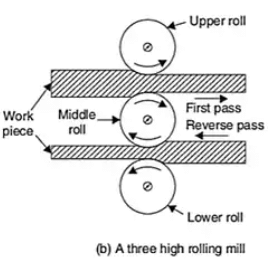

(ii) Three High Mills

(ii) Three High Mills

It consists of three rolls positioned directly over one another as shown below. The direction of rotation of the first and second rolls are opposite as in the case of two high mill. The direction of rotation of second and third rolls is again opposite to each other. All three rolls always rotate in their bearings in the same direction. The advantage of this mill is that the work material can be fed in one direction between the first and second roll and the return pass can be provided in between the second and third rolls.

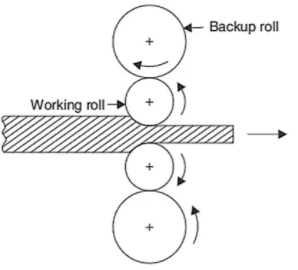

(iii) Four High Mills

(iii) Four High Mills

This mill consists of four horizontal rolls, two of smaller diameter and two much larger ones. The larger rolls are called backup rolls. The smaller rolls are the working rolls, but if the backup rolls were not there, due to deflection of rolls between stands, the rolled material would be thicker in the centre and thinner at either end.

Four-high mill

Four-high mill

Defects in Rolling

- Several surface defects (such as scale, rust, scratches, gouges, pits, and cracks) have been identified in sheet metals. These defects may be caused by inclusions and impurities in the original cast material.

- Wavy edges on sheets are the result of roll bending. The strip is thinner along its edges than at its centre).; thus, the edges elongate more than the centre.

- The cracks are usually the result of poor material ductility at the rolling temperature.

- If any impurity is present over the surface of workpiece, after forming it gets collected at the centre. When these impurity increases beyond a certain value it weakens the centre and sheet can be bifurcated into two parts. This defect is called crocodile crack or alligator defect.

- In uncambered rolls, the thickness of the rolled strip is more at centre.

Extrusion

Extrusion is a process in which the metal is subjected to plastic flow by enclosing the metal in a closed chamber in which the only opening provided is through a die. The material is usually treated so that it can undergo plastic deformation at a sufficiently rapid rate and may be squeezed out of the hole in the die.

Types of Extrusion Processes

Extrusion processes can be classified as followed:

(i) Hot Extrusion

(a) Forward or Direct extrusion.

(b) Backward or Indirect extrusion.

(ii) Cold Extrusion

(a) Hydrostatic extrusion.

(b) Impact extrusion.

Hot Extrusion Process

In this process, the material to be extruded is in the form of a block. In the front portion of the chamber, a die with an opening in the shape of the cross-section of the extruded product, is fitted. the heated material is forced to squeeze through the die-opening in the form of a long strip of the required cross-section.

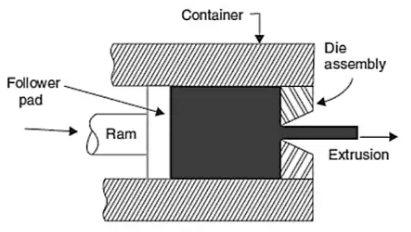

Forward or Direct Extrusion

Forward or Direct Extrusion

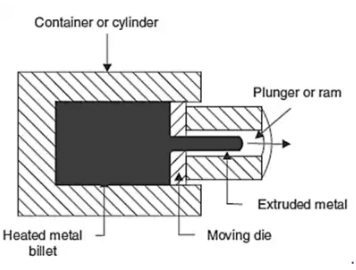

(ii) Backward or Indirect Extrusion

This process is called backward extrusion process as the flow of material is in a direction Opposite to the movement of the ram. In the forward extrusion process the flow of material and ram movement were both in the same direction.

Backward Extrusion

Backward Extrusion

Cold Extrusion Process

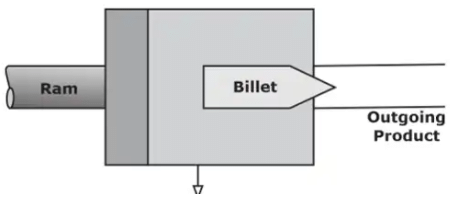

(i) Hydrostatic Extrusion

This is a direct extrusion process, but the pressure is applied to the metal blank on all sides through a fluid medium. Relatively brittle materials can also be successfully extruded by this method.

Hydrostatic Extrusion

Hydrostatic Extrusion

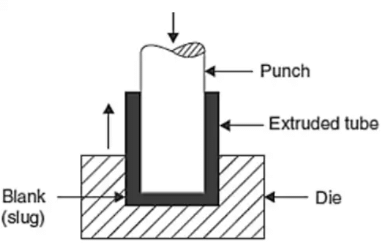

(ii) Impact Extrusion

In this process, the punch descends with high velocity and strikes in the centre of the blank which is placed in a die. The material deforms and fills up the annular space between the die and the punch flowing upwards.

Extrusion Defects

(i) Surface Cracking

Sometimes the surface of extruded metal/products develops surface cracks. If extrusion temperature, friction, or speed is too high, surface temperatures can rise significantly, which may cause surface cracking and tearing. These cracks are intergranular (i.e., along the grain boundaries. and usually are caused by hot shortness. Because of the similarity in appearance to the surface of a bamboo stem, it is known as a bamboo defect.

(ii) Piping

The type of metal-flow pattern in extrusion tends to draw surface oxides and impurities toward the centre of the billet-much like a funnel. This defect is known as pipe defect.

(iii) Internal Cracking

The centre of the extruded product can develop cracks, called center cracking, center-burst, arrowhead fracture.

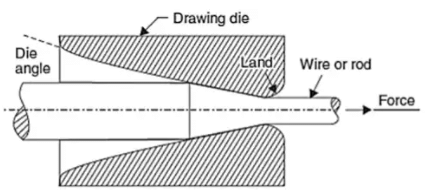

Wire Drawing

Wire drawing process is a cold working process used to produce wires from solid rods by pulling through a stationary die. In this process, rods made of steel or nonferrous metals and alloys are pulled through conical dies having a hole in the centre. As the material is pulled through the cone, it undergoes plastic deformation and it gradually undergoes a reduction in its diameter.

Wire Drawing Process

Wire Drawing Process

|

53 videos|53 docs|29 tests

|

FAQs on Metal Forming - Manufacturing Engineering - Mechanical Engineering

| 1. What is metal forming in mechanical engineering? |  |

| 2. What are the advantages of metal forming? |  |

| 3. What are the different types of metal forming processes? |  |

| 4. What factors should be considered in metal forming design? |  |

| 5. What are the limitations of metal forming processes? |  |

|

Explore Courses for Mechanical Engineering exam

|

|