Highway Materials | Transportation Engineering - Civil Engineering (CE) PDF Download

Group Index of Soils (G.I)

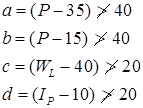

In order to classify the fine-grained soils within one group and for judging their suitability as subgrade material, an indexing system has been introduced in HRB classification which is termed as group index. Soils are thus assigned arbitrary numerical numbers known as group index (GI). Group index is function of percentage and is given by the equation G.I = 0.2a + 0.005ac + 0.01bd

Where,

Where, WL = Liquid limit, IP = Plasticity Index.

P = Percentage fines passing from 0.074 mm sieve.

0 ≤ G . I ≤ 20 Lower the group → best quality.

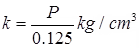

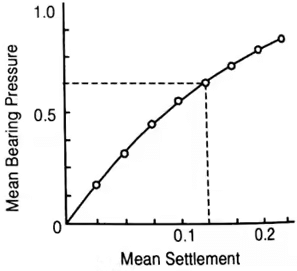

Plate Bearing Test

(i)

Here,

k = Modulus of subgrade reaction

P = Pressure Corresponding to settlement of 0.125 cm. (ii)

(ii)

Where,

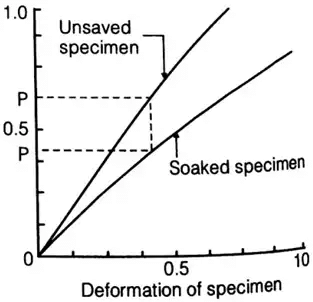

ks = Modulus of subgrade reaction for soaked condition.

Ps = Pressure required in the soaked condition to produce same deformation as deformation Produce by pressure ‘P’ in consolidated condition.

k = Modulus of subgrade reaction for the consolidated stage. Δ = Deformation in ‘cm’.

Δ = Deformation in ‘cm’.

a = Radius of rigid plate in ‘cm’.

k = P / Δ = E / 1.18a

E = Modulus of elasticity of soil subgrade in kg/cm2.

k.a = constant

a1 = Radius of smaller plate (other plate)

k1 = Modulus of subgrade reaction of other plate of radius ‘a1’ cm.

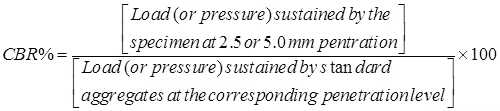

California Bearing Ratio (CBR) Test

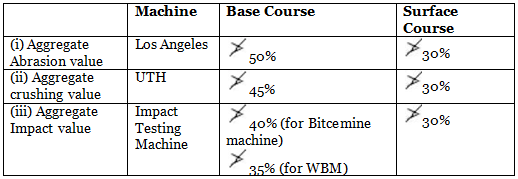

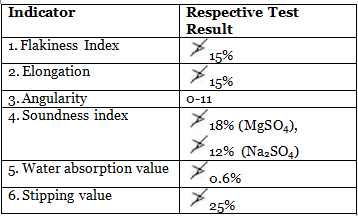

Test for Road Aggregate

(i) Aggregate crushing test

Aggregate crushing value

Where, w1 = Weight of the test sample in ‘gm’

w2 = weight of the crushed material in ‘gm’ passed through 2.36 mm sieve.

(ii) Shape Tests

Where, Ga = specific gravity of aggregate

W = mass of mould containing aggregate

C = mass of mould containing water

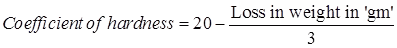

(iii) Abrasion Test

(a) Los Angeles Abrasion Test

Bituminous Material

- Product of fractional distillation of Petroleum: Gasoline, Naptha, Kerosene, Lubricating oil and Residue – Petroleum Bitumen.

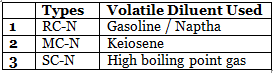

- Cutback Bitumen: Reduced Viscosity Bitumen

N – Numeral [0, 1, 2, 3, 4, 5]

Show progressive thickening from 0 to 5 - Specific Gravity:

Bituminous → 0.97 – 1.02

Tar → 1.1 – 1.5

- Bituminous Mixes

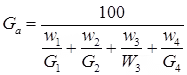

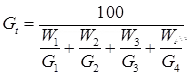

(i) Determination of Specific Gravity

Where, Ga = Average specific gravity of blended aggregate mix.

w1, w2, w3, w4 are % by weight of aggregate 1, 2, 3 & 4 respectively. G1, G2, G3 & G4 are specific gravities of the aggregate 1, 2, 3 & 4 respectively.

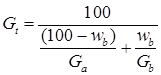

(ii) Specific Gravity of Compacted Specimen

(a)

Where, Gt = Theoretical maximum specific gravity of the mix.

Wb = % by weight of bitumen.

Gb = Specific gravity of bitumen.

Ga = Average specific gravity of aggregates.

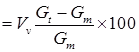

(b) Theoretical density γt, per-cent solids by volume

Where, G = Actual specific gravity of test specimen

Gt = Theoretical maximum specific gravity.

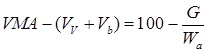

(c) Voids in the Mineral Aggregate (VMA)

Where, Vb = % of bitumen

Wa = Aggregate content percent by weight

Vv = % air voids in the specimen.

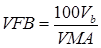

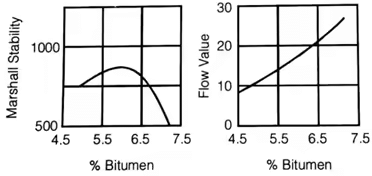

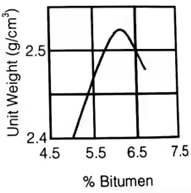

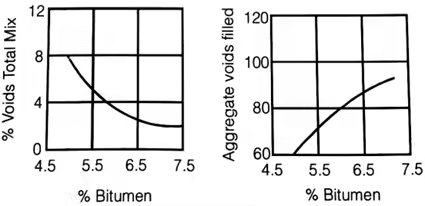

(d) % Voids Filled with Bitumen (VFB) - Marshall Method Bituminous Mix Design

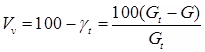

Percentage Air Voids

Where, Gm = Bulk density or mass density of the specimen

Gt = Theoretical specific gravity of mixture

Where,

W1 = Percent by weight of coarse aggregate in total mix

W2 = Percent by weight of fine aggregate in total mix

W3 = Percent by weight of filler in total mix

W4 = Percent by weight of bitumen in total mix

G1 = Apparent specific gravity of coarse aggregate

G2 = Apparent specific gravity of fine aggregate

G3 = Apparent specific gravity of filter

G4 = Specific gravity of bitumen

Percent Voids in Mineral Aggregate (VMA)

VMA = Vv + Vb

Here, Vv = Volume of air voids, %

Vb = Volume of bitumen,

Per-cent Voids Filled with Bitumen (VFB)

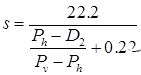

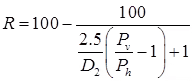

HveeM Method of Bituminous mix Design Stabilimeter Value, (s)

Where, Pv = Vertical pressure at 28 kg/cm2 or at a total load of 2268 kg.

Ph = Horizontal pressure corresponding to Pv = 28 kg/cm2.

D2 = Displacement on specimen represented as number of turns of pump handle to raise Ph from 0.35 to 7 kg/cm2.

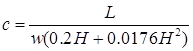

Cohesiometer Value, (c)

Where, L = Weight of shots in cm.

w = Diameter of width of specimen in cm

H = Height of specimen in cm

Stabilometer Resistance R-value

where, Pv = Vertical pressure applied (11.2 kg/cm2)

Ph = Horizontal pressure transmitted at Pv = 11.2 kg/cm2.

D2 = Displacement of stabilometer fluid necessary to increase the horizontal pressure from 0.35 to 7kg/cm2, measured in number of revolutions of the calibrated pump handle.

|

26 videos|91 docs|58 tests

|

FAQs on Highway Materials - Transportation Engineering - Civil Engineering (CE)

| 1. What are the different types of materials used in highway construction? |  |

| 2. What factors should be considered when selecting highway materials? |  |

| 3. How is the quality of highway materials evaluated? |  |

| 4. What are the challenges in using recycled materials for highway construction? |  |

| 5. How does climate affect the selection of highway materials? |  |

|

Explore Courses for Civil Engineering (CE) exam

|

|