Test: Utilization of Electrical Energy- 3 - Electrical Engineering (EE) MCQ

20 Questions MCQ Test - Test: Utilization of Electrical Energy- 3

The average speed of a train is independent of:

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Energy consumption in propelling the train is required for:

The least significant feature while selecting a motor for centrifugal pump is:

The load cycle for a motor driving a power press will be:

The luminous efficiency of a sodium vapour lamp is:

The fluorescent tube is coated form inside with a thin layer of fluorescent material in the form of powder in order to:

The light of fluorescent tube appears cooler than that from an incandescent lamp. This is due that fact that:

The electric resistance welding has the advantages of:

The basic electrical requirement in the arc welding is that there should be:

Hysteresis loss and eddy current loss are used in:

In induction heating, which of the following is of high value?

In an arc furnace, the choke is provided to:

Which is a process by which the purity of metal extracted from their ores can be improved?

The spongy coating of electroplating speaks of:

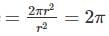

The solid angle subtended at the centre of a hemisphere of radius r will be: