Mechanical Engineering Exam > Mechanical Engineering Tests > Machine Design - 2 - Mechanical Engineering MCQ

Machine Design - 2 - Mechanical Engineering MCQ

Test Description

20 Questions MCQ Test - Machine Design - 2

Machine Design - 2 for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Machine Design - 2 questions and answers have been prepared

according to the Mechanical Engineering exam syllabus.The Machine Design - 2 MCQs are made for Mechanical Engineering 2024 Exam.

Find important definitions, questions, notes, meanings, examples, exercises, MCQs and online tests for Machine Design - 2 below.

Solutions of Machine Design - 2 questions in English are available as part of our course for Mechanical Engineering & Machine Design - 2 solutions in

Hindi for Mechanical Engineering course.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free. Attempt Machine Design - 2 | 20 questions in 12 minutes | Mock test for Mechanical Engineering preparation | Free important questions MCQ to study for Mechanical Engineering Exam | Download free PDF with solutions

Machine Design - 2 - Question 1

The important factor to be considered while selecting a bearing is

Detailed Solution for Machine Design - 2 - Question 1

Detailed Solution for Machine Design - 2 - Question 2

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Detailed Solution for Machine Design - 2 - Question 3

Detailed Solution for Machine Design - 2 - Question 4

Detailed Solution for Machine Design - 2 - Question 5

Machine Design - 2 - Question 6

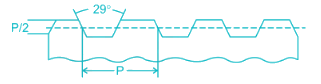

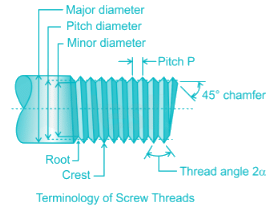

A double start thread has a pitch of 4 mm. The lead of the thread is

Detailed Solution for Machine Design - 2 - Question 6

Machine Design - 2 - Question 7

A key that has curved bottom to match the shaft. This key is known as________

Detailed Solution for Machine Design - 2 - Question 7

Detailed Solution for Machine Design - 2 - Question 8

Detailed Solution for Machine Design - 2 - Question 9

Machine Design - 2 - Question 10

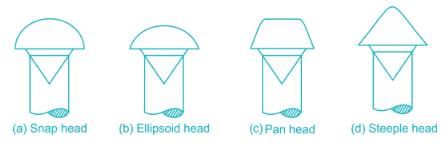

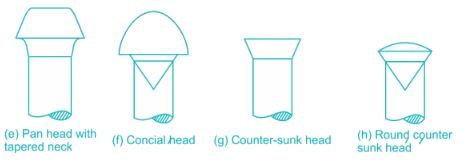

The head for boiler applications shown in the figure given below is:

Detailed Solution for Machine Design - 2 - Question 10

Machine Design - 2 - Question 12

Which if the following key is under compression rather than in being shear when under load?

Detailed Solution for Machine Design - 2 - Question 12

Detailed Solution for Machine Design - 2 - Question 13

Detailed Solution for Machine Design - 2 - Question 14

Detailed Solution for Machine Design - 2 - Question 15

Machine Design - 2 - Question 16

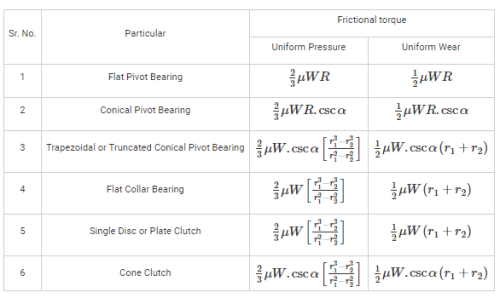

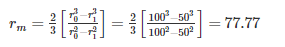

In a plate clutch axial force is 4 kN. The inside radius of contact surface is 50 mm and the outside radius is 100 mm. For uniform pressure the mean radius of friction surface will be

Detailed Solution for Machine Design - 2 - Question 16

Machine Design - 2 - Question 17

The centre to centre distance between two consecutive rivets in a row is called

Detailed Solution for Machine Design - 2 - Question 17

Detailed Solution for Machine Design - 2 - Question 18

Detailed Solution for Machine Design - 2 - Question 19

Machine Design - 2 - Question 20

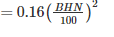

If for steel pinion BHN is 350 the value of load stress factor is

Detailed Solution for Machine Design - 2 - Question 20

Information about Machine Design - 2 Page

In this test you can find the Exam questions for Machine Design - 2 solved & explained in the simplest way possible.

Besides giving Questions and answers for Machine Design - 2, EduRev gives you an ample number of Online tests for practice

Download as PDF