Test: Properties of Metals, Simple Stress Strain & Elastic Constants - 2 - Civil Engineering (CE) MCQ

10 Questions MCQ Test - Test: Properties of Metals, Simple Stress Strain & Elastic Constants - 2

According to St. Venant’s principle

Notched bar tests are frequently used for testing the

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

In the creep test, the following type of stress is applied to the specimen

A free bar of length / is uniformly heated from 0°C to a temperature t°C, α is the coefficient of linear expansion and E is the modulus of elasticity. The stress in the bar is

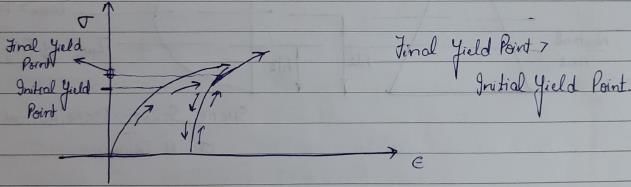

A test specimen is stressed slightly beyond the yield point and then unloaded. Its yield strength

Cup-and-cone type fracture occurs in the case of

Materials having elongation less than 5% are considered brittle. In such cases, factor of safety is based on

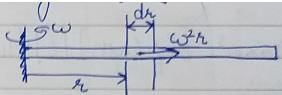

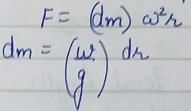

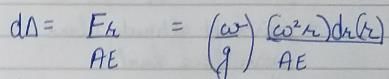

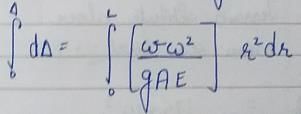

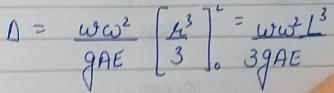

A rod of length 'l’ and cross-sectional area ‘A’ rotates about an axis passing through one end of the rod. The extension produced in the rod due to centrifugal forces is (w is the weight of the rod per unit length and ω is the angular velocily of rotation of the rod)

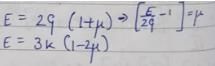

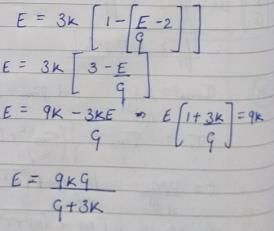

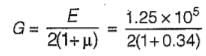

Young’s modulus of elasticity and Poisson’s ratio of a material are 1.25 x 105 MPa and 0.34 respectively. The modulus of rigidity of the material is

In a homogeneous, isotropic elastic material, the modulus of elasticity E in terms of G and K is equal to

= 0.4664 x 105 MPa

= 0.4664 x 105 MPa