Past Year Questions: Metal Forming - Mechanical Engineering MCQ

30 Questions MCQ Test - Past Year Questions: Metal Forming

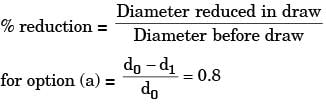

A wire of 0.1 mm dia is drawn from a rod of 15 mm diameter dies giving reductions of 20%, 40% and 80% are available. For minimum error in the final size, the number of stages and reduction at each stage respectively would be

[ME 1996]

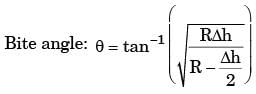

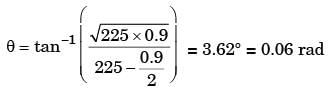

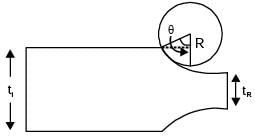

A strip with cross-sectional area 150 mm × 4.5 mm is being rolled with 20% reduction of area using 450 mm diameter rollers. The angle subtended by the deformation zone at the roll centre is (in radians)

[ME 1998]

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Hot rolling of mild steel is carried out

[ME 2002]

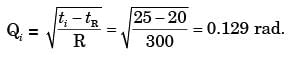

In a rolling process, sheet of 25 mm thickness is rolled to 20 mm thickness. Roll is of diameter 600 mm and it rotates at 100 rpm. The roll strip contact length will be

[ME 2004]

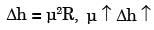

A 4 mm thick sheet is rolled with 300 mm diameter rolls to reduce thickness without any change in its width. The friction coefficient at the work-roll interface is 0.1. The minimum possible thickness of the sheet that can be produced in a- single pass is

[ME 2006]

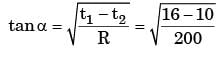

The thickness of a metallic sheet is reduced from an initial value of 16 mm to a final value of 10 mm in one single pass rolling with a pair of cylindrical rollers each of diameter of 400 mm. The bite angle in degree will be

[ME 2007]

The maximum possible draft in cold rolling of sheet increases with the

[ME 2011]

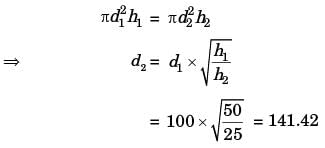

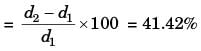

A solid cylinder of diameter 100 mm and height 50 mm is forged between two frictionless flat dies to a height of 25 mm. The percentage change in diameter is

[ME 2012]

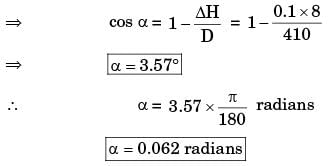

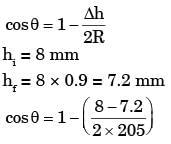

In a single pass rolling process using 410 mm diameter steel rollers, a strip of width 140 mm and thickness 8 mm undergoes 10% reduction of thickness. The angle of bite in radians is

[ME 2012]

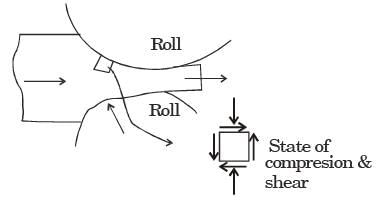

In a rolling process, the state of stress of the material undergoing deformation is

[ME 2013]

With respect to metal working, match Group A with Group B:

Group A

P. Defect in extrusion

Q. Defect in rolling

R. Product of skew rolling

S. Product of rolling through cluster mill

Group B

I. alligatoring

II. scab

III.fish tail

IV. seamless tube

V. thin sheet with tight tolerance

VI. semi-finished balls of ball bearing

[ME 2014,Set-2]

The cold forming process in which a hardened tool is pressed against a workpiece (when there is relative motion between the tool and the workpiece) to produce a roughened surface with a regular pattern is

[ME 2019,Set-2]

The blank diameter used in thread rolling will be

[PI 1989]

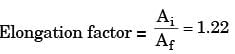

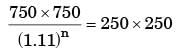

If the elongation factor during rolling of an ingot is 1.22. The minimum number of passes needed to produce a section 250 x 250 mm from an ingot of 750 × 750 mm are

[PI 1992]

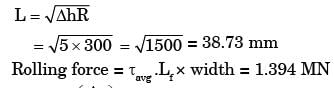

A copper strip of 200 mm width and 300 mm thickness is to be rolled to a thickness of 295 mm. The roll of radius 300 mm rotates at 100 rpm. The average shear strength of the work material is 180 MPa. The roll strip contact length and the roll force are

[PI 2006]

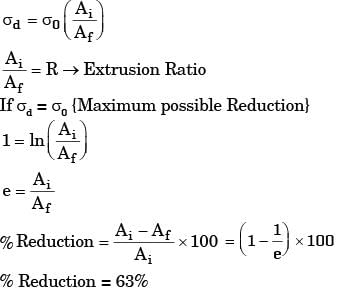

The maximum possible percentage reduction in area per pass during wire drawing of an ideal plastic material without friction is of the order of

[PI 2007]

In a rolling process, thickness of a strip is reduced from 4 mm to 3 mm using 300 mm diameter rolls rotating at 100 rpm. The velocity of the strip (in m/sec) at the neutral point is

[PI 2008]

Anisotropy in rolled components is caused by

[PI 2009]

In a rolling process, the roll separating force can be decreased by

[PI 2010]

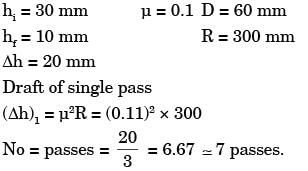

The thickness of a plate is reduced from 30 mm to 10 mm by successive cold rolling passes using identical rolls of diameter 600 mm. Assume that there is no change in width. If the coefficient of friction between the rolls and the workpiece is 0.1, the minimum number of passes required is

[PI 2011]

In a single pass rolling process using 410 mm diameter steel rollers, a strip of width 140 mm and thickness 8 mm undergoes 10% reduction of thickness. The angle of bite in radians is

[PI 2012]

In a rolling process, the state of stress of the material undergoing deformation is

[PI 2013]

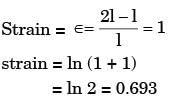

The true sliding strain for a low carbon Steel bar which is doubled in length by forging is

[ME 1992]

A test specimen is stressed slightly beyond the yield point and then unloaded. Its yield strength

[ME 1995]

Ductility of material with work hardening

[ME 2002]

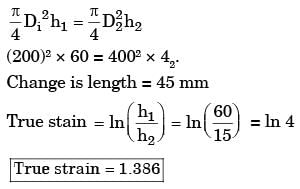

A 2 mm thick metal sheet is to be bent at an angle of one radian with a bend radius of 100 mm. If the stretch factor is 0.5, the bend allowance is

[ME 2005]

In open-die forging, a disc of diameter 200 mm and height 60 mm is compressed without any barreling effect. The final diameter of the disc is 400 mm. The true strain is

[ME 2007]

The force requirement in a blanking operation of low carbon steel sheet is 5.0 kN. The thickness of the sheet is 't' and diameter of the blanked part is 'd'. For the same work material, if the diameter of the blanked part is increased to 1.5d and thickness is reduced to 0.4t, the new blanking force in kN is

[ME 2007]

The operation in which oil is permeated into the pores of a powder metallurgy product is known as

[ME 2011]