Past Year Questions: Joining/Welding - Mechanical Engineering MCQ

30 Questions MCQ Test - Past Year Questions: Joining/Welding

For gas welding a particular job using a neutral oxyacetylene flame the acetylene consumption was 10 litres. The oxygen consumption from the cylinder in liters will be

[ME 1991]

For butt welding 40 mm thick steel plates, when the expected quantity of such jobs is 5000 per month over a period of 10 years, choose the best suitable welding process out of the following available alternatives.

[ME 1999]

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

The temperature of a carburizing flame in gas welding that of a neutral or an oxidizing flame

[ME 2002]

In welding a mild steel sheet using an oxyacetylene flame, the total amount of acetylene consumed was 8.0 litres, the oxygen consumption from the cylinder is

[PI 1989]

During gas welding of copper sheets a neutral flame was used consuming 8 litres of acetylene.But the weld was found to be defective. So it was rewelded using an oxidizing flame. The likely consumption of oxygen in litres will be

[PI 1993]

Which of the following powders should be fed for effective oxy-fuel cutting of stainless steel.

[PI 2001]

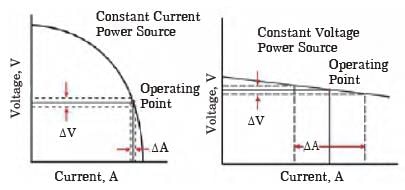

At small variations of arc length at operating conditions, the manual metal arc welding transformer provides nearly

[ME 1990]

In DC welding, the straight polarity (electrode negative) results in

[ME 1993]

The electrodes used in arc welding are coated.This is not expected to

[ME 1994]

Preheating before welding is done to

[ME 1996]

Two plates of the same metal having equal thickness are to be butt welded with electric arc.When the plate thickness changes, welding is achieved by

[ME 2002]

Which of the following arc welding processes does not use consumable electrode

[ME 2002]

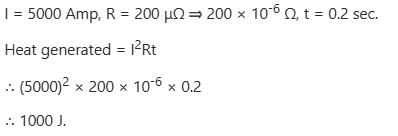

Two 1 mm thick steel sheets are to be spot welded at a current of 5000 A. Assuming effective resistance to be 200 micro-ohms and current flow time of 0.2 second, heat generated during the process will be

[ME 2004]

In an arc welding process, the voltage and current are 25 V and 300 A respectively. The arc heat transfer efficiency is 0.85 and welding speed is 8 mm/s. The net heat input (in J/mm) is

[ME 2006]

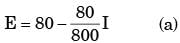

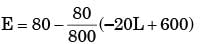

A direct current welding machine with a linear power source characteristic provides open circuit voltage of 80 V and short circuit current of 800 A. During welding with the machine, the measured arc current is 500 A corresponding to an arc length of 5.0 mm and the measured arc current is 460 A corresponding to an arc length of 7.0 mm.

The linear voltage (E) - arc length (L) characteristic of the welding arc can be given as (where E is in Voit and L is in mm)

[ME 2007]

In arc welding of a butt joint, the welding speed is to be selected such that highest cooling rate is achieved. Melting efficiency and heat transfer efficiency are 0.5 and 0.7, respectively. The area of the weld cross section is 5 mm2 and the unit energy required to melt the metal is 10 J/mm3.If the welding power is 2 kW, the welding speed in mm/s is closest to

[ME 2008]

Which one among the following welding processes uses non-consumable electrode?

[ME 2011]

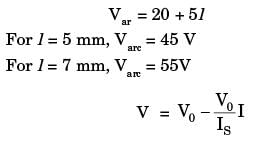

In a DC arc welding operation, the voltage-arc length characteristic was obtained as Varc = 20 + 5l where the arc length l was varied between 5 mm and 7 mm. Here Varc denotes the arc voltage in Volts. The arc current was varied from 400 A to 500 A. Assuming linear power source characteristic, the open circuit voltage and the short circuit current for the welding operation are

[ME 2012]

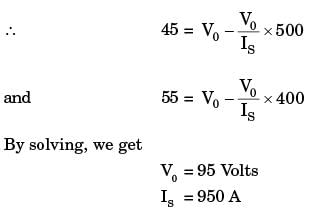

In a linear arc welding process, the heat input per unit length is inversely proportional to

[ME 2015,Set-1]

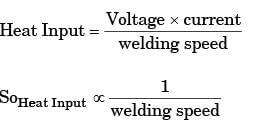

During a TIG welding process, the arc current and arc voltage were 50 A and 60 V, respectively, when the welding speed was 150 mm/min. In another process, the TIG welding is carried out at a welding speed of 120 mm/min at the same arc voltage and heat input to the material so that weld quality remains the same. The welding current (in A) for this process is ___________ .

[ME 2015,Set-2]

The welding process which uses a blanket of fusible granular flux is

[ME 2016,Set-2]

In an arc welding process, welding speed is doubled. Assuming all other process parameters to be constant, the cross sectional area of the weld bead will

[ME 2017,Set-1]

The mode of metal transfer in CO2-MIG welding at low temperature is

[PI 1990]

High alloy steel components are preheated before welding for reducing

[PI 1991]

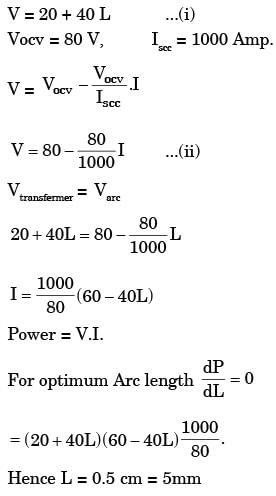

The voltage arc length characteristics of a DC arc is given by V = 20 + 40L, where L = arc length in cm. The power source characteristics can be approximated by a straight line. Open circuit is 80 V and short circuit current 1000 Amps. The optimum arc length in mm

[PI 1991]

Which of the following process can be used for welding of Aluminum alloys?

P. Submerged arc welding

Q. Gas metal arc welding

R. Electroslag welding

S. Gas tungsten arc welding

[PI 2003]

The current in Amperes used in resistance spot welding of plain carbon steel sheets (1 to 3 mm thick) lies within the range

[PI 2004]

The DC power source for arc welding has the characteristic 3V + I = 240, where V = Voltage and I = Current in amp. For maximum are power at the electrode, voltage should be set at

[PI 2007]

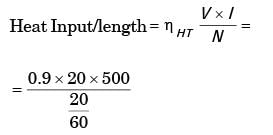

Autogeneous gas tungsten arc welding of a steel plate is carried out with welding current of 500 A. Voltage of 20 V and weld speed of 20 mm/ min. Consider the heat transfer efficiency from the arc to the weld pool as 90%. The heat input per unit length (in kJ/mm) is

[PI 2009]