Past Year Questions: Machining And Machine Tool Operation - Mechanical Engineering MCQ

30 Questions MCQ Test - Past Year Questions: Machining And Machine Tool Operation

The size of BUE in metal cutting increases with

[ME 1989]

Crater wear always starts at some distance from the tool tip because at that point

[ME 1989]

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Most of the metal cutting heat goes into the

[ME 1990]

In comparison to HSS, super HS contains higher percentage of

[ME 1990]

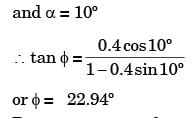

In a typical metal cutting operation, using a cutting tool a positive rake a = 10°, it is as observed that the shear angle was 20°. The friction angle is

[ME 1997]

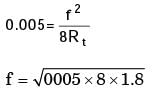

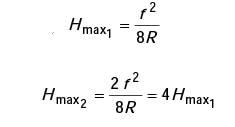

A cutting tool has a nose radius of 1.8 mm the feed rate for a theoretical surface roughness of Rt = 5 microns is

[ME 1997]

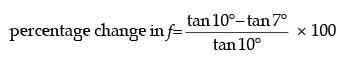

What is the approximate % change in the life, f, of the tool with zero rake angle used in orthogonal cutting when its clearance angle, α, is changed from 10 to 7 deg?

(Hint : Flank wear rate is proportional to cot a)

[ME 1999]

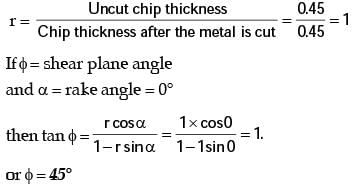

In orthogonal machining operation, the chip thickness and the uncut chip thickness are equal to 0.45 mm. If the tool rake and is 0 deg. The shear plane angle is

[ME 1998]

A built up edge is formed while machining

[ME 2000]

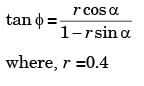

During orthogonal cutting of MS with a 10 deg rake angle tool, the chip thickness ratio was obtained as 0.4. The shear angle (in degrees) evaluated from this data is

[ME 20017]

Friction at the tool-chip interface can be reduced by

[ME 2009]

Minimum shear-strain in orthogonal turning with a cutting tool of zero rake angle is

[ME 2009]

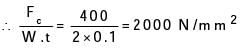

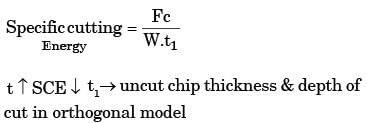

The main cutting force acting on a tool during the turning (orthogonal cutting) operation of a metal is 400 N. The turning was performed using 2 mm depth of cut and 0.1 mm/rev feed rate.

The specific cutting pressure (in N/mm2) is

[ME 2014,Set-1]

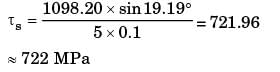

In orthogonal turning of a cylindrical tube of wall thickness 5 mm, the axial and the tangential cutting forces were measured at 1259 N and 1601 N, respectively. The measured chip thickness after machining was found to be 0.3 mm. The rake angle was 10° and the axial feed was 100 mm/min. The rotational speed of the spindle was 1000 rpm. Assuming the material to be perfectly plastic and merchant’s first solution, the shear strength of the martial is closest to

[ME 2019,Set-1]

Assertion (A): A diamond tool is used for USM of glass workpiece.

Reason (R): Diamond is harder than glass

[PI 1990]

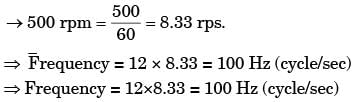

The diameter and rotational speed of a job are 100 m and 500 rpm respectively. The high spots (chatter marks) are found at a spacing of 30 deg on the job surface. The chatter frequency is

[PI 1990]

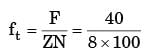

A milling cutter having 8 teeth is rotating at 100 rpm. The workpiece feed is set at 40 mm/ min the feed per tooth is

[PI 1990]

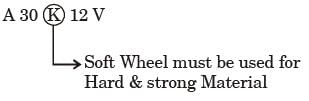

The base of a brass bracket has to be rough ground to remove the unevenness. The 4 wheels available in the store. The appropriate wheel is

[PI 1990]

Only negative rake angles are used with the following tool material

[PI 1994]

In metal cutting BUE formation results in

[PI 1994]

The heat generated in metal cutting is dissipated in different proportions into environment, tool, chip and workpiece. The correct order of this proportion in decreasing magnitude is (no cutting fluid is used)

[PI 1994]

Hot hardness in an essential property for

[PI 1995]

In HSS tool materials the element tungsten can be completely replaced, without changing the material property by

[PI 1995]

When the depth of cut in increased, the specific cutting energy

[PI 1995]

The material most commonly used for manufacturing of machine tool beds is.

[PI 1995]

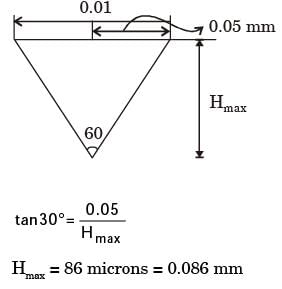

A 60 deg symmetrical V tool is used in shaping at workpiece with a depth of cut of 0.1 mm and feed of 0.1 mm/stroke. The theoretical peak to valley height, in mm, of the surface produced is

[PI 1995]

A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of

[PI 2003]

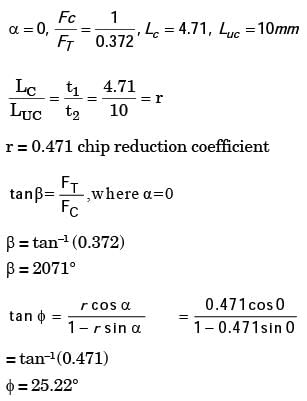

Orthogonal machining of a steel workpiece is done with a HSS tool of zero rake angle. The ratio of the cutting force and the thrust force on the tool is 1 : 0.372. The length of cut chip is 4.71 mm while the uncut chip length is 10 mm.What is the shear plane angle ϕ and friction angle β in degree? Use Merchants theory

[PI 2003]

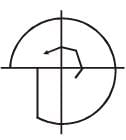

A job of the shape shown in the figure below is to be machined on a lathe. The tool best suited for machining of this job must have

[PI 2004]

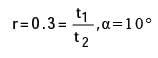

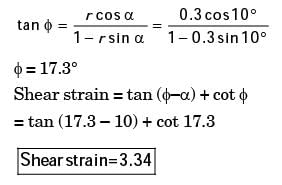

In a machining operation chip thickness ratio is 0.3 and the back rake angle of the tool is 10°.What is the value of the shear strain?

[PI 2005]