Test: Conduction Level - 3 - Mechanical Engineering MCQ

20 Questions MCQ Test - Test: Conduction Level - 3

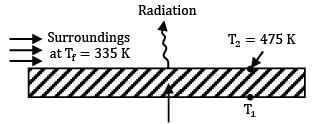

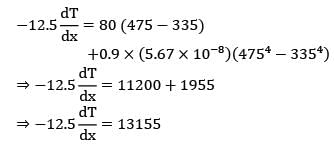

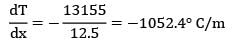

A surface at 475 K convects and radiates heat to the surroundings at 335 K. If the surface conducts this heat through a solid plate of thermal conductivity 12.5 W/m-°C, determine the temperature gradient at the surface in the solid. Take convective coefficient and emissivity as 80 W/m2-°C and 0.9 respectively

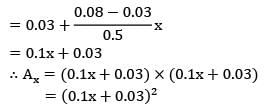

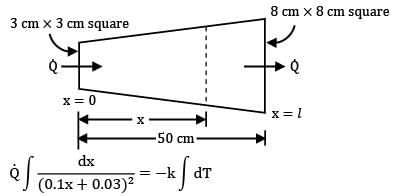

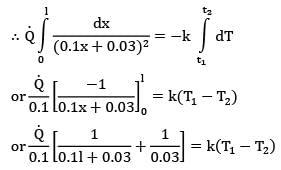

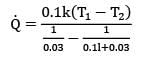

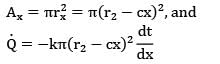

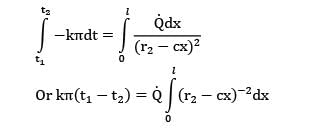

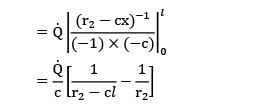

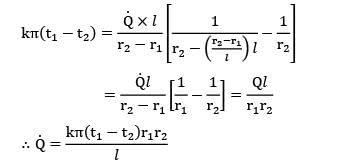

Heat is conducted through a uniformly tapered rod of square cross-section and length 50 cm. At the left end, the side of face is 3 cm and the temperature is 600°C. At the right end, the corresponding values are 8 cm and 150°C. Determine the rate of heat conduction. It may be presumed that thermal conductivity of the material of rod is 60 W/mK and heat is conducted only along the length of rod.

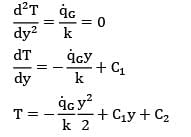

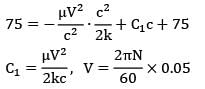

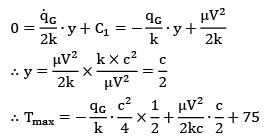

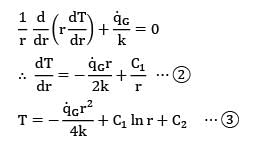

An oil film acts as a lubricant (? = 10 N-s/m2, k = 230 W/m-K,? = 1200 kg/m3) between two coaxial cylindrical surfaces (outer diameter and inner diameter = 99.5 mm). The outer cylinder rotates at . Calculate the maximum temperature in the oil film if both wall temperatures are maintained at 75°C. The rate of heat generation per unit volume due to viscous dissipation may be assumed to be  . As the oil layer is very thin ignore any convection in the layer.

. As the oil layer is very thin ignore any convection in the layer.

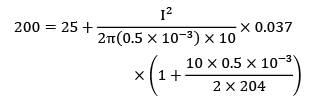

A 1 mm dia aluminium (k = 204 W/m-K) wire can carry a current till wire temperature does not exceed Tmax = 200°C when suspended in air at 25°C where h = 10 W/m2K. For the wire, the specific resistance is 0.037 ohm/m. The maximum current the wire can carry is __________A.

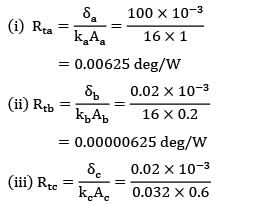

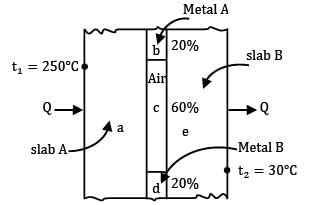

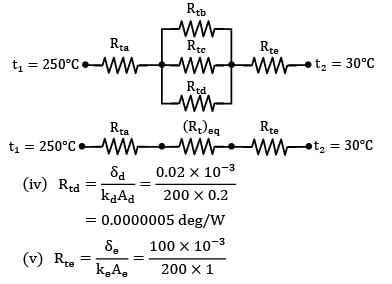

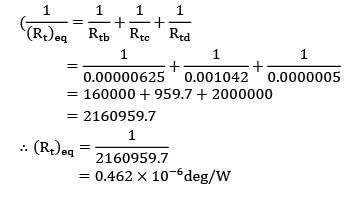

Two slabs, each 100 mm thick and made of materials with thermal conductivities of 16 W/m-deg and 1600 W/m-°C, are placed in contact which is not perfect. Due to roughness of surfaces, only 40% of the area is in contact and air fills 0.02 mm thick gaps in the remaining area. If the extreme surfaces of the arrangement are at temperatures of 250°C and 30°C, determine the heat flow rate through the composite system.

Take thermal conductivity of air as 0.032 W/m-°C and assume that half of the contact (of the contact area) is due to either metal.

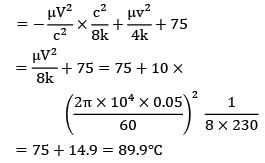

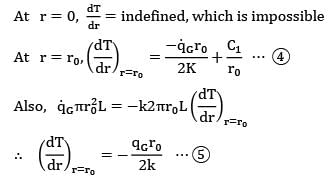

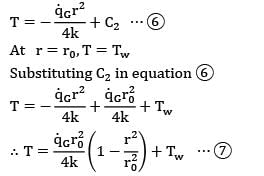

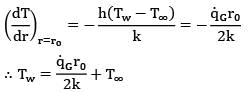

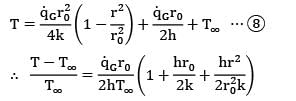

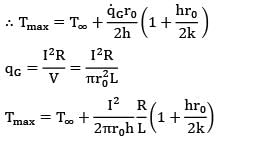

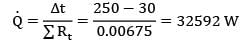

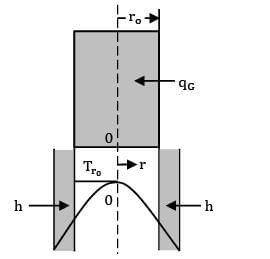

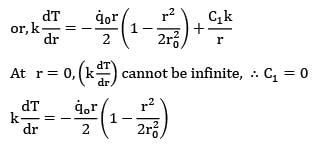

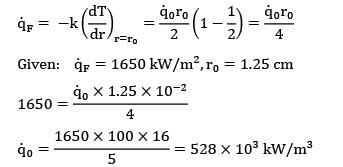

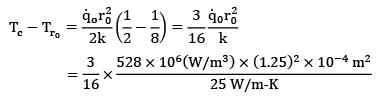

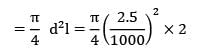

In a cylindrical fuel rod of a nuclear reactor, heat is generated internally according to the equation![]() where

where ![]() is the local rate of heat generation per unit volume at radius r,r0 is the outside radius, and

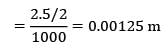

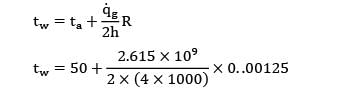

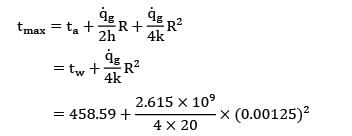

is the local rate of heat generation per unit volume at radius r,r0 is the outside radius, and ![]() is the rate of heat generation per unit volume at the centre line. Calculate the temperature drop from the centre line to the surface for a 2.5 cm outer diameter rod having k = 20 W/m-K, if the rate of heat removal from the surface is 1650 kW/m2.

is the rate of heat generation per unit volume at the centre line. Calculate the temperature drop from the centre line to the surface for a 2.5 cm outer diameter rod having k = 20 W/m-K, if the rate of heat removal from the surface is 1650 kW/m2.

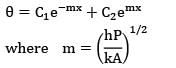

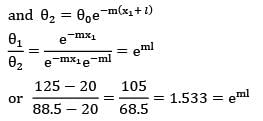

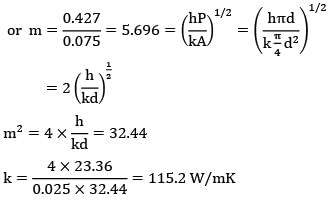

One end of a long rod is inserted into a furnace while the other projects into ambient air. Under steady state the temperature of the rod is measured at two points 75 mm apart and found to be 125°C and 88.5°C.respectively, while the ambient temperature is 20°C. If the rod is 25 mm in diameter and h is 23.36 W/m2-K, find the thermal conductivity of the rod material.

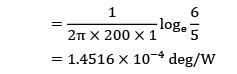

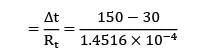

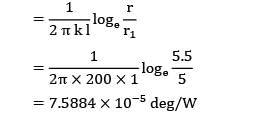

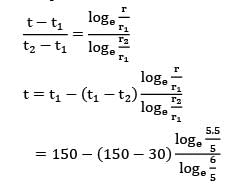

Hot combustion gases at 150°C flow through a hollow cylindrical pipe of 10 cm inner diameter and 12 cm outer diameter. The pipe is located in a space at 30°C and the thermal conductivity of the pipe material is 200 W/m-K. Neglecting surface heat transfer coefficients, calculate the temperature at a point halfway between the inner and outer surface.

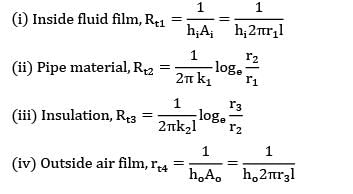

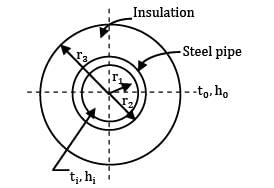

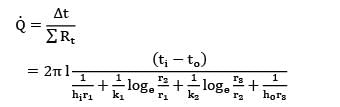

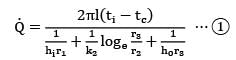

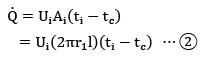

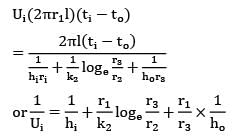

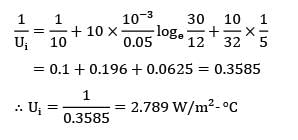

A steel pipe of 20 mm inner diameter and 2 mm thickness is covered with 20 mm thick fiberglass insulation(k = 0.05 W/m-°C). If the inside and outside convective coefficients are 10 W/m2-°C and 5W/m2-°C , calculate the overall heat transfer coefficient based on inside diameter of the pipe.

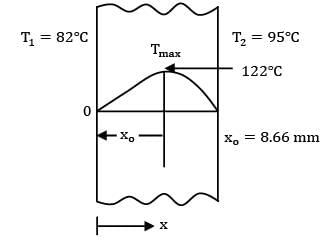

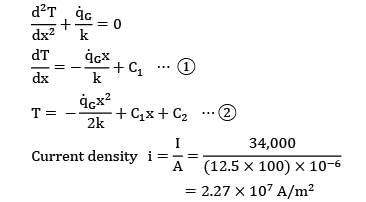

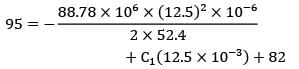

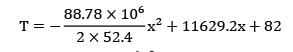

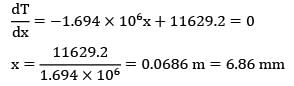

An electric current of 34,000 A flows along a flat steel plate 12.5 mm thick and 100 mm wide. The temperature of one surface of the plate is 82°C and that of the other is 95°C and the value of the maximum temperature.

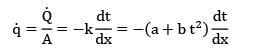

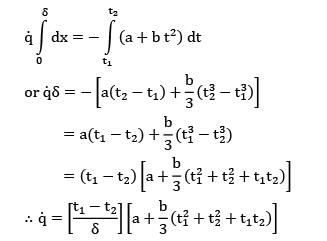

For a furnace wall of thickness the thermal conductivity varies with temperature according to the relation

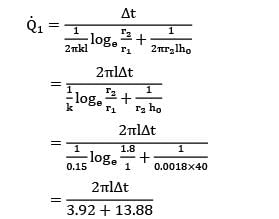

k = (a+bt2)W/m-°C where t is in °C Proceed to calculate the rate of heat transfer through the wall if ? = 0.25 m, t1 = 250°C, t2 = 25°C, a = 0.3 & b = 5 X 10-6 in W/m2

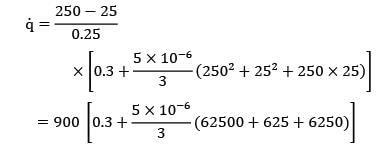

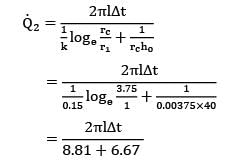

A 2 mm diameter wire with 0.8 mm thick layer of insulation (k = 0.15 W/m-°C) is used in a certain electric heating application. The insulation surface is exposed to the atmosphere with convective heat transfer coefficient 40 W/m2-°C. What percentage change in heat transfer rate would occur if critical thickness of insulation is used? It may be assumed that temperature difference between surface of the wire and surrounding air remains unchanged

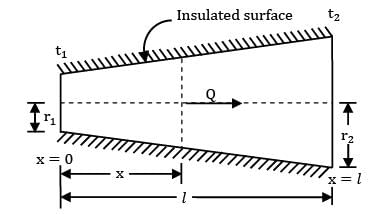

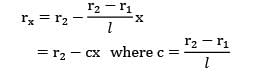

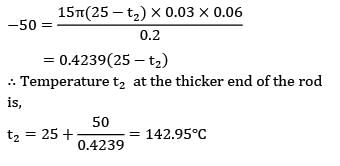

A tapered stainless steel rod, perfectly insulated on the curved surface, has end diameters of 6 cm and 12 cm respectively, and is 20 cm long. The thicker end is fixed to a hot wall and the thinner end is maintained at 25°C. The steady state rate of heat loss through the rod is estimated to be 50W. Calculate the temperature at the hot end of the rod. Take thermal conductivity of the rod material as 15 W/m-°C

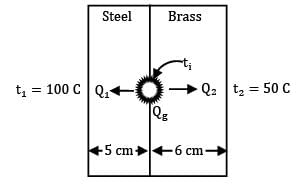

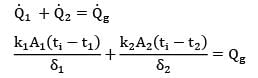

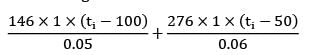

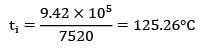

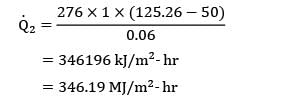

A composite slab consists of a 5 cm thick layer of steel (k = 146 kJ/m-hr-°C) on the left side and a 6 cm thick layer of brass (k = 276 kJ/m-hr-°C) on the right hand side. The outer surfaces of the steel and brass layer are maintained at 100°C and 50°C respectively. The contact between the two slabs is perfect and heat is generated at the rate of 4.2 X 105kJ/m2-hr at the plane of contact. The heat thus generated is dissipated from both sides of composite slab for steady state conditions to calculate heat flow rate through steel and brass slab respectively in MJ/m2-hr.

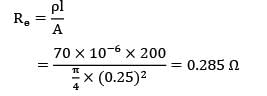

A stainless steel wire (thermal conductivity = 20 W/m2°C) & resistivity = 70 micro ohm-cm) of length 2 m and diameter 2.5 mm is submerged in a fluid 50°C at and an electric current of intensity 300 amps passes through it. If heat convection coefficient at the wire surface is 4 kW/m2°C, workout the steady state temperature at the center.

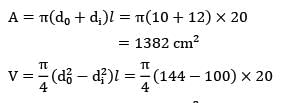

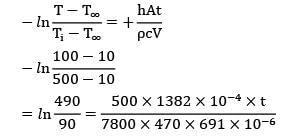

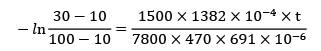

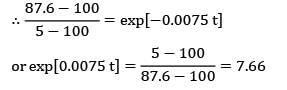

A steel tube of length 20 cm with internal and external diameters of 10 and 12 cm is quenched from 500°C to 30°C in a large reservoir of water at 10°C. Below 100°C the heat transfer coefficient is 1.5 kW/m2K. Above 100°C it is less owing to a film of vapour being produced at the surface, and an effective mean value between 500°C & 100°C is 0.5 kW/m2K.The density of steel is 7500 kg/m3 and the specific heat is 0.47 kJ/kg-K. Neglecting internal thermal resistance of the steel tube, determine the quenching time.

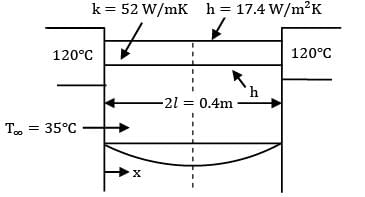

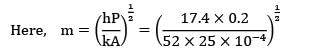

A 50 mm X 50 mm iron bar 0.4 m long is connected to the walls of two heated reservoirs, each at 120°C. The ambient air temperature is 35°C and the convective heat transfer coefficient is 17.4 W/m2-K. Calculate the rate of heat loss from the bar. The thermal conductivity of iron is 52W/m-K.

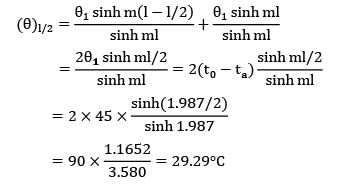

A copper rod (k = 0.15 W/m-°C) is 12 mm in diameter and spans between two plates 150 mm apart. Air flows over the plates providing convective heat transfer coefficient equal to 50 W/m2-°C. If surface temperature of the plates exceeds the air temperature by 45°C, calculate excess temperature at mid length of the rod over that of air. The temperature within the rod varies only along its length.

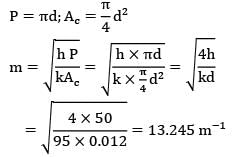

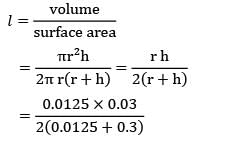

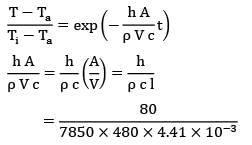

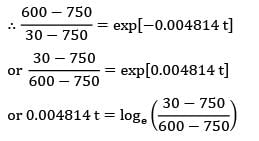

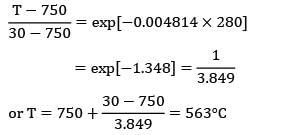

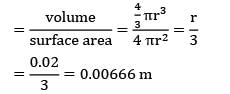

During heat treatment, cylindrical pieces of 25 mm diameter, 30 mm height and at 30°C are placed in a furnace at 750°C with convection coefficient 80 W/m2-°C. It is required to heat the pieces to 600°C before pieces are taken out. What will be the shortfall in temperature if the pieces are taken out from the furnace after 280 seconds? Assume the following property values:

Density 7850 kg/m3 ; specific heat 480 J/kg-K; Conductivity 40 W/m-°C

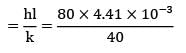

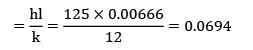

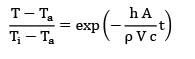

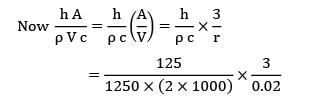

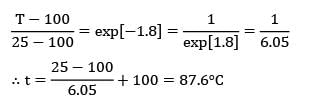

An egg with a mean diameter of 4 cm and initially at 25°C is placed in a boiling water pan for 4 minutes and found to be boiled to the consumer’s taste. For how long (in seconds) should a similar egg for the same consumer be boiled when taken from a refrigerator at 5°C? Use lumped parameter theory and presume the following properties for egg

k = 12 W/m-°C

h = 125 W/m2-°C

c = 2kJ/kg-K

And ? = 1250 kg/m3