Case Based Questions Test: Mechanical Properties of Solids - ACT MCQ

10 Questions MCQ Test - Case Based Questions Test: Mechanical Properties of Solids

Attempt All Questions sub parts from each question.

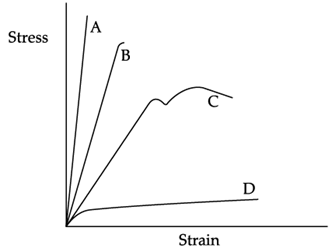

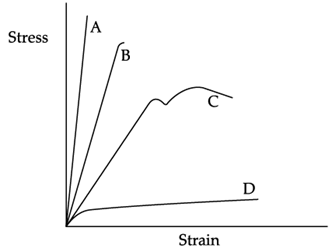

Elasticity vs. plasticity: Objects get deformed when pushed, pulled, and twisted. Elasticity is the measure of the amount that the object can return to its original shape after these external forces and pressure are removed. The opposite of elasticity is plasticity. When something is stretched, and it stays stretched, the material is said to be plastic. Such deformation is said to be plastic deformation. In elastic deformation, atoms of the material are displaced temporarily from their original lattice site. They return back to their original position after the removal of external force. In plastic deformation, atoms of the solid are displaced permanently from their original lattice site. They don’t return back to the original position even after the removal of external load. So, elastic deformation is temporary, whereas plastic deformation is permanent. Amount of elastic deformation is very small. But the amount of plastic deformation is quite large. External force required for elastic deformation of solid is quite small. Force required for plastic deformation is much higher. Total energy absorbed by the material during elastic and plastic deformation region is called modulus of toughness. Energy absorbed by the material during elastic deformation is called module of resilience. Most materials have an amount of force or pressure for which they deform elastically. If more force or pressure is applied, then they undergo plastic deformation. Materials those have a fair amount of plastic deformation before breaking are said to be ductile. Materials those can't stretch or bend much without breaking are said to be brittle. Copper, aluminium etc. are ductile materials. For this reason those are used for making wires. Glass and ceramics are often brittle; they will not bend; they will break.

Q. Which of the following statement is false?

Attempt All Questions sub parts from each question.

Elasticity vs. plasticity: Objects get deformed when pushed, pulled, and twisted. Elasticity is the measure of the amount that the object can return to its original shape after these external forces and pressure are removed. The opposite of elasticity is plasticity. When something is stretched, and it stays stretched, the material is said to be plastic. Such deformation is said to be plastic deformation. In elastic deformation, atoms of the material are displaced temporarily from their original lattice site. They return back to their original position after the removal of external force. In plastic deformation, atoms of the solid are displaced permanently from their original lattice site. They don’t return back to the original position even after the removal of external load. So, elastic deformation is temporary, whereas plastic deformation is permanent. Amount of elastic deformation is very small. But the amount of plastic deformation is quite large. External force required for elastic deformation of solid is quite small. Force required for plastic deformation is much higher. Total energy absorbed by the material during elastic and plastic deformation region is called modulus of toughness. Energy absorbed by the material during elastic deformation is called module of resilience. Most materials have an amount of force or pressure for which they deform elastically. If more force or pressure is applied, then they undergo plastic deformation. Materials those have a fair amount of plastic deformation before breaking are said to be ductile. Materials those can't stretch or bend much without breaking are said to be brittle. Copper, aluminium etc. are ductile materials. For this reason those are used for making wires. Glass and ceramics are often brittle; they will not bend; they will break.

Q. Aluminium is a ............... materials.

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Attempt All Questions sub parts from each question.

Elasticity vs. plasticity: Objects get deformed when pushed, pulled, and twisted. Elasticity is the measure of the amount that the object can return to its original shape after these external forces and pressure are removed. The opposite of elasticity is plasticity. When something is stretched, and it stays stretched, the material is said to be plastic. Such deformation is said to be plastic deformation. In elastic deformation, atoms of the material are displaced temporarily from their original lattice site. They return back to their original position after the removal of external force. In plastic deformation, atoms of the solid are displaced permanently from their original lattice site. They don’t return back to the original position even after the removal of external load. So, elastic deformation is temporary, whereas plastic deformation is permanent. Amount of elastic deformation is very small. But the amount of plastic deformation is quite large. External force required for elastic deformation of solid is quite small. Force required for plastic deformation is much higher. Total energy absorbed by the material during elastic and plastic deformation region is called modulus of toughness. Energy absorbed by the material during elastic deformation is called module of resilience. Most materials have an amount of force or pressure for which they deform elastically. If more force or pressure is applied, then they undergo plastic deformation. Materials those have a fair amount of plastic deformation before breaking are said to be ductile. Materials those can't stretch or bend much without breaking are said to be brittle. Copper, aluminium etc. are ductile materials. For this reason those are used for making wires. Glass and ceramics are often brittle; they will not bend; they will break.

Q. Which of the following 4 stress-strain graphs represent a ductile material and a brittle material?

Attempt All Questions sub parts from each question.

Elasticity vs. plasticity: Objects get deformed when pushed, pulled, and twisted. Elasticity is the measure of the amount that the object can return to its original shape after these external forces and pressure are removed. The opposite of elasticity is plasticity. When something is stretched, and it stays stretched, the material is said to be plastic. Such deformation is said to be plastic deformation. In elastic deformation, atoms of the material are displaced temporarily from their original lattice site. They return back to their original position after the removal of external force. In plastic deformation, atoms of the solid are displaced permanently from their original lattice site. They don’t return back to the original position even after the removal of external load. So, elastic deformation is temporary, whereas plastic deformation is permanent. Amount of elastic deformation is very small. But the amount of plastic deformation is quite large. External force required for elastic deformation of solid is quite small. Force required for plastic deformation is much higher. Total energy absorbed by the material during elastic and plastic deformation region is called modulus of toughness. Energy absorbed by the material during elastic deformation is called module of resilience. Most materials have an amount of force or pressure for which they deform elastically. If more force or pressure is applied, then they undergo plastic deformation. Materials those have a fair amount of plastic deformation before breaking are said to be ductile. Materials those can't stretch or bend much without breaking are said to be brittle. Copper, aluminium etc. are ductile materials. For this reason those are used for making wires. Glass and ceramics are often brittle; they will not bend; they will break.

Q. Hooks law is applicable for

Attempt All Questions sub parts from each question.

Elasticity vs. plasticity: Objects get deformed when pushed, pulled, and twisted. Elasticity is the measure of the amount that the object can return to its original shape after these external forces and pressure are removed. The opposite of elasticity is plasticity. When something is stretched, and it stays stretched, the material is said to be plastic. Such deformation is said to be plastic deformation. In elastic deformation, atoms of the material are displaced temporarily from their original lattice site. They return back to their original position after the removal of external force. In plastic deformation, atoms of the solid are displaced permanently from their original lattice site. They don’t return back to the original position even after the removal of external load. So, elastic deformation is temporary, whereas plastic deformation is permanent. Amount of elastic deformation is very small. But the amount of plastic deformation is quite large. External force required for elastic deformation of solid is quite small. Force required for plastic deformation is much higher. Total energy absorbed by the material during elastic and plastic deformation region is called modulus of toughness. Energy absorbed by the material during elastic deformation is called module of resilience. Most materials have an amount of force or pressure for which they deform elastically. If more force or pressure is applied, then they undergo plastic deformation. Materials those have a fair amount of plastic deformation before breaking are said to be ductile. Materials those can't stretch or bend much without breaking are said to be brittle. Copper, aluminium etc. are ductile materials. For this reason those are used for making wires. Glass and ceramics are often brittle; they will not bend; they will break.

Q. Ceramic is a ............... material

Attempt All Questions sub parts from each question.

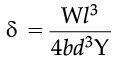

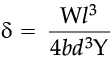

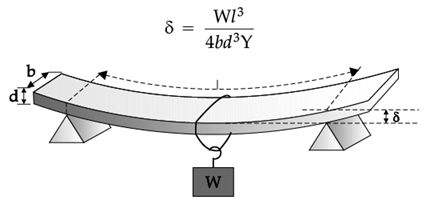

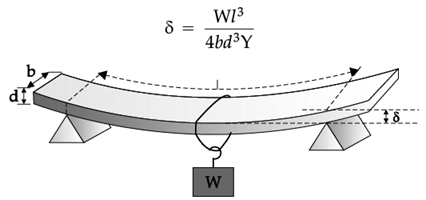

Sagging of a bridge A bridge is designed such that it can withstand the load of the flowing traffic, the force of winds and its own weight. Let us consider the case of a beam loaded at the centre and supported near its ends as shown in Figure. A beam of length l, breadth b, and depth d when loaded at the centre by a load W sags by an amount given by

From the equation, we see that to reduce the bending for a given load, one should use a material with a large Young’s modulus Y. For a given material, increasing the depth d rather than the breadth b is more effective in reducing the bending, since δ is proportional to d–3 and to b–1 (of course the length l of the span should be as small as possible).

Amongst bridge materials steel has the highest and most favorable strength qualities, and it is therefore suitable for the most daring bridges with the longest spans. Normal building steel has compressive and tensile strengths of 370 N/sq mm, about ten times the compressive strength of a medium concrete and a hundred times its tensile strength. A special merit of steel is its ductility due to which it deforms considerably before it breaks, because it begins to yield above a certain stress level.

Q. To reduce bending of a beam

Attempt All Questions sub parts from each question.

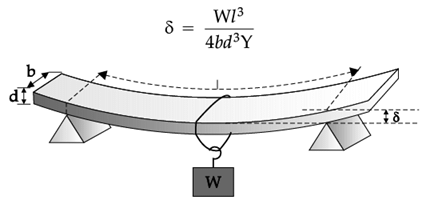

Sagging of a bridge A bridge is designed such that it can withstand the load of the flowing traffic, the force of winds and its own weight. Let us consider the case of a beam loaded at the centre and supported near its ends as shown in Figure. A beam of length l, breadth b, and depth d when loaded at the centre by a load W sags by an amount given by

From the equation, we see that to reduce the bending for a given load, one should use a material with a large Young’s modulus Y. For a given material, increasing the depth d rather than the breadth b is more effective in reducing the bending, since δ is proportional to d–3 and to b–1 (of course the length l of the span should be as small as possible).

Amongst bridge materials steel has the highest and most favorable strength qualities, and it is therefore suitable for the most daring bridges with the longest spans. Normal building steel has compressive and tensile strengths of 370 N/sq mm, about ten times the compressive strength of a medium concrete and a hundred times its tensile strength. A special merit of steel is its ductility due to which it deforms considerably before it breaks, because it begins to yield above a certain stress level.

Q. Why ductility is the special merit of steel?

Attempt All Questions sub parts from each question.

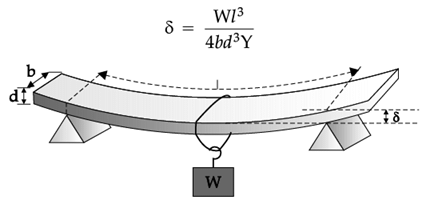

Sagging of a bridge A bridge is designed such that it can withstand the load of the flowing traffic, the force of winds and its own weight. Let us consider the case of a beam loaded at the centre and supported near its ends as shown in Figure. A beam of length l, breadth b, and depth d when loaded at the centre by a load W sags by an amount given by

From the equation, we see that to reduce the bending for a given load, one should use a material with a large Young’s modulus Y. For a given material, increasing the depth d rather than the breadth b is more effective in reducing the bending, since δ is proportional to d–3 and to b–1 (of course the length l of the span should be as small as possible).

Amongst bridge materials steel has the highest and most favorable strength qualities, and it is therefore suitable for the most daring bridges with the longest spans. Normal building steel has compressive and tensile strengths of 370 N/sq mm, about ten times the compressive strength of a medium concrete and a hundred times its tensile strength. A special merit of steel is its ductility due to which it deforms considerably before it breaks, because it begins to yield above a certain stress level.

Q. Compressive strength of normal building steel is about ................ times of the compressive strength of medium concrete.

Attempt All Questions sub parts from each question.

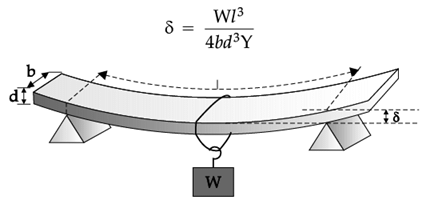

Sagging of a bridge A bridge is designed such that it can withstand the load of the flowing traffic, the force of winds and its own weight. Let us consider the case of a beam loaded at the centre and supported near its ends as shown in Figure. A beam of length l, breadth b, and depth d when loaded at the centre by a load W sags by an amount given by

From the equation, we see that to reduce the bending for a given load, one should use a material with a large Young’s modulus Y. For a given material, increasing the depth d rather than the breadth b is more effective in reducing the bending, since δ is proportional to d–3 and to b–1 (of course the length l of the span should be as small as possible).

Amongst bridge materials steel has the highest and most favorable strength qualities, and it is therefore suitable for the most daring bridges with the longest spans. Normal building steel has compressive and tensile strengths of 370 N/sq mm, about ten times the compressive strength of a medium concrete and a hundred times its tensile strength. A special merit of steel is its ductility due to which it deforms considerably before it breaks, because it begins to yield above a certain stress level.

Q. A bar of length l, breadth b, and depth d, supported at two ends when loaded at the centre by a load W sags by an amount given by

Attempt All Questions sub parts from each question.

Sagging of a bridge A bridge is designed such that it can withstand the load of the flowing traffic, the force of winds and its own weight. Let us consider the case of a beam loaded at the centre and supported near its ends as shown in Figure. A beam of length l, breadth b, and depth d when loaded at the centre by a load W sags by an amount given by

From the equation, we see that to reduce the bending for a given load, one should use a material with a large Young’s modulus Y. For a given material, increasing the depth d rather than the breadth b is more effective in reducing the bending, since δ is proportional to d–3 and to b–1 (of course the length l of the span should be as small as possible).

Amongst bridge materials steel has the highest and most favorable strength qualities, and it is therefore suitable for the most daring bridges with the longest spans. Normal building steel has compressive and tensile strengths of 370 N/sq mm, about ten times the compressive strength of a medium concrete and a hundred times its tensile strength. A special merit of steel is its ductility due to which it deforms considerably before it breaks, because it begins to yield above a certain stress level.

Q. What is the special merit of steel over concrete is its