ESE (ME) Paper II Mock Test - 1 - Mechanical Engineering MCQ

30 Questions MCQ Test - ESE (ME) Paper II Mock Test - 1

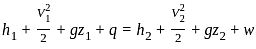

What is the drop-in enthalpy (in kJ/kg) for a steam whistle which is perfectly insulated and does not work, has an exit velocity of steam at 40 m/sec?

In a steam power plant, steam flows over the blades of an adiabatic steady flow turbine. The enthalpy at entrance was found to be 4145 kJ/kg and that at exit was 2750 kJ/kg. If the value of flow availability at entrance and exit is 1800 kJ/kg and 150 kJ/kg respectively and dead state temperature is 300 K, then calculate the change of entropy of steam in kJ/kgK. (Neglect kinetic and potential energy)

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

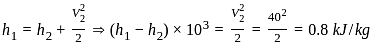

The engine of a Lexus car has three cylinders with a total displacement of 770 cc. If the compression ratio is 8.7, then each cylinder has a clearance volume of

Consider the following statements regarding tidal power generation,

1) Prediction of tides is easy

2) Power generation from tides is free from pollution

3) Tidal energy can be utilized throughout the day

4) Corrosion is a major problem

Which of the above statements are true?

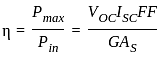

A solar cell with a surface of square cross section has a conversion efficiency 10% and is found to have an open circuit voltage of 0.5 V and a short circuit current of 0.8 A. The beam radiation on the surface is 800 W/m2 and diffused radiation is 10% of the beam. If the fill factor is 0.8, the side of the solar cell will be

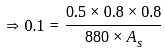

A crate of mass 100 kg is at rest on a horizontal floor. The coefficient of static friction between the crate and the floor is 0.4, and the coefficient of kinetic friction is 0.3. A force F of magnitude 344 N is then applied to the crate, parallel to the floor. Which of the following is true?

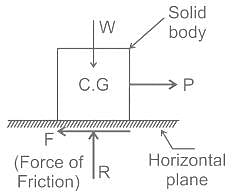

On the completion of heat treatment, If the martensite formation finishing temperature is below the room temperature, then which of the following statements is true.

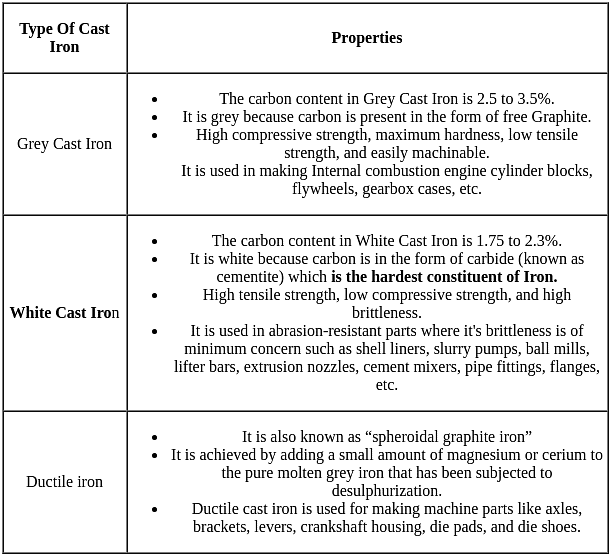

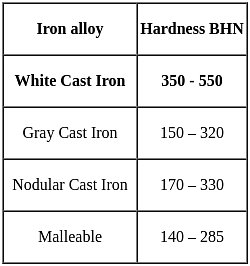

The variety of cast iron which has maximum hardness is

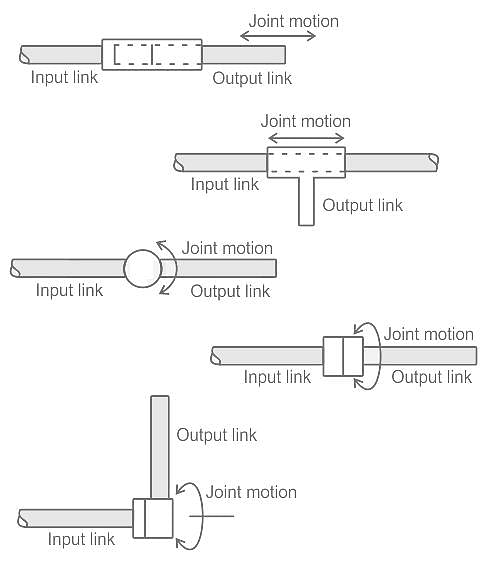

In which of the following type of robotic joint motion the angle between the two links connected changes after rotation/translation?

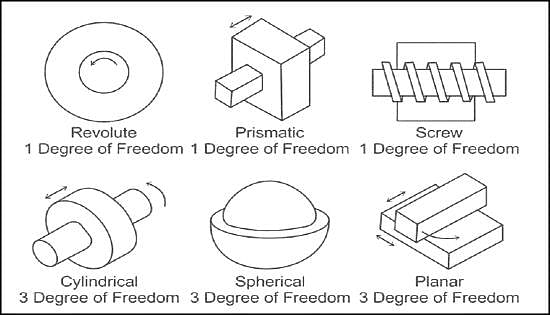

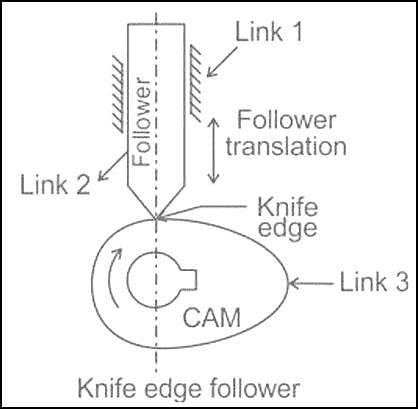

Consider the following statements regarding kinematic pairs:

1. When a pair has a point or line contact between the links, it is known as lower pair.

2. When the elements of a pair are held together mechanically, it is known as closed pair.

3. If two mating links have a turning as well as sliding motion between them, they form a screw pair.

4. When two links of a pair are in contact either due to force of gravity, they constitute an unclosed pair.

Which of the above statements are correct?

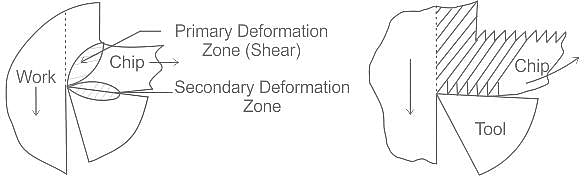

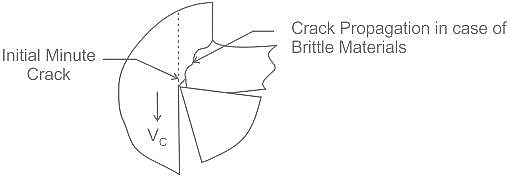

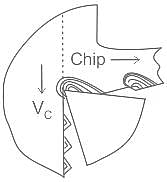

Which one of the following is formed due to large friction and stronger adhesion between chips and tool face?

Which one of the following sensors is a special type of force sensor composed of a matrix of force-sensing elements?

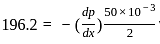

A fluid of viscosity 0.7 Ns/m2 and specific gravity 1.3 is flowing through a circular pipe of diameter 100 mm. The maximum shear stress at the pipe wall is given as 196.2 N/m2. What is the pressure gradient of the flow?

Lumped system analysis assumes a uniform temperature distribution throughout the body, which will be the case only when the thermal resistance of the body to heat conduction is

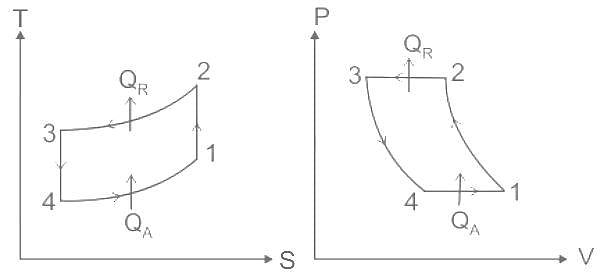

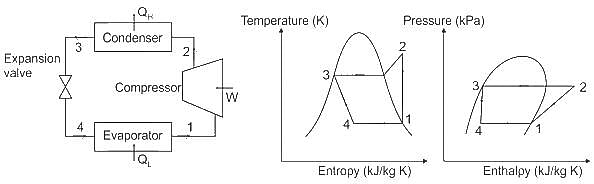

Which one of the following is used in aircraft refrigeration?

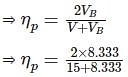

The water in a jet-propelled boat is drawn amid-ship and discharged at the back with an absolute velocity of 15 m/s. The boat speed is 30 km/hr. The cross-sectional area of the jet at the back is 0.03 m2. What is the efficiency of the jet propulsion?

Which one of the following statements is correct?

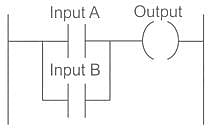

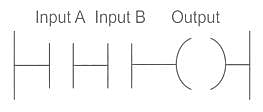

Alternative paths provided by vertical paths from the main rung of a ladder diagram, that is, paths in parallel, represent

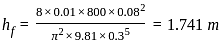

To maintain 0.08 m3/s flow of petrol with a specific gravity of 0.7, through a steel pipe of 0.3 m diameter and 800 m length, with coefficient of friction of 0.0025 in the Darcy relation, the power required will be nearly

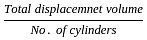

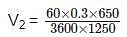

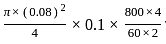

A 4-cylinder, 4-stroke single-acting petrol engine consumes 6 kg of fuel per hour at 800 rpm when the air-fuel ratio of the mixture supplied is 9:1. The temperature is 650 K and the pressure is 12.5 bar at the end of the compression stroke. Take R = 300 Nm/kg-K, diameter of cylinder as 8 cm, stroke of cylinder as 10 cm. The compression ratio will be nearly

A 13 mm diameter tensile specimen has 50 mm gauge length. If the load corresponding to the 0.2% offset is 6800 kg, the yield stress will be nearly

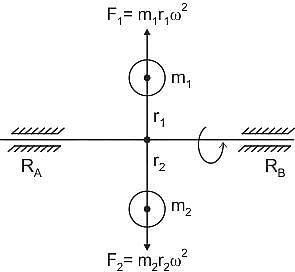

A mass m1 attached to a shaft at radius r1, rotating with angular velocity ω rad/s, can be balanced by another single mass m2 which is attached to the opposite side of the shaft at radius r2, in the same plane, if

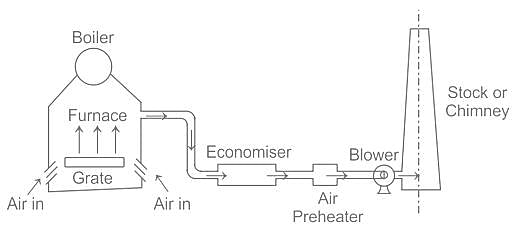

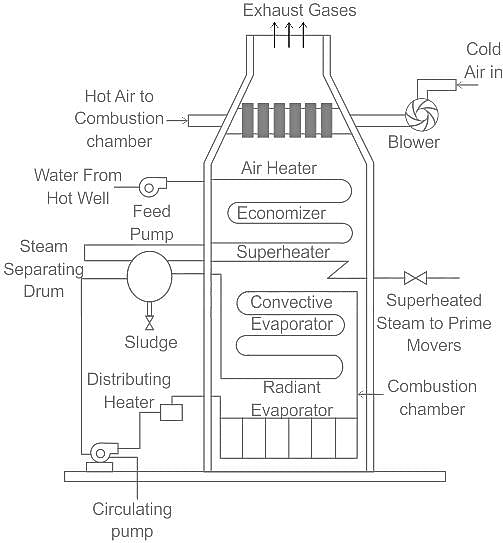

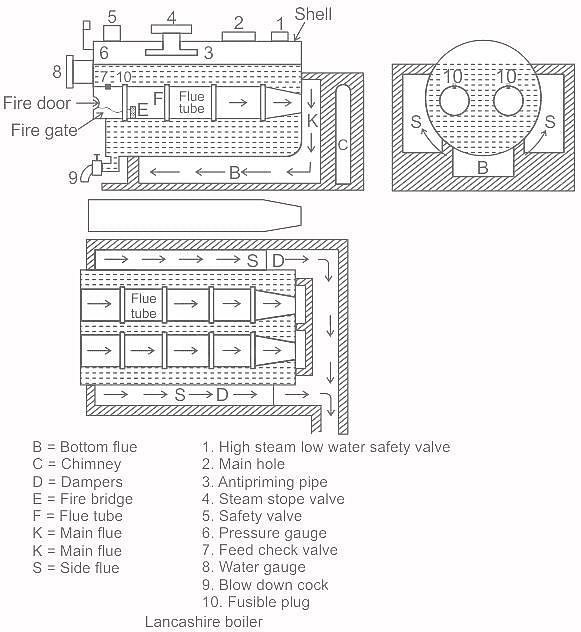

The partial vacuum created by the fan in the furnace and flues, draws the products of the combustion from the main flue and allows them to pass up to the chimney. Such a draught is called

Which of the following are related to the Proton Exchange Membrane Fuel Cell (PEMFC)?

1. Polymer electrolyte

2. Hydrogen fuel and oxygen

3. Pure water and small amount of electricity

4. Nitrogen gas

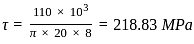

A punch is used for making holes in steel plates with thickness 8 mm. If the punch diameter is 20 mm and force required for creating a hole is 110 kN, the average shear stress in the plate will be nearly

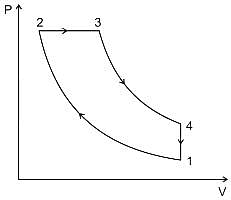

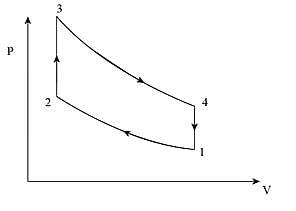

A diesel engine has a compression ratio of 20 and cut-off takes place at 5% of the stroke. What is the cut-off ratio?

The ideal hydraulic rotary actuator provides shaft torque, T, which is

= 6 kg/hr

= 6 kg/hr

= 6.153 6.2

= 6.153 6.2