ESE (ME) Paper II Mock Test - 3 - Mechanical Engineering MCQ

30 Questions MCQ Test - ESE (ME) Paper II Mock Test - 3

The heat-treatment process used to soften hard alloy and tool steels so that they can be more easily machined is called

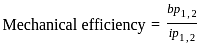

Morse test was conducted for a 2-stroke spark ignition engine having 2 – cylinders and the following data is obtained.

Brake power = 14 kW, Brake Power of individual cylinder = 5.4 kW, 4.80 kW.

What is the mechanical efficiency of this engine?

Brake power = 14 kW, Brake Power of individual cylinder = 5.4 kW, 4.80 kW.

What is the mechanical efficiency of this engine?

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Which of the following represent the Darcy’s friction factor in terms of Reynolds number (Re) for the laminar flow in circular pipes?

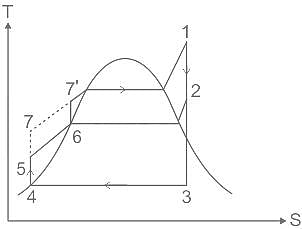

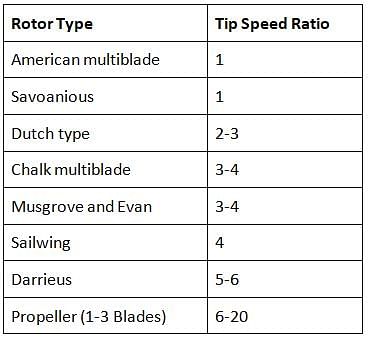

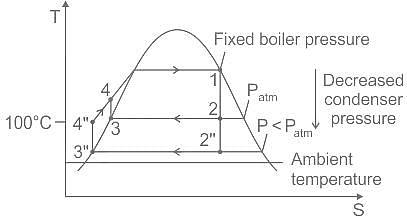

Statement (I): The thermal efficiency of a regenerative Rankine cycle is always higher than that of a cycle without regeneration.

Statement (II): In the regeneration cycle, the work output is more.

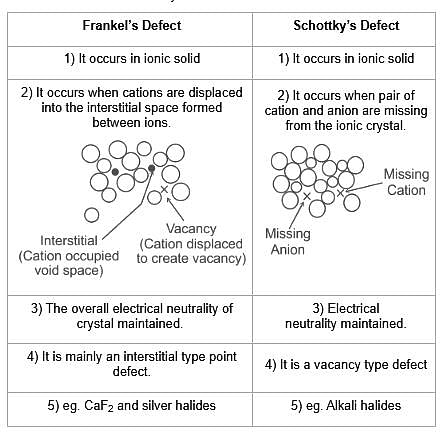

Select the correct statement about crystal defects.

1) Due to Frankel defect density of ionic solid decreases.

2) Ionic solid, with Schottky defect, contains equal number of cation and anion vacancies in their structure.

3) As the grain size of metal increases its strength decreases

Which of the following is not the correct procedure to increase the fatigue limit

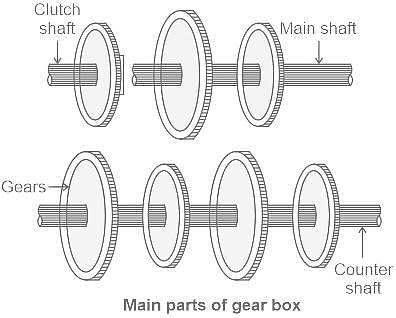

Consider the following statements regarding transmission shafts:

1. Counter shaft is secondary shaft which is driven by the main shaft from which the power is supplied to a machine component.

2. Jack shaft is an intermediate shaft between two shafts that is used in transmission of power.

3. A line shaft consists of a number of shafts, which are connected in an axial direction by means of couplings.

Which of the above statements is/are correct?

Which one of the following instructions is conditional instruction which allow the user to change the order in which the processor scans the program?

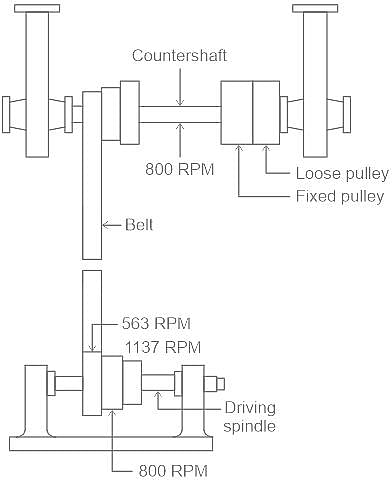

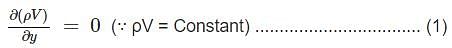

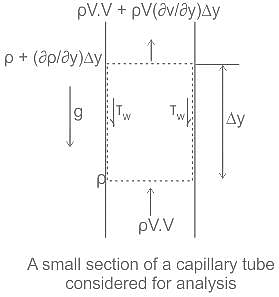

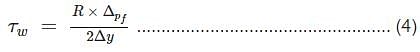

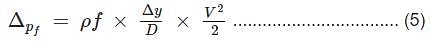

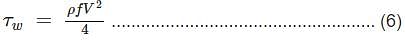

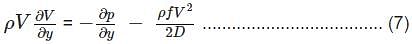

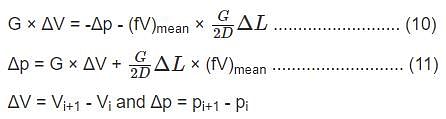

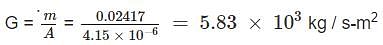

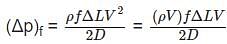

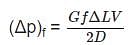

A capillary tube in a one-ton R22 air conditioner has a bore of 2⋅3 mm. Saturated liquid from the condenser enters at a temperature of 48°C and flows adiabatically through the tube until its temperature is 5°C. The friction factor is given as f = 0⋅32 / Re0⋅25. What is the length of the capillary tube? (Take intermediate sections at 40°C, 30°C, 20°C and 10°C and the mass flow rate of the refrigerant as 0.02417 kg/s)

Which one of the following fuel cells has lowest operating temperature?

Directions: Each of the next Six (06) items consists of two statements, one labelled as the 'Statement (I)' and the other as 'Statement (II)'. You are to examine these two statements carefully and select the answers to these items using the codes given below:

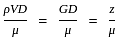

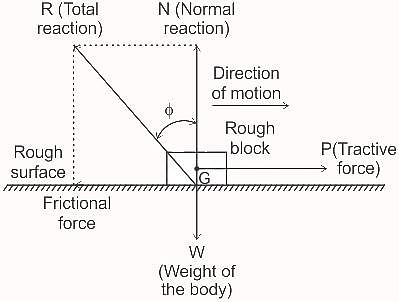

Statement (I): For moderate speed, the force of friction remains nearly constant and decrease slightly with increase of speed.

Statement (II): Friction is dependent on extent of area but independent on normal reaction.

Statement (I): Capacitive proximity sensor can only be used for the detection of metal objects and is best with ferrous metals.

Statement (II): One form of capacitive proximity sensor consists of a single capacitor plate probe with the other plate being formed by the object, which has to be metallic and earthed.

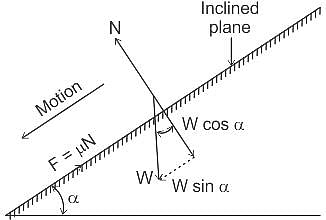

An ideal cycle based on the concept of combination of two heat addition processes, one at constant volume and the other at constant pressure, is called

A compressed air spherical tank having an inner diameter of 450 mm and a wall thickness of 7 mm is formed by welding. If the allowable shear stress is 40 MPa, the maximum permissible air pressure in the tank will be nearly

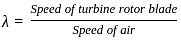

What is the tip speed ratio of savonius wind turbine rotor?

The mechanical efficiency of a single-cylinder four-stroke engine is 60%. The frictional power is estimated to be 30 kW. What is the indicated power?

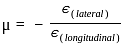

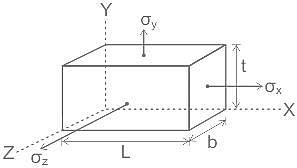

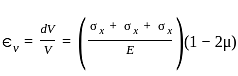

Consider the following statements for stress and strain analysis :

1. The stress components on any inclined plane can easily be found with the help of a geometrical construction known as Mohr’s stress circle.

2. The ratio of longitudinal strain to lateral strain is known as Poisson’s ratio.

3. When a body is acted upon by three mutually perpendicular forces, there is change in the volume of the body which is referred to as dilation of the material.

4. The ratio of original volume to increase in volume is known as volumetric strain.

Which of the above statements are correct ?

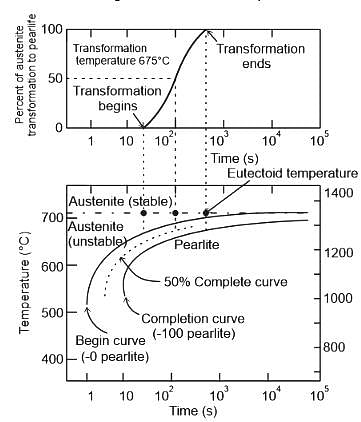

The TTT diagram shows the times required for isothermal transition from

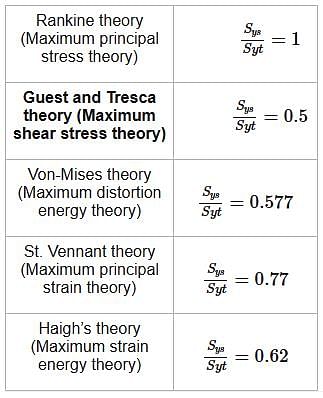

According to maximum shear stress theory, with comparison to yield strength in tension, the yield strength in shear is

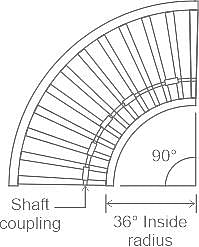

A cast steel bar having an ultimate strength of 120 MPa is subjected to a reversed, repeated, bending load. The bar will be machined to a rectangular cross-section, 150 mm wide × 200 mm high. What is the equivalent diameter?

Which one of the following contains design data on all products, e.g., their constituent components and parts ?

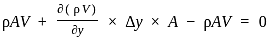

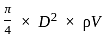

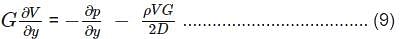

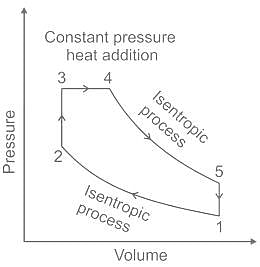

= G = constant .............................. (8)

= G = constant .............................. (8)

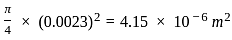

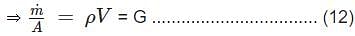

=

=

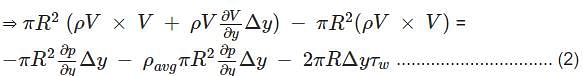

x D = 5.83 × 103 × 0.0023 = 13.409 Kg-s-1-m-1

x D = 5.83 × 103 × 0.0023 = 13.409 Kg-s-1-m-1

and A95 = 0.05bh

and A95 = 0.05bh