Test: Sheet Metal Operations - 2 - Mechanical Engineering MCQ

30 Questions MCQ Test - Test: Sheet Metal Operations - 2

Assertion (A): In sheet metal blanking operation, clearance must be given to the die.

Reason (R): The blank should be of required dimensions.

Reason (R): The blank should be of required dimensions.

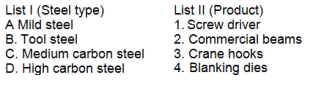

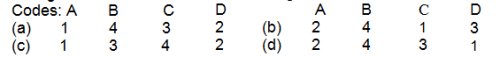

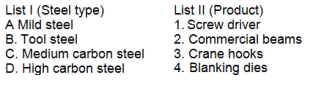

Match List I with List IT and select the correct answer using the codes given below the lists:

List I (Steel type) List II (Product)

List I (Steel type) List II (Product)

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

The force requirement in a blanking operation of low carbon steel sheet is 5.0 kN. The thickness of the sheet is ‘t’ and diameter of the blanked part is ‘d’. For the same work material, ifthe diameter of the blanked part is increased to 1.5 d and thickness is reduced to 0.4 t, the new blanking force in kN is

In a blanking operation, the clearance is provided on

The cutting force in punching and blanking operations mainly depends on

Consider the following factors

1. Clearance between the punch and the die is too small.

2. The finish at the corners of the punch is poor.

3. The finish at the corners of the die is poor.

4. The punch and die alignment is not proper.

Q.

The factors responsible for the vertical lines parallel to the axis noticed on the outside of adrawn cylindrical cup would include.

In blanking operation, the clearance is provided on

Match List (Steel type) with List II (Product) and the correct answer using the codes given below the lists:

For punching operation the clearance is provided on which one of the following?

Assertion (A): A flywheel is attached to a punching press so as to reduce its speed fluctuations.

Reason(R): The flywheel stores energy: when its speed increase.

In drawing operation, proper lubrication is essential for which of the following reasons?

1. To improve die life

2. To reduce drawing forces

3. To reduce temperature

4. To improve surface finishSelect the correct answer using the code given below:

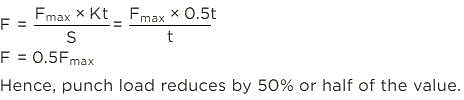

For 50% penetration of work material, a punch with single shear equal to thickness will

Match List I (Process) with List II (Production of parts) and select the correct answer using

the codes given below the lists:

Consider the following states of stress:

1. Compressive stress in flange

2. Tensile stress in the wall,

3. Tensile stress in the bottom part.

Q.

During drawing operation, the states of stress in cup would include

In deep drawing of sheets, the values of limiting draw ratio depends on

The tool for spinning copper is usually made for

For obtaining a cup of diameter 25 mm and height 15 mm by drawing, the size of the round blank should he approximately

Which one of the following metals forming processes is not a high energy rate form ingprocess?

The process of removing the burrs or flash from a forged component in drop forging iscalled:

In the deep drawing of cups, blanks show a tendency to wrinkle up around the periphery(flange). The most likely cause and remedy of the phenomenon are, respectively,

Match List- I (Item to be produced) with List-II (Process to be used) and select the correct answer using the codes given below the lists:

Codes:

A B C D A B C D

(a) 2 1 3 4 (b) 3 1 2 4

(c) 4 3 1 2 (d) 3 4 1 2

Which one of the following is a high energy rate forming process?

Identify the stress - state in the FLANCE portion of a PARTIALLYDRAWN CYLINDRICALCUP when deep - drawing without a blank holder

Match List I (Operations) with List II (Stresses induced) and select the correct answer using the codes given below the Lists:

Which one is not a method of reducing cutting forces to prevent the overloading of press?

A 2 mm thick metal sheet is to be bent at an angle of one radian with a bend radius of 100mm. If the stretch factor is 0.5, the bend allowance is

The thickness of the blank needed to produce, by power spinning a missile cone of thickness1.5 mm and half cone angle 30°, is