Test: Boiler & Steam Turbine - 2 - Mechanical Engineering MCQ

30 Questions MCQ Test - Test: Boiler & Steam Turbine - 2

The equivalent evaporation (kg/hr) of a boiler producing 2000 kg/hr ofsteam with enthalpy content of 2426 kJ/kg from feed water at temperature40°C (liquid enthalpy = 168 kJ/kg, enthalpy of vaporisation of water at100°C = 2258 kJ/kg) is

Heat is mainly transferred by conduction, convection and radiation in

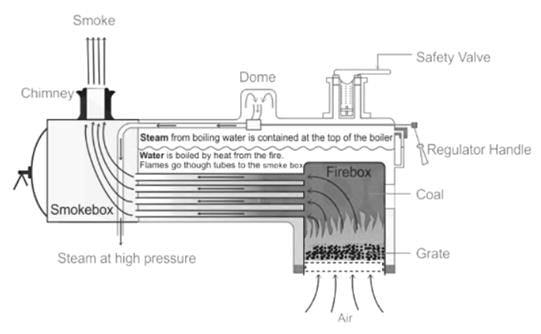

The shell diameter and length of locomotive boiler are

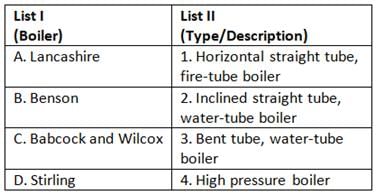

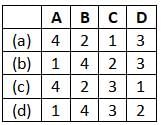

Match List I (Boilers) with List II (Type/Description) and select the correct answer using the codes given below the Lists:

Codes:

Which one of the following statements is not true for a supercritical steam generator?

Assertion (A): An 'air-to-close’ valve should be used to control the fuel supply to the furnace.

Reason (R): In the event of air failure, the valve would be closed and the fuels cut off to prevent overheating

The distinguishing feature of Velox boiler is that it

For a single stage impulse turbine with a rotor diameter of 2 m and aspeed of 3000 rpm when the nozzle angle is 20o, the optimum velocity ofsteam in m/s is

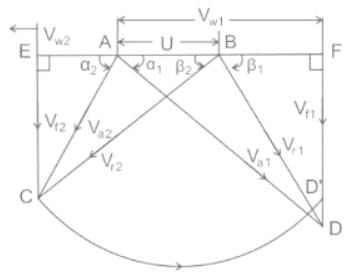

In the velocity diagram shownbelow, u = blade velocity, C = absolute fluid velocity and ω = relative velocity of fluid and thesubscripts 1 and 2 refer to inletand outlet.

Ambient air dry- bulb temperature is 45°C and wet bulb temperature is27° C. Select the lowest possible condensing temperature from the following for an evaporative cooled condenser.

In steam turbine terminology, diaphragm refers to

Which one of the following sketches represents an impulse turbine blade?

Consider the following statements in respect of impulse steam turbines:

1. Blade passages are of constant cross-sectional area

2. Partial admission of steam is permissible.

3. Axial thrust is only due to change in flow velocity of steam at inlet and outlet of moving blade.

Which of the statements given above are correct?

A single-stage impulse turbine with a diameter of 120 cm runs at 3000 rpm.If the blade speed ratio is 0.42 then, the inlet velocity of steam will be

Given, Vb = Blade speed V = Absolute velocity of steam entering the blade, α = Nozzle angle. The efficiency of an impulse turbine is maximum when

Which one of the following is used to bring down the speed of an impulse steam turbine to practical limits?

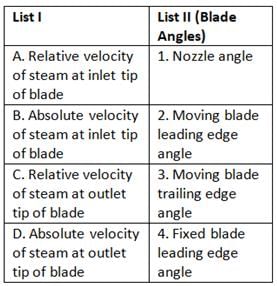

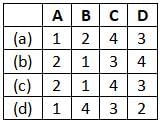

List I gives the various velocities in the velocity diagrams of a two-stage impulse turbine. List II gives the blade angles. Match the velocity from List I with the angle in List II and select the correct answer using the codes given below the lists:

Codes:

Assertion (A): Impulse staging is commonly employed in high pressure part and reaction staging in intermediate low pressure parts of the steam turbine

Reason (R): The tip leakage across moving blades is less in impulse staging as the pressure drop is small and there can be large pressure drop across fixed blades and nozzles.

Running speeds of steam turbine can be brought down to practical limitsby which of the following method(s)?

1. By using heavy flywheel.

2. By using a quick response governor.

3. By compounding

4. By reducing fuel feed to the furnace.

Which one of the following is the feature of pressure compounding (Rateaustaging)?

Which of the following statements are correct?

1. Impulse turbine rotor blades are thick at the centre.

2. Rateau turbine is more efficient than Curtis turbine

3. Blade velocity coefficient for an impulse turbine is of the order of 60%.

Assertion (A): Modern turbines have velocity compounding at the initial stages and pressure compounding in subsequent stages.

Reason (R): Excessive tip leakage occurs in the high pressure region of reaction blading.

The net result of pressure-velocity compounding of steam turbine is:

A 4-row velocity compounded steam turbine develops total 6400 kW. Whatis the power developed by the last row?

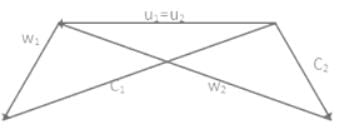

In Parson's reaction turbines, the velocity diagram triangles at the inletand outlet are which of the following?

Which of the following is the effect of frictional resistance to the flow of the steam jet over the blade in steam turbines?

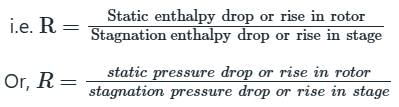

The degree of reaction for an impulse steam turbine is: