Test: Critical Speeds or Whirling of Shaft & Gear Train & Gear Design - 1 - Mechanical Engineering MCQ

20 Questions MCQ Test - Test: Critical Speeds or Whirling of Shaft & Gear Train & Gear Design - 1

In vibration isolation system, if ω/ωn, then the phase difference between the transmitted force and the disturbing force is

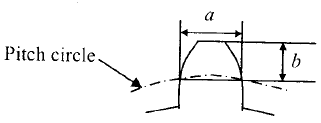

One tooth of a gear having 4 module and 32 teeth is shown in the figure. Assume that the gear tooth and the corresponding tooth space make equal intercepts on the pitch circumference. The dimensions 'a' and 'b', respectively, are closest to

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

Which one of the following causes the whirling of shafts?

In spur gears, the circle on which the involute is generated is called the

Rotating shafts tend of vibrate violently at whirling speeds because

Tooth interference in an external in volute spur gear pair can be reduced by

Critical speed of a shaft with a disc supported in between is equal to the natural frequency of the system in

The minimum number of teeth on the pinion to operate without interference in standard full height involute teeth gear mechanism with 20° pressure angle is

The critical speed of a rotating shaft depends upon

Interference in a pair of gears is avoided, if the addendum circles of both the gears intersect common tangent to the base circles within the points of tangency.

A shaft has two heavy rotors mounted on it. The transverse natural frequencies, considering each of the rotor separately, are 100 Hz and 200 Hz respectively. The lowest critical speed is

A spur gear has a module of 3 mm, number of teeth 16, a face width of 36 mm and a pressure angle of 20°. It is transmitting a power of 3 kW at 20 rev/s. Taking a velocity factor of 1.5, and a form factor of 0.3, the stress in the gear tooth is about

A shaft carries a weight W at the centre. The CG of the weight is displaced by an amount e from the axis of the rotation. If y is the additional displacement of the CG from the axis of rotation due to the centrifugal force, then the ratio of y to e (where ωc, is the critical speed of shaft and w is the angular speed of shaft) is given by

Twenty degree full depth involute profiled 19-tooth pinion and 37-tooth gear are in mesh. If the module is 5 mm, the centre distance between the gear pair will be

The critical speed of a shaft is affected by the

A 20o full depth involute spur pinion of 4 mm module and 21 teeth is to transmit 15 kW at 960 rpm. Its face width is 25 mm.

Q. The tangential force transmitted (in N) is

A 20o full depth involute spur pinion of 4 mm module and 21 teeth is to transmit 15 kW at 960 rpm. Its face width is 25 mm.

Q.

Given that the tooth geometry factor is 0.32 and the combined effect of dynamic load and allied factors intensifying the stress is 1.5; the minimum allowable stress (in MPa) for the gear material is

Number of teeth on a wheel per unit of its pitch diameter is called

A gear set has a pinion with 20 teeth and a gear with 40 teeth. The pinion runs at 30 rev/s and transmits a power of 20 kW. The teeth are on the 20c full-depth system and have a module of 5 mm. The length of the line of action is 19 mm.

Q. The center distance for the above gear set in mm is

A gear set has a opinion with 20 teeth and a gear with 40 teeth. The pinion runs at 0 rev/s and transmits a power of 20 kW. The teeth are on the 20° full –depth system and have module of 5 mm. The length of the line of action is 19 mm.

Q.

The contact ratio of the contacting tooth