Test: Casting Level - 3 - Mechanical Engineering MCQ

20 Questions MCQ Test - Test: Casting Level - 3

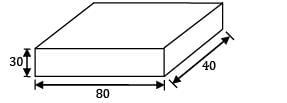

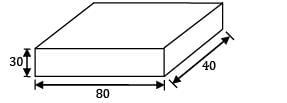

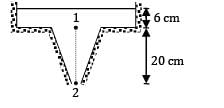

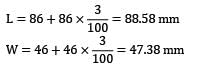

A job shown in the figure is to be made from steel by casting process. The mould for this job is made from wooden pattern. Dimensions of the wooden pattern assuming machining allowance of 3 mm on each side, shaking allowance of 1 mm on length & width & shrinkage allowance of 3%.

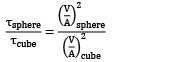

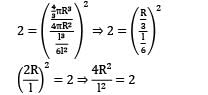

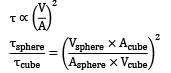

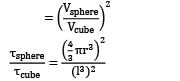

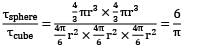

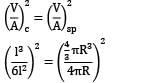

The ratio of solidification times of a sphere and cube made of same materials cast under identical conditions 2:1, are , the ratio of their volumes are __________

Metal is to be poured in a cubical cavity of 100 cm side made entirely in drag. The crosssection of the cope box is 200x 150 cm and height is 100 cm. If the densities of metal and sand are 7900 kg/m3 and 1600 kg/m3 respectively. The minimum weight required to be placed on cope in kN to prevent lifting of cope box is __________.

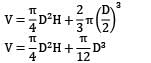

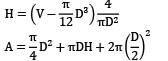

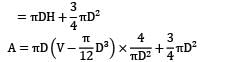

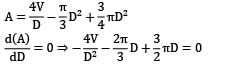

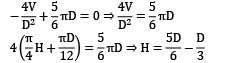

For a given volume, the ratio of height to diameter of a blind cylindrical riser with a hemispherical top for minimum cooling rate is____________.

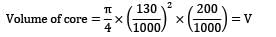

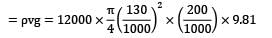

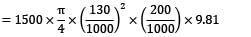

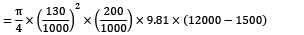

In sand casting of hollow part of zinc, a cylindrical core of diameter 130 mm and height 200 mm is placed inside the mould cavity. The densities of core material and zinc are 1500 kg/m3 and 12000 kg/m3 respectively. The net force that tends to lift the core during pouring of molten metal will be __________ N.

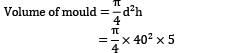

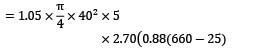

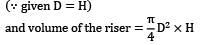

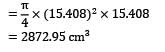

A disk of diameter 40 cm and 5 cm thick is to be casted out of pure aluminium is an open mold operation. Melting temperature of Al , pouring temperature 800

, pouring temperature 800 . Assume that the amount of aluminium heated will be 5% more than that needed to fill the mould cavity. The amount of heat (MJ) added to aluminium starting from room temperature of 25

. Assume that the amount of aluminium heated will be 5% more than that needed to fill the mould cavity. The amount of heat (MJ) added to aluminium starting from room temperature of 25 is__________. (Specific heat of Al (both cold and heated)= 0.88 J/g

is__________. (Specific heat of Al (both cold and heated)= 0.88 J/g . Heat of fusion= 389 J/g. Density Al = 2.70 g/cm3 ).

. Heat of fusion= 389 J/g. Density Al = 2.70 g/cm3 ).

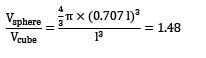

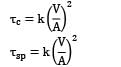

Two castings of the same metal have the same surface area. One casting is in form of a sphere and the other is a cube. The ratio of the solidification time for the sphere to that of the cube is____________.

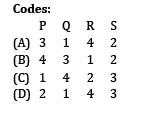

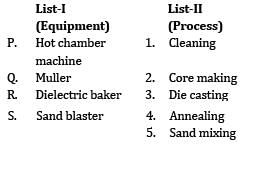

Match List-I with List-II and select the correct answer using the codes given below the lists: List-I

P. Shrinkage cavity

Q. Drop

R. Blister

S. Dross

List-II

1. This is a scar covered by thin layers of a metal

2. Lighter impurities appearing on the top surface of a casting

3. An irregularly shaped projection on the cope surface of the casting

4. An improper riser may give rise to this defect

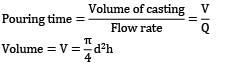

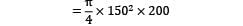

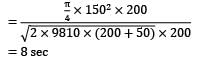

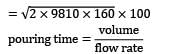

A cylinder of 150 mm diameter & 200 mm height is to be cast without any riser. The cylinder is moulded entirely in drag of a green sand flask & is top gated. The cope of flask is 200 mm height & the height of metal pouring is 50 mm above the cope. A tapered sprue is employed & the gating ratio is 1 : 1.5 : 2. The time taken _________ (in seconds) to fill the casting cavity neglecting energy losses, if the ingate area is 400 sq-mm.

A cube and sphere made of same material cast under identical conditions solidify at the same time. The ratio of length of cube to diameter of sphere is __________

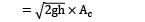

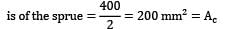

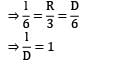

In pressurized gating system with a gating ratio 2:1.5:1. The sprue area is 200mm2 . The time taken (in sec) to fill the cavity of volume 106mm3 with a 20% metal head of 200 mm assuming a 20% loss of head in gating system is __________

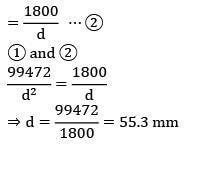

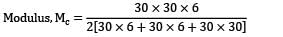

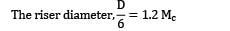

The size of a cylindrical side riser, whose height and diameter are equal, to feed a steel slab casting 30cm 30cm

30cm  6cm is ____________(Use modulus method)

6cm is ____________(Use modulus method)

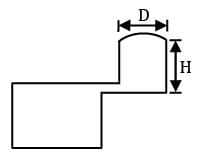

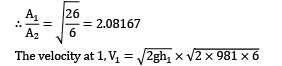

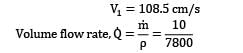

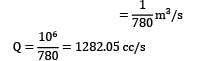

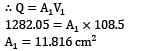

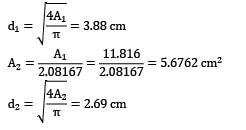

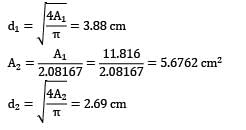

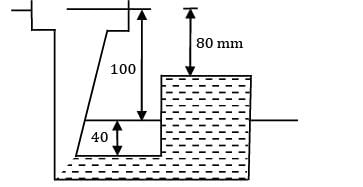

The diameter at base of a down sprue, avoiding aspiration, as shown in figure, to deliver liquid cast iron ( pm=7800 kg/m3 ) at a rate of 10 kg/s against no head at the base of the sprue (Neglecting the friction and orifice effects) is __________.(answer should be in cm)

A cylindrical riser is attached to the side of a steel plate casting having dimensions 25cm x 12.5cm x 5cm. The volume shrinkage of steel during solidification is 3% and the volume of riser is 3 times that of dictated by the shrinkage consideration alone. The dimension of the riser in optimum conditions is ____________.

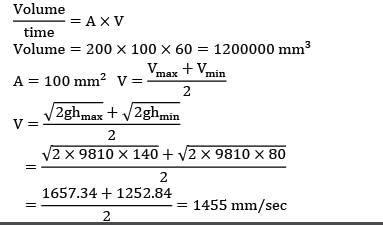

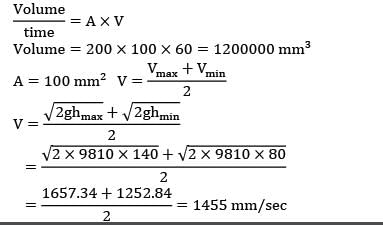

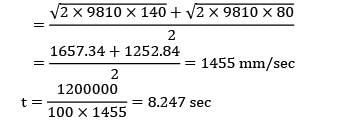

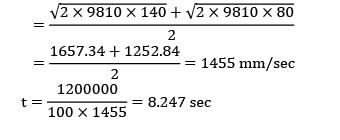

A casting of dimension 200 x 100 x 60mm is casted in such a way that 60 mm dimension is vertical and 2/3 rd of it is in drag. If the height of cope is 100 mm and cavity is fed by a bottom gate with a cross-sectional area 100mm2 , the time (seconds) taken to fill the cavity is _____________.

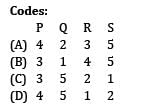

A casting of size 100cm x 100cm x 25cm was filled by top and bottom gates with manometric height in pouring basin to be 25 cm. The area of gate is 5cm2 . The difference in time (in s) to fill the casting by top and bottom gates is___________.

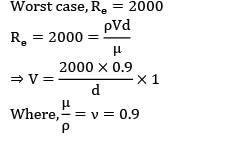

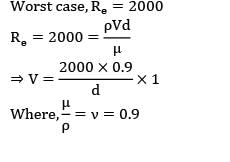

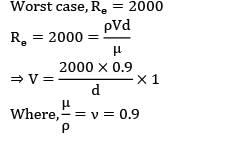

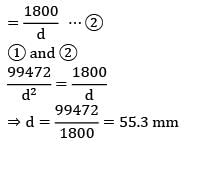

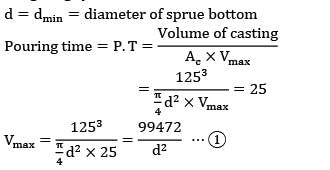

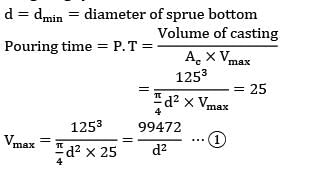

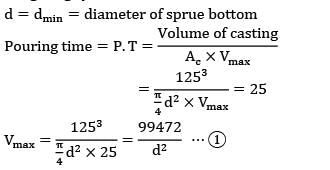

The pouring basin in a sand mould is 200 mm diameter & 100 mm height. The mould cavity is a cube of 125 mm side and must be filled in 25 second. The maximum velocity must ensure laminar flow into the mould cavity and in the gates of circular cross section.

Assume:

(A) Constant temperature,

(B) No loss in the velocity head and

(C) Diameter of gate 8 times diameter of the sprue base. Properties of the molten metal are v=0.9mm2 per second,p= 700kg/m3 and cp=33.6 J/mol-k.

The diameter of sprue to avoid aspiration effect is ____________.(fill the values of the 2 integer in between which the answer lies)

A cylindrical job with diameter of 200 mm and height of 100 mm is to be cast using modulus method of riser design. Assume that the bottom surface of cylindrical riser does not contribute as cooling surface. If the diameter of the riser is equal to its height, then the height of the riser (in mm) is

2000

2000