Test: Powder Metallurgy - 1 - Mechanical Engineering MCQ

10 Questions MCQ Test - Test: Powder Metallurgy - 1

The products made by powder metallurgy process are very strong in

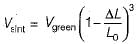

In solid-state bonding during sintering of a powder-metal green compact, the linear shrinkage is 5%. If the desired sintered density is 92% of the theoretical density of the metal, what should be the density of the green compact? Ignore the small changes in mass that occur during sintering.

Which of the following P/M products is made by impregnation?

Various additives, such as binders as in sand molds, are used to develop sufficient green strength and facilitate sintering in

he powder-metallurgy-operation consists of the following steps:

1. Blending

2. Powder production

3. Compaction

4. Finishing operations

5. Sintering

Arrange the above in operational seuquence:

Which one of the following cutting tool bits are made by powder metallurgy processes?

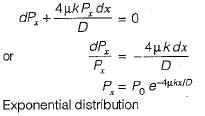

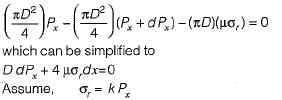

signifying a state of hydrostatic pressure.

signifying a state of hydrostatic pressure.