Past Year Questions: Extrusion And Wire Drawing - Mechanical Engineering MCQ

10 Questions MCQ Test - Past Year Questions: Extrusion And Wire Drawing

For wire drawing operation, the work material should essentially be

[ME 1987]

The process of hot extrusion is used to produce

[ME 1994]

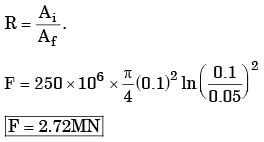

A brass billet is to be extruded from its initial diameter of 100 mm to a final diameter of 50 mm. The working temperature of 700°C and the extrusion constant is 250 MPa. The force required for extrusion is

[ME 2003]

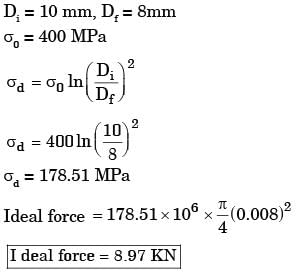

In a wire drawing operation, diameter of a Steel wire is reduced from 10 mm to 8 mm. The mean flow stress of the material is 400 MPa. The ideal force required for drawing (ignoring friction and redundant work) is

[ME 2006]

In a two-stage wire drawing operation, the fractional reduction (ratio of change in crosssectional area to initial cross-sectional area) in the first stage is 0.4. The fractional reduction in the second stage is 0.3. The overall fractional reduction is

[ME 2015,Set-2]

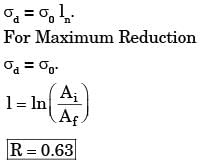

The maximum reduction in cross-sectional area per pass (R) of a cold wire drawing process is R = 1 – e–(n + 1)

where n represents the strain hardening coefficient. For the case of a perfectly plastic material, R is

[ME 2018,Set-1]

Collapsible tubes are made by

[Pl 1989]

Semi brittle materials can be extruded by

[PI 1990]

A moving mandrel is used in

[PI 1994]

The extrusion processes used for the production of toothpaste tubes is/are

1. tube extrusion

2. forward extrusion

3. impact extrusion

[PI 2004]