Test: Utilization of Electrical Energy- 1 - Electrical Engineering (EE) MCQ

20 Questions MCQ Test Electrical Engineering SSC JE (Technical) - Test: Utilization of Electrical Energy- 1

Which of the followings falls under the category of the plastic or non-fusion welding?

The proper selection of welding depends upon, in addition to cost involved:

A rectifier used for welding has voltage current characteristic as:

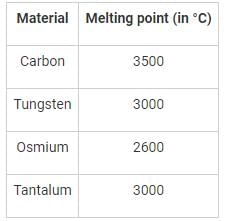

Which of the following filament material has the lowest melting point?

In electric discharge lamps, for stabilization of arc:

When a sodium vapor lamp is switched on, initially the color is:

The type of drive used for a paper mill requiring a constant speed operation and the flexibility of control is:

The least significant electrical characteristic in the selection of the electric motor for a flour mill is:

Trapezoidal speed-time curve pertains to:

For a given value of an average speed, decrease in duration of stops causes:

The most modern method for the food processing is:

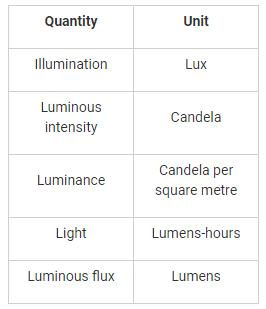

The power factor will be maximum in case of:

The dielectric loss in a dielectric is proportional to:

The supply frequency usually employed for high frequency eddy current heating is:

The process of providing an oxide film is known as:

The filtration of electrolyte is necessary:

|

23 videos|89 docs|42 tests

|